Biodiesel Production: An Overview and Prospects

- Usage: Cooking Oil

- Capacity: 20tpd-100%

- Voltage: 220V/50HZ

- Dimension (L*W*H): 450*180*310

- Weight: 11kg

- Function: Manufacture of edible oil

- Raw material: sunflower, soybeans, peanuts, sesame, etc.

- Advantage: Savings of energy

- Material: 304 stainless steel

- Oil grade: food grade

- Capacity: 2- 3kg/H

- Application: Oil production line

Biodiesel has emerged as a promising alternative to fossil fuels due to its renewability, biodegradability, and potential for reducing greenhouse gas emissions.

The biodiesel production process is extensively studied in the literature, focusing on mechanisms, modeling, and economic aspects, yet plant design and fluid flow losses remain underexplored areas.

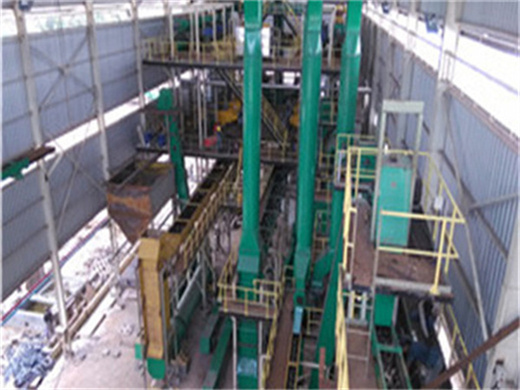

Biodiesel Production Equipment Magtech TM

- Usage: Cooking Oil

- Capacity: 12-15 TPD

- Voltage: 40 HP

- Dimension (L*W*H): 2121t1400t2743

- Weight: 5500 KG

- Main components warranty: 5 years

- Main components: motor, bearing, gearbox

- Oil type: cooking oil

- Oilseed extraction: cooking, cotton, sunflower, cooking, Cooking, Sunflower

- Gearbox: Double reduction gearbox

- Capacity: 15 tons per 24 hours

- Motor: 40 HP

- Cooking pot: Single and multi-stage

- Bearings: Heavy duty

- Chamber: Chamber made of steel

- Augers and cage bars: Long useful life

- Certification: ISO 9001-2008

List of Biodiesel Production Equipment. Biodiesel production involves transesterification of used oils and fat to form fatty acid methyl esters or FAME. It also produces glycerol as a by-product. Hence, the biodiesel production equipment comprises important components that conduct this reaction, purify FAME and separate glycerol.

This review paper highlights the production of biodiesel from different plant based feedstocks via the transesterification process. Biodiesel is a renewable, non-toxic, environment-friendly and an

Biodiesel Production Techniques Oklahoma State University

- Usage: Cooking Oil

- Capacity: 100% cooking oil machine

- Voltage: 220V/380V/440V

- Power (W): 5.5 ~ 18.5 KW

- Dimension (L*W*H): 1950*1300*1900, according to capacity

- Weight: 950KG

- Certification: ISO9001/CE/BV

- Raw material: Vegetable seed

- Name: cooking oil machine

- Application: Oil pressing

- Common capacity: 80-600kg/h

- Warranty: One year

- Character: Screw oil pressing machines

- discoloration time: 15-20 min

- Humidity: 3%

- residual oil in cake: 2%

Biodiesel production requires a feedstock (fat or oil) and an alcohol. In most cases, a catalyst also is present. Figure 1 shows a schematic diagram of the unit operations involved in biodiesel production.

This means that all process chemicals must be accounted for and waste must be minimized. Commercial producers must incorporate recovery of excess chemicals and recycling into their plant designs. Commercial-Scale Biodiesel Processing. Figure 1 shows a schematic diagram of the processes involved in commercial-scale biodiesel production.

Chapter 2 Introduction to Biodiesel Production Line

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Capacity: 250-300 KG/H

- Voltage: 380V

- Power (W ): 3KW

- Dimension (L*W*H): 2000x1200x2500mm

- Weight: 2200 kg

- automatic oil press machine: oil extraction machine

- Material: 316 stainless steel

- Barrel diameter: 40 cm

- Cake oil rate: 3%

- Pressure: 35 -50mpa

- Advantage: Energy Saving

- Color: Customers' Requirements

- Raw materials: Soy, sesame, Cooking, Cooking, coconut

- Furniture: Yes

properties of biodiesel must be the same, complying with the requirements set by international standards. 2.2.1 Typical Oil Crops Useful for Biodiesel Production The main characteristics of typical oil crops that have been found useful for biodiesel production are summarized in the following paragraphs [6?10]. 2.2.1.1 Rapeseed and Canola

Emerging technologies for biodiesel production: Processes ..

- Usage: Cooking Oil

- Capacity: 400~600 kg/h

- Voltage: 220V/380V

- Power (W): 18.5 kW

- Dimension (L*W*H): 1500 *1600*2500mm

- Weight: 2000kg

- Raw material: soybean , peanut, rapeseed, sesame, sunflower seeds

- Advantage: energy saving

- Machine material: stainless steel part

- br>Residual : Less than 5%

- Type of business: manufacturing

Although different reviews such as reactor technologies for biodiesel production [27], diverse features of biodiesel derived from various oil feedstocks [28], improving biodiesel production through enzymatic catalysts [29], and development of the biodiesel industry [30] have been published on biodiesel production, the current review focuses on

- How biodiesel is produced in Indonesia?

- Biodiesel produced in Indonesia mainly uses the trans-esterification method. Here is the process flow of trans-esterification: Purification Crude Palm Oil (CPO) is cleansed, and odor is eliminated, which will then be refined to produce Refined, Bleached, and Deodorized Palm Oil (RBDPO).

- What plants are used in biodiesel production in Indonesia?

- Irma noted that in Indonesia there are a number of plants that can be used as the raw materials for the biodiesel production. The plants include oil palm trees, coconut, castor plant, moringa, candlenut, and others. “But why we use mostly palm oil? It’s because we’re rich in palm oil as we’re the world’s largest producer of palm oil,” said Irma.

- How does Indonesia support biofuel production?

- The Indonesian government mostly supports biofuel production through issuing regulations, pushing state-owned enterprises, or providing subsidies, such as the BPDPKS for biodiesel and conventional ethanol using the state budget. Table 2. Biofuel production pathways status in Indonesia

- How does Gar produce biodiesel?

- This is far above canola, the second most productive crop, where 1 hectare of canola can only produce around 0.8 tonne of oil. At GAR, we produce biodiesel from sustainable palm oil using the trans-esterification method. This is how it works:

- Does Indonesia have a biofuel policy?

- In 2004, the Indonesian government developed a biofuel strategy under the National Energy Policy, and it was released as part of Presidential Regulation No. 5/2006, which promoted both biodiesel and bioethanol production.1 Since then, the government has issued several more regulations to support the policy.

- Is biodiesel made from palm oil?

- Among others, biodiesel is often manufactured from palm oil. As the most productive source of vegetable oil, 1 hectare of land planted with oil palm can produce up to 3.5 tonnes of oil. This is far above canola, the second most productive crop, where 1 hectare of canola can only produce around 0.8 tonne of oil.