Edible Oil Refinery Plant Manufacturers And Exporters In India

- Usage: Cooking Oil

- Type: Seed Roaster

- Production Capacity: 20-5000T/D

- Voltage: 380v 220v

- Power(W): up to equipment

- Dimension(L*W*H): up to equipment

- Weight: up to equipment

- material: stainless steel / carbon steel

- Warranty period:

- Research and development: Strong R& D team

- Engineering achievements: hundreds of projects

- Patents: 23 patents

- Residual oil rate: 1%

- Oil quality: Best grade 1 oil

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Application: Oil Production Line

During the refining process the nutritional value of the edible oil will be un effected ensuring the stability, safety and yield. The refined Oil will also not affect the health of the consumer however it ensures good digestibility by minimizing trans fats and 3 mpcd compounds.

Refining crude oil into edible oil requires deep process knowledge—from degumming, neutralization and dewaxing through to bleaching, deodorizing and GE and 3-MCPD mitigation. Edible oil producers worldwide rely on Alfa Laval know-how to remove impurities and volatile components and optimize refining processes.

Small Oil Pressing Line. Small Oil Mill Plant. Edible Oil Processing Machine

- Usage: Multi-functional

- Type: Oil refining plant

- Production Capacity: 160kg/h

- Voltage: 220V/380V

- Power(W): 4.3KW

- Dimension(L*W*H): 3750*850*1990MM

- Weight: 310

- oil refining plant: edible oil refinery equipment

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Application: Oil Production Line

- Material: Stainless Steel SS304/316

- Function: Oil refining

- Advantage: Simple Operation

- Warranty: 12 Months

- Color of oil refining plant: Customers' Request

- Cycle time: 2.5h

- Working time: 24 hours

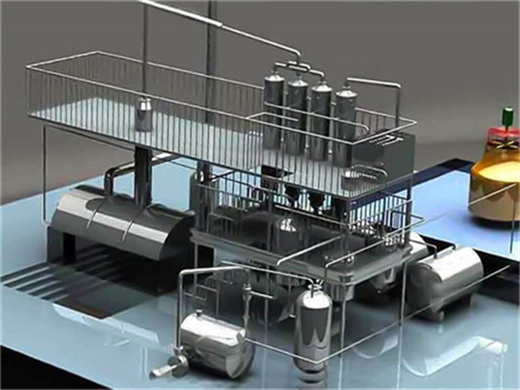

It is also suitable for filtering the bleached oil. 5. Oil Refining Equipment. Edible oil refinery plants can turn crude oil obtained from the oil press machine into refined oil with good color and high quality. The oil refining plant includes a degumming process, neutralizing process, bleaching process, and deodorizing process.

Henan Doing Mechanical Equipment Co., Ltd's product range includes a wide range of edible oil refineries and vegetable oil refinery plant, which can be divided 1-20tpd batch type edible oil refining machine, 10-50tpd semi-continuous edible oil refinery plant and 30-1000tpd full-continuous edible oil refinery plant by type.

Soybean Oil Refinery Process Optimization For High Oil Yield

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 1-1000TPD

- Voltage: 220V/380V/440V

- Power(W): According to the different capacity

- Dimension(L*W*H): According to the different capacity

- Weight: According to the different capacity

- After-sales Service Provided: Overseas service center available

- Warranty: 3 Years

- Application: Plant Seed,stem,foliage

- Processing Types: Seeds Oil Refining

- Color: as your request

- texture: SS or CS

This blog will walk you through the essential soybean oil refinery process steps, machines, and considerations for starting your own soybean oil refinery business. (Something you should know if you want to start a soybean oil refining plant>>) Start Profitable Soybean Oil Refinery Business With ABC's Support

Mini Oil Mill means a small capacity oil processing plant or even a small assembly line to meet the local market. Generally, the mini oil mill combines a series of machines together to increase the production, to achieve high oil yield and to improve the job security of workers. The whole line is easy to install, operate and commission.

Edible Oils And Fats Refining Gianazza International

- Type: Oil cake solvent extraction equipment

- Use: Oil cake solvent extractor

- Heating syetem: Conduction oil

- Steam consumption: 450kg/T oil

- Phosphoric acid: 2~3kg/T oil

- Electric consumption: 28kwh/T oil

- Deodorization loss consumption: ≤0.5%

- Circulating water cooling water yield: 150m³/H

- Bleaching earth consumption: 5~50Kg/Toil

- Waste bleaching earth oil content: <35%

- Technology guide: With guidance personnel

Different formulas have been proposed to express the loss of oil in combined refining & dewaxing processes. In COLD REFINING the acid oil obtained from soapstocks generally has an acidity in the range of 30÷50% FFA or lower. In case of crude oil with acidity higher than 1÷1,5%, the process of WET DEWAXING (combined

Palm Oil Dry Fractionation, Solvent Fractionation, Surfactant ..

- Usage: machine to refine Cooking oil

- Type: machine to refine Cooking oil

- Production Capacity: according to the specification of machine to refine Cooking oil

- Voltage: 220V/380V

- Power(W): according to the specification of machine to refine Cooking oil

- Dimension(L*W*H): according to the specification of machine to refine Cooking oil

- Weight: according to the specification of machine to refine Cooking oil

- Function: machine to refine Cooking oil

- Application: machine to refine Cooking oil

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- engineer abroad service: Yes

- factory strength: more than 30 years experience

- Spare parts: supply

- Warranty: 1year

- guide installation service: yes

- type: machine to refine Cooking oil

The current palm oil fractionation technology can be divided into: dry fractionation of palm oil, solvent fractionation of palm oil and surfactant fractionation of palm oil. This paper focus on palm oil dry fractionation technology and process.