Tag: PALM OIL MILL-Processing & milling Malaysian Palm Oil Production Line

- Usage: Palm Oil

- Production Capacity: 70T~100T/D

- Voltage: 220V/380V

- Power(W): According to capacity

- Dimension(L*W*H): 1200*400*900mm3

- After-sale service: Yes

- Deodorization loss consumption: ≤0.5%

- Steam consumption: 450kg/T oil

- Bleaching earth consumption: 5~50Kg/T oil

- Business type: manufacturer

- Raw material: Palm

- Materials: Carbon steel Q235 and stainless steel

- Brand: Qi'e

Grading of FFB for palm oil mills in Malaysia 6 views; Datasheet Approximate mass balance in a 10 t hr-1 fresh fruit bunches (FFB) processing mill 5 views; Palm Oil Mill OER and Total Oil Losses 5 views; Clarification tank simulation 4 views; Datasheet PORAM standard specifications for processed palm oil 4 views

A summary of the grading standards established by Malaysian Palm Oil Board (MPOB), Sime Darby Palm Oil Mill and other experienced FFB mill graders are represented in Table 1 (Harun et al., 2013.

Palm Oil Milling & Processing Handbook

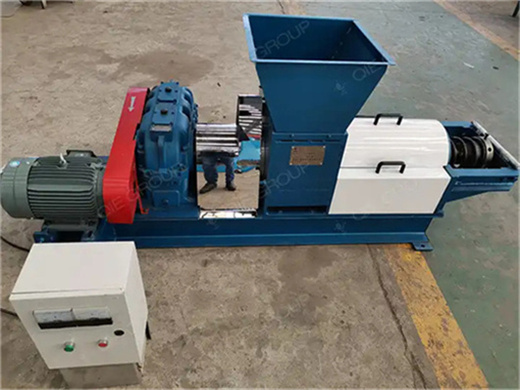

- Usage: Palm oil processing

- Type: Screw oil press

- Production Capacity: 5t/day

- Voltage: 220/380V

- Dimension(L*W*H): 1700X1200X1500mm

- Weight: 780 KG

- Warranty: 1 Year

- Key Selling Points: No slag leakage

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Squeezing snail, Squeezing cage

- Oil type: Palm oil, Rap seed oil, Palm Oil, Basil oil, Palm OIL, Pinenut oil, Palm oil

A faster determination method content in the samples of pressed fibre, sludge, steriliser condensate and empty fruit bunches in palm oil mill processing points is needed to monitor and.

Setting up a palm oil milling plant in Indonesia can be a lucrative venture, considering the country's status as the largest palm oil producer in the world. However, embarking on such a palm oil processing project requires careful planning and a thorough understanding of the costs involved.

FFB processing PALM OIL ENGINEERING BULLETIN

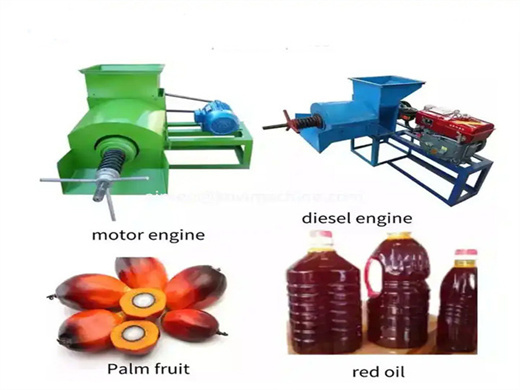

- Usage: Palm Oil

- Type: Cooking Oil Press Machine

- Production Capacity: More than 95%

- Voltage: 220V/110V

- Dimension(L*W*H): 47.5*25*41 cm

- Weight: 13.5 KG

- Core Components: Motor, PLC, Gearbox

- Oil type: Palm Oil

- Product name: Palm oil extractor pressing machine automatic

- Control mode: : automatic Palm oil press machine

- Machine Name: Palm fruit oil press

- Production: 4-6 kg/h

- Press type: Hot&cold pressing

- Advantage: with temperature control

- Product Material: stainless steel screw and chamber

- Package: Export standard carton

Processing of FFB is an unavoidable part in the production of palm oil. Evolving primitively from Africa, the basic mechanical extraction process adopted in the industry still remains. As a dynamic and progressive industry significant improvements have been achieved in the palm oil milling, both hardware and software.

The oil palm industry has proven to be one of the most important industries in Malaysia and Indonesia. As of 2009, a total of 4.69 million hectares were planted with oil palm in Malaysia, with 2.4 million hectares in Peninsular Malaysia, 1.36 million hectares in Sabah, and 0.71 million hectares in Sarawak (MPOB, 2009).

Codes Of Practice Malaysian Palm Oil Board Official Portal

- Usage: Palm Oil

- Voltage: 110V/220V

- Dimension(L*W*H): 390*150*280MM, 390*150*280 mm

- Weight: 6.5 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Gear

- Product name: Oil Press Machine

- Production Capacity: 400-6000kg/hour

- Material: 304 stainless steel

- Frequency: 50-60HZ

- Packing method: Foam box+Carton

- Mode of Operation: Mechanical Switch

CodesPractice_MPOB. Code of Good Nursery Practice Palm Nurseries; Code of Good Agricultural Practice for the Oil Palm Estates and Small Holdings; Code of Good Milling Practice for Palm Oil Mills; Code of Good Crushing Practice for Palm Kernel Crushers; Code of Good Refining Practice for Palm Oil Refineries

Printed Publication Malaysian Palm Oil Board Official Portal

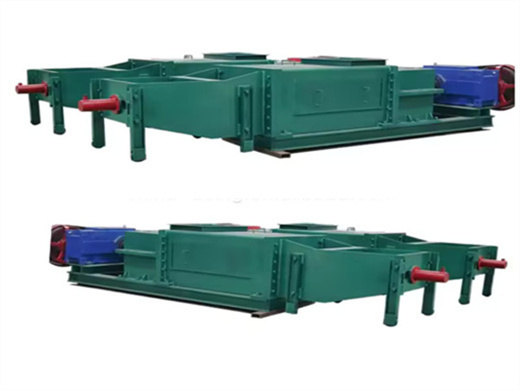

- Usage: Palm Oil, Reduce Material's Moisture

- Production Capacity: 600KG/h

- Voltage: 220/380V

- Dimension(L*W*H): 2100*1300*1600(mm)

- Weight: 1450 KG

- Warranty: 1 Year

- Key Selling Points: High Productivity

- Machinery Test Report: Not Available

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Product name: Hot Air Drying Machine

- Keywords: Fruit Vegeble Mesh Belt Dryer

- Material: Steel plate painting

- Function: Food Vegeble Fruit Dehydrator

- Advange: Low Consumption High Efficiency

- Heating source: Steam

Journal of Oil Palm Research (ejournal: 2022-present) EISSN : 28114701: 30.00: 15.00: 2. Palm Oil Developments (June 1984- June 2020) 0127-3329: 20.00: 10.00: 3. Palm Oil Engineering Bulletin (formerly known as Engineering News) 1511-9734: 10.00: 5.00: 4: Oil Palm Bulletin (November 1980-May 2022) 1511-7634: 20.00: 10.00: 5. Oil.

- What is a code of good practice for palm oil mills?

- Code of Good Milling Practice for Palm Oil Mills. Code of Good Refining Practice for Palm Oil Refineries. Code of Good Practice for the Handling, Transport and Storage of Products from the Oil Palm. requirements. that the Codes of Practice are relevant to them. range of activities. necessary for the industry to comply with.

- How many palm oil mills are there in Malaysia?

- The number of palm oil mills in Malaysia currently stands at 395, with 240 mills in Peninsular Malaysia and 115 and 40 mills in Sabah and Sarawak, respectively. Another 28 oil mills were in various stages of construction as of August 2010. Total milling capacity amounts to 89.8 million tonnes of fresh fruit bunches (FFB) annually (MPOB, 2009).

- Why is the oil palm industry booming in Malaysia and Indonesia?

- The success of the oil palm industry in Malaysia and Indonesia owes greatly to the dedication of the planters and support and encouragement from both governments. Both governments have put in place initiatives to further spur growth and competitiveness in the industry.

- How do palm oil mills work?

- Palm oil mills process palm fruit to extract palm oil. Palm oil mills can be established in close proximity to palm oil plantations, or in areas with good access to transportation infrastructure. Palm oil refineries refine crude palm oil to produce a variety of palm oil products, such as cooking oil, biodiesel, and oleochemicals.

- What are the different types of palm oil business opportunities in Indonesia?

- There are a number of palm oil business opportunities in Indonesia. These include: This is the most common type of palm oil business in Indonesia. Palm oil plantations can be established on large tracts of land, and can produce a significant amount of palm oil. Palm oil mills process palm fruit to extract palm oil.

- What is Indonesia sustainable palm oil (ISPO)?

- Indonesia is proposing to form its own Indonesia Sustainable Palm Oil (ISPO) to legislate and make it mandatory for all the oil palm plantations to be sustainable in their operation. Major plantation players such as Sime Darby and United Plantations continue to lead the CSPO production in Malaysia.