Edible Oil Refinery Machines for coconut,sunflower,peanut oil

- Usage: Peanut Oil

- Production Capacity: 100% Peanut expeller

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity

- Weight: Depand on your capacity

- Raw material: Peanut

- Application: Peanut oil Pressing

- Common capacity: 1-2000TPD

- Character: semi-auto, automatic

- Certificate: CE/BV/ISO9001

- Advantage: high oil yield

- Flowchat: cold press/hot press/prepress/solvent extraction

In the pursuit of healthier cooking oils and sustainable living, small-scale edible oil refinery machines emerge as invaluable assets. These compact yet powerful devices are revolutionizing the process of refining edible oils, offering individuals and small businesses the opportunity to produce high-quality oils with minimal environmental impact.

In general, there're 3 types of peanut oil refinery plant, batch type, semi-continuous and full-continuous. 1-2-3-5-10TPD batch type peanut oil refinery plant. 10-15-20-25-30-50TPD semi-continuous peanut oil refinery plant. 50-80-100-150-300-600-2000TPD full-continuous peanut oil refinery plant. Different capacity peanut oil refinery machine

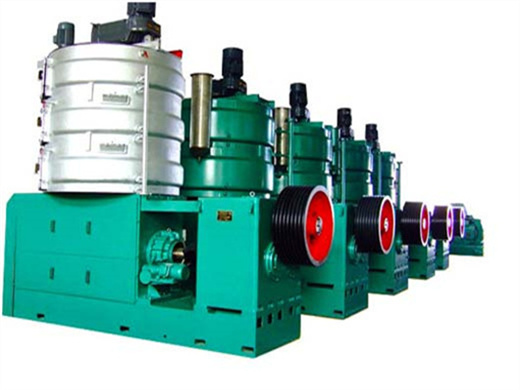

Special Discounted High Quality Business Price Peanut Oil Mill

- Usage: Peanut Oil

- Type: Peanut oil production line

- Production Capacity: 80kg/h, 500kg/h, 100kg/h

- Voltage: 380V/50HZ

- Power(W): depend on the capacity of Peanut oil machine processing

- Dimension(L*W*H): depend on the capacity of Peanut oil machine processing

- Weight: depend on the capacity of Peanut oil machine processing

- Material: Stainless Steel And Carbon Steel

- Raw material: Peanut

- Peanut fruit reception system: Sterilizer

- Distillation range: 68-75℃

- Indine value: 44-46gl/100g

- Transparency: 500c

- Acid value: less than 1.0mg koh/g

- Crude oil moisture and volatile: Less than 0.30%

- Spare parts: Supply

Complete solution for Batch & Continuous type Edible Oil Refinery Plant. Edible oil refining, A collective name for a series of processes that remove solid impurities, free fatty acids, phospholipids, colloids, waxes, pigments, odors, etc. contained in vegetable oil.

Machine Type: edible oil refinery machine, Production Capacity: 5T-10T/D, Dimension(L*W*H): 1190X680X1720mm, Power: 370W, material for machine: carbon steel and stainless steel, Dry Cake Residul Oil Rate:

2000t sunflower oil refinery plant in qatar

- Usage: Cooking Oil

- Type: Oil Extraction Machine

- Production Capacity: 1 ton/day

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 4.26 *1.55 *3.52 ft

- Weight: 0 KG

- Warranty: One year warranty against manufacture defect.

- Oil type: Peanut Oil

- complete Warranty Service: Video technical support

- on site Warranty Service: Field maintenance and repair service

- Raw material: Oil Seeds

- Function: Making Edible Oil

- Product name: Screw Press Oil Expeller

- Application: Edible Oil Production

- Used for: Edible Oil Making

2000t sunflower oil refinery plant in qatar Machine Type: sunflower oil refinery plant; Production Capacity: 5000 Sets/Year; Motor Dimensions: standard; Voltage: 380V, depend on the capacity; Certification: CE ISO, ISO9001,BV,CE; Motor: new oil expeller with water cooling system motor; Raw Material: sunflower; Market: qatar

It is a small refining equipment used to refine edible oil and oil. It can also be called the refining equipment of edible oil. The oil refiner can remove the impurities in the edible oil and make the edible oil have a longer storage period, better color and smell, and more green and healthy.This equipment can produce high-cooking oil or salad oil.

How to refine crude peanut oil to edible oil?__Vegetable Oil Processing Machine

- Usage: Peanut OIL, Cooking Oil/Peanut Oil

- Type: Oil press

- Voltage: 220V/110V

- Dimension(L*W*H): 450*180*300mm

- Weight: 12 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Engine, Gearbox

- Oil type: Peanut Oil

- Raw material: Peanut/Oleander

- Function: Press Oil Seeds

- Product name: Peanut Oli Press

- Application: Peanuts, oleander, pepper seed, Peanut

- Advantage: High Oil Yield

- Capacity: 50-700kg/h

- Material: 304 Stainless Steel

From crude peanut oil to standard edible oil needs to go through four basic stages of degumming, deacidification, decolorization and deodorization. Next, I will introduce the refining process of peanut oil in the order of the work sections. Crude peanut oil refining machine. Step1. Degumming

large crude peanut oil refined mill machine in qatar

- Usage: Peanut Oil, Cooking Oil

- Type: Peanut Oil Press Machine

- Production Capacity: 800KG/H

- Voltage: 380V/50HZ

- Dimension(L*W*H): 2670*1000*1726mm

- Weight: 1800kg

- Core Components: Gear, Bearing, Gearbox

- Oil type: Peanut Oil

large crude peanut oil refined mill machine in qatar Machine Type: peanut oil refined machine; Production Capacity: 50~100T/D; Dimension(L*W*H): 2180*800*1790mm

- What is edible oil refinery technology?

- Edible Oil Refinery technology include soybean /rapeseed / cottonseed /peanut sunflower seed /corn germ /rice bran etc. Skip to content Home About Company Profile Manufacture Base Certificates Customer Case Service Technology Oil & Fats Pressing&Preparation Soybean Peanut Sunflower Corn Germ Cotton Seed Rape Seed Rice Bran Palm Kernal

- What is refining in edible oil processing?

- Refining is the last step in edible oil processing. We are committed to making every drop of oil safe, healthy and nutritious. Value-adding by-products may be produced from processing stages like Degumming, Neutralization, Bleaching, Dewaxing/Winterization and Deodorization.

- How many oil refineries does myande supply?

- Worldwide, Myande has supplied more than 500 oilseed crushing lines and more than 150 cooking oil refinery lines, including 30 cooking oil refinery production lines with capacity above 800t/d and 20 oil refinery production lines with capacity above 1,000t/d.

- What is the purpose of neutralizing edible oil?

- The purpose of neutralizing is to remove free fatty acid, phospholipids, gums or solids in edible oil by using caustic soda. We offer solutions featuring higher oil yield and lower energy consumption. Bleaching process removes coloured matters, residual pesticides, metal ions by mixing bleaching earth with edible oil.