Life cycle assessment of biodiesel production from rapeSeed Oil Processing Machine

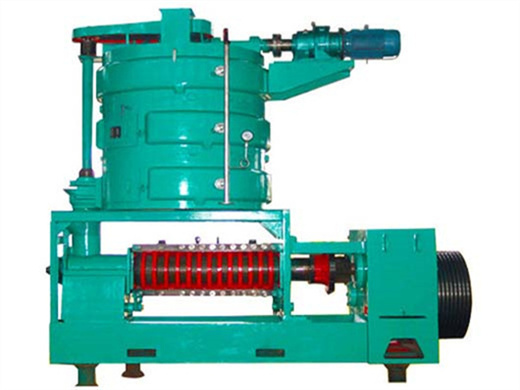

- Usage: Rapeseed OIL, All kinds of oil seeds Voltage: 380VWeight: 1300 KG, 1402kgCore Components: Motor, Pump, EngineOil type: Rapeseed OilColor: blue/Silver/customizableMaterial: carton steelPayment: L/C or T/TService: OEM and ODMPacking size: 2370mmx1320mmx1490mmAfter Warranty Service: Online support

Biodiesel can be produced from a wide variety of biomass feedstocks such as algae, raw and waste cooking oil (WCO), food waste, or animal fats (Schmidt, 2015).However, in UK approximately 50% of the biodiesel production was resourced from rapeseed oil (RO) due to its enhanced cold flow properties and oxidation stability (Mal?a et al., 2014), while fitting adequately within the UK and European

Rapeseed oil was burned to a limited extent in the Confederacy during the American Civil War. [105] Rapeseed oil was used in Gombault's Caustic Balsam, [106] a popular horse and human liniment at the turn of the 20th century. Among the more unusual applications of rapeseed oil is the calming of choppy seas, where the oil modifies the surface

rapeseed oil press production line/rapeseed in Tanzania

- Usage: Rapeseed Oil, Cooking Oil Production Capacity: 50-500kgVoltage: 220v/380v/ customizedDimension(L*W*H): 1200*780*1100mmWeight: 220 KGCore Components: MotorOil type: Rapeseed OilApplication: Screw Oil making machineRaw material: RapeseedFunction: Oil PressingAdvantage: High EfficientHeating method: electricCapacity: 30-600KG/HPress type: Screw HotFeature: Hige Oil Press RateAfter Warranty Service: Online supportFinal product: oil

Steps Involved in Rapeseed Oil ProductionThe production of rapeseed oil is the most important in the oil industry; by utilizing the seeds a company or a

The fatty acid composition of rapeseed oil is influenced by genotypic and environmental factors, with temperature being the primary environmental factor (Omidi et al., 2010). In this study, the oleic acid content in rapeseed oil generally exceeded 60 %, with the mean oleic acid content being lower in the UYR than that in the MYR and LYR.

Cold press machine and rapeseed oil extraction process

Enzymatic Deacidification and Aroma Characteristics Analysis ..

- Usage: mini Rapeseed oil mill

-

-

-

-

- Usage: Rapeseed oil Type: Rapeseed Oil Press MachineProduction Capacity: 5TPD-100TPDVoltage: 220V/380V/440V, 220V/380V/440VDimension(L*W*H): 2100*1360*1950mmWeight: 870kgKeyword: Rapeseed oil press machineRaw material: RapeseedMaterial: 304 Stainless SteelApplication range: Competitive Mini Oil Press MachineAdvantage: Energy Saving Low ResidualQuality: Top LevelItem: Edible Oil PressFunction: Oil Press + Drum Filter,Making Edible OilPower(W): 5.5/7.5Certification: ISO9001,CE

- What is rapeseed oil production process?

- The production of rapeseed oil is the most important in the oil industry; by utilizing the seeds a company or a person is able to get well refined oil that has to go certain steps in order to suit the market. The process involves extraction of oil from the seeds. Rapeseed oil production process is the third in production of vegetables oils.

- How do you cook rapeseed flakes?

- Flaking includes rupturing the rapeseeds to allow oil to get in the flake and then they are cooked at 75 to 85 temperatures in the roasting equipment. Then they are passed through screw pressing, in which screw oil press equipment is used to press the small flakes into sizeable particles.

- What is rape seed pretreatment?

- Pretreatment for Rape Seeds This is the process where the seeds are prepared for extraction of oil; the process utilizes energy to rapture or make the walls of the seeds weak. This energy can be obtained through mechanical way by grinding, breaking, rolling, pelleting and pressing the seeds.

Rapeseed oil is a widely consumed edible oil that contains varieties of beneficial micronutrients such as tocopherols and phytosterols; however, the high acid value due to increased free fatty acid can imperil the oil quality and safety. This paper proposed the enzymatic deacidification for high-acid rapeseed oil and simultaneous production of functional diacylglycerols (DAGs) catalyzed by

Rapeseed Morphology Parameters Influencing Oil Pressing GCIRC

the oil yield. If the dependence of the oil yield on the fiber content at constant seed moisture is known for a couple of different varieties, it will be able to estimate the yield of oil of other varieties to ±2% absolutely. The rule is: The lower the seed moisture and the higher the fiber content, the greater the relative oil yield.