Coconut oil pressing, Our Oil Machinery

- Usage: jatropha Coconut sacha inchi

- Production Capacity: 5TPD-100TPD

- Voltage: 380V/50HZ

- Power: 5.5kw

- Dimension(L*W*H): 182*190*135cm

- Weight: 560kg

- Raw material: Coconut hazelnut Coconut

- Application: cold press oil machine

- Material: Stainless Steel 304

- Capacity: Mini

- Function: cold press oil seed machine

- Product name: blackseed oil extraction machine

- Advantage: Energy Saving

- Color: Clients' Requirements

4. Dry coconut cooking machine: Use a steam cooker, heat with steam, and use a stirring blade to mature the flakes and increase the oil yield. 5. Coconut oil pre-pressing machine: Using a screw oil press to physically extract oil from oil seeds, the oil yield rate is high, the residual oil rate in the cake is low, and the cake quality is good

QIYI Machinery's oil mill machines have an advanced and unique design, It can extract most of the oil at one time and minimize the residual oil rate as much as possible. Need assistance with your coconut oil equipment now? Do not hesitate to mail us! 3. High-Quality Parts

heat press machine oil mill machine coconut oil in bolivia

- Usage: Coconut Oil ,

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/380V

- Dimension(L*W*H): 1050*800*1400mm

- Weight: 330kg

- Warranty: 2 years, One Year

- Warranty of core components: 2 years

- Core Components: Motor, PLC

- Capacity: 100-11000kg/Hour

- Material: stainless steel and carbon steel

- Usage range: Coconut Oil ,

- Oil-content rate: less than 8%

- Wearing parts: Loops\spirals\bars

- HS CODE: 8479200000

heat press machine oil mill machine coconut oil in bolivia Machine Type: coconut oil mill machine; Production Capacity:1-200T/D; Dimension(L*W*H): 3000*2000*1600mm

Hence it is also called cold pressed coconut oil. (Read more: Virgin Coconut Oil (VCO) Extraction Plant Process) Expelled Coconut Oil Made from Copra. Extracted from dried copra Copra. The coconut is dried in the sun or in a drier before pressing the oil. The copra is then sent to a coconut extracting machine to obtain crude oil.

Premium Coconut Oil Mills for Sale at Oil Mill Machinery

- Usage: Cooking Oil

- Type: Coconut Oil Press Machine

- Production Capacity: 5-8 kg/h

- Voltage: 220V

- Dimension(L*W*H): 600*270*380mm

- Weight: 12 KG

- Core Components: Touch screen

- Oil type: Coconut Oil

- Product name: machine automatic lavender extraction mini oil press machine

- Advantage: Touch screen

- Heating: 6 grade fire

- Feature: Fully automatic operation

- Capacity: 5-8 kg/h

- Material: Stainless Steel Body

- Processing Types: Screw Pressing

- Oil rate: 96%-98%

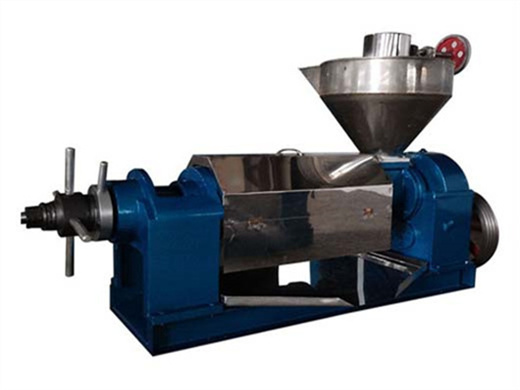

6YL series coconut oil mills are advanced oil seed presses, characterized by their high oil output rate with good quality, simple design, easy to use and continuous operation. Our coconut oil mills can also be used to process other raw material, such as peanut, beans, rape and cotton seeds, sesame, olive, Coconut, coconut, grass seed etc.

Coconut Oil Mill Machinery by TINYTECH includes Coconut Oil Expeller, Copra Cutter, Feeding Hoper / Kettle, Oil Filter Press, Electric Motor, Starter, Spare Parts, Accessories etc. It is a complete Coconut Oil Mill for getting the good quality and purest Coconut Oil. Additional Information: Production Capacity: 30 Plants Per Month

Small Coconut Oil Extraction Production Machine Starts

- Usage: Coconut Oil, Cooking Oil

- Production Capacity: 5TPD

- Voltage: 220V/380V

- Power: 5.5kw

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 800kg

- Raw material: Coconut

- Color: White

- Application: Oil Production Line

- capacity: 100-600kg/h

- Function: screw type

- Advantage: Energy Saving

- Item: Industrial Manual Oil Extractor

- quality: Coconut oil press making machine

I'm planning to start a mini coconut oil mill. please send me a qoutation and information it. Thanks; Hello, dear, For a mini coconut oil mill, the capacity is normally about 1 ton per day to 20 tons per day; The general cost of a 5tpd mini coconut oil mill plant is about $7,000 or above.

hand operated oil mill machine with and ce in bolivia

- Usage: oil filter press

- Type: oil filter press

- Production Capacity: 1-100T/D

- Voltage: 380V/440v

- Power(W): 20-50KW

- Dimension(L*W*H): depond on capacity

- Weight: depond on capacity

- Main export countries: Asia,Africa,Latin American,Malaysia...

- Packaging: Glass Container,Plastic Container

- Grade: first Grade

- refined oil: 1st grade Coconut oil

- oil content: 35%-48%

- fatty: 40~60.7

- protein: 20~37.2

- phosphlipid: 1.25~1.75

- saccharides: 5~15

- Refiney type: oil filter press

hand operated oil mill machine with and ce in bolivia Machine Type: vegetable seed oil mill machine; Production Capacity: 80kg/h-6000kg/h; Dimension(L*W*H): 2020mm*1300mm*2550mm; Voltage: 220/110V 50/60Hz; Certificate: MSDS COA; Package: Customer Require; Raw Material: vegetable seed; Market: bolivia

- What is a coconut oil pressing machine?

- Our oil pressing machines for sale are capable of processing numbers of vegetable plant and oil seeds for biodiesel or cooking uses. This machinery can not only pressing virgin coconut oil, but also can extract oil from dired copra, groundnut, sunflower seeds and other oil-bearing materials. The process of coconut oil production is not complicated.

- What is YZS coconut oil pressing machine?

- Our YZS coconut oil pressing machine is a screw type mechanical expeller press featured of easy operation and high efficient. You may use the machine to process both copra and virgin coconut. It is also suitable for making oil from other seeds or nuts, e.g. peanut, sesame seeds, soybean, etc.

- What is the oil yield of coconut oil?

- If the oil content of coconut is 65% and oil residual is 3%, the oil yield can be 98%. Oil Filter Press: Oil filter press is used for purifing the expelled coconut oil. It utilizes a fine-mesh filtering cloth. The oil under the pressure goes through the filtrating cloth, gets out from the faucet beneath the filtrating cloth.

- How is coconut oil made?

- Coconut oil is produced by cold-pressing from virgin coconut or dried coconut pulp. The oil has a low melting point of about 24 degrees, and in a cool place becomes almost dense solid. A distinctive feature of unrefined coconut oil is its aroma - the smell of fresh coconut without impurities of other odors. Coconut Oil Benefits

- What is wet processing of coconut oil?

- The wet processing uses to make virgin coconut oil (VCO) by mechanical methods at room temperature or low temperature (cold pressing), without chemical refining. No preservatives and chemical solvents are needed to keep the oil fresh and stable. This kind of processing method reduces the loss of VE, polyphenol and other nutrients.

- How hammer crushing machine is needed in copra oil processing plant?

- Crushing: Copra is big, strong and tough, unlike soya beans which break easily when moisture is low. So hammer crushing machine is needed in copra oil processing plant, and twice crushing is suggested to improve the production output. Copra Flaking: The purpose of flaking is to reduce residual oil rate.