The circular bioeconomy of the olive oil industry ..

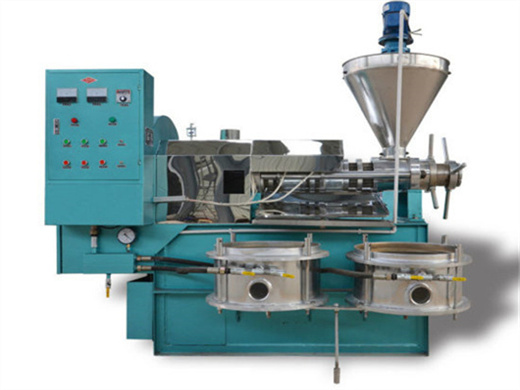

- Usage: Edible Oil

- Voltage: 380V-415V

- Power (W): depends on oil machine mode

- Dimension (L*W*H): depends on oil machine mode the oil machine

- Weight:depends on the mode of the oil machine

- Certification:CE,BV,ISO9001

- item:oil presser

- production process:pretreatment, extraction, refining

- raw material:many types of vegetable oil seeds

- Bleaching earth residue Oil content:25% to 35%

- Electric consumption: 28Kwh/T of oil

- Water softening: 150Kg/T of oil

- Phosphoric acid: 2~3 kg/T of oil

- Bleaching earth consumption:80-500KG/T oil

- Supplier Steel material: stainless steel or carbon steel

The circular bioeconomy of the olive oil industry: Deterministic and probabilistic profitability of olive mill by-product gasification September 2024 Biomass and Bioenergy 189:107350

As the plant capacity increases in scale to over 34.64 million kg of annual soybean oil production, the break-even is met and the producing stream is able to earn profits.

Layout Design Elevate Modern Palm Oil Factory Plant ..

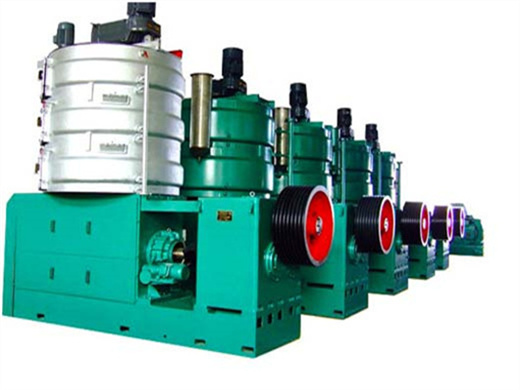

- Usage: Cooking Oil

- Certification: ISO CE

- Product type: cooking oil expeller machine

- Residual oil in cake: 1%

- Keyword: cooking oil expeller machine

- Solvent: n-hexane

- Voltage: 380 V or 440 V

- Application: cooking oil expeller machine

- Extractor type: rotocel extractor

- Dimension (L*W*H): according to capacity

Palm Oil Refinery and Fractionation Plant Layout. 1. Located At The End Of The Production Line Considering that crude palm oil refining process and palm oil fractionation process are the final steps in palm oil production, placing these two areas at the end of the production line helps to facilitate the transportation of the final product from the mill to the warehouse.

Mini Oil Extraction and Refining Machines for Complete Oil Mill Plant. To build an oil mill factory for cooking oil production, oil extraction machine and edible refinery machine are necessary investment. Many customers, especially those who needs to buy these equipment from other countries worry about to buy inferior equipment at high price .

Various Activities of Oil Mill GOYUM Oil Expeller and Oil Refinery Machine

- Usage: Cooking Oil

- Voltage: 220V/380V/440V

- Power (W): 22kw

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Weight: 30 tons

- Certification: ISO CE

- Name: Ivory Coast 10TPH Cooking Fruit Oil Pressing Machine

- Name of the Product: Cooking fruit oil press machine

- Advantage: 40 years experience

- Technology: new design

- Application: Oil production line

- Production period: 45 days

- Installation period: 60 days

- Supplier type: manufacturer

- Technology support: lifetime

This filtration takes place by pumping the oil to the filter press. Where it passes through a layer of the filter cloth. The liquid oil passes through the filter cloth and solid matter deposits on the filter cloth. There are two important types of filter presses, generally used in oil mill industry.

In the profitability analysis of the soybean oil extraction process, the total capital investments of extruding-expelling process, hexane extraction, and EAEP are 26.6, 41.0, and 7.6 million dollars (2015 price) based on 30.8, 22.4, and 0.1 million kg of annual soybean oil production respectively.

Vegetable Oil Refinery Plant: The Ultimate Process

- Usage: Edible Oil

- Capacity: 1t/day-1t/hour-100%

- Voltage: 110V/220V

- Dimension (L*W*H)): 52 .5*24.5*30 cm

- Weight: 12 KG

- Main components: Motor

- Oil type: Cooking oil

- Product Name: Oil Pressers

- Raw Material: Vegetable Seeds

- Function: Oil Pressing

- Advantage: Simple operation and high oil yield

- Material: Stainless steel

- Shelf life: 6-8 years

- Name: Home use cooking oil making machine

- Word key: oil press machine

An oil expeller plant specifically presses or expels the oil from seeds, delivering an unrefined product ready for purification. Setting Up the Edible Oil Refinery Plant. The edible oil refinery plant receives crude oil after it has been obtained. This stage is critical for refining the oil to meet food-grade standards.

Mini Oil Mill Business Project Cost, Machine Details,

- usage: To Extract Oil From Various Oilseeds & Nuts.

- Model number: GMS-SJ700

- Voltage: 380V

- Power (W): 39kw

- Weight: 200kg

- Dimension (L*W*H): 1500*900*1900mm

- Material: 304 Stainless Steel

- Application: glass jars, canned food, etc.

- Control system: automatic

- Sterilization form: Hot steam

- Function: High temperature and high pressure sterilization

- Work quality : Safe

- Design temperature: 147 degrees Celsius

- Capacity: 120-150 kg

- Processing types: autoclave sterilization of glass bottles

Mini oil mill comes under small-scale industries. Their production capacity ranges from 10 15 Kg per day. A mini oil mill project costs less when compared to medium and large-scale oil mills. The project cost of a mini oil mill plant depends upon things like

- Is there an adequate site for a landfill in Kabwe?

- Finding an adequate site for the landfill is now on critical path, because the design consultants are expected to be on board shortly; the project team is discussing this issue with the Kabwe Municipal Council and Department of Lands and Forests.

- How to develop appropriate small-scale oil production technology?

- development of appropriate small-scale oil production technology thus becomes imperative. To develop suitable appropriate systems, a multidisciplinary approach is required. This should entail in the study of not proposed locality where the oil palm product ion venture is envisaged. processing technologies.

- How much money does oil palm cultivation make per hectare?

- ried between IDR 44 million and IDR 295 million per hectare. The measure of return to labour showed that oil palm cultivation can potentially provide returns to labour that are 2 to 7 times higher than the average agricultural wa

- Are palm oil mill effluents anthropogenic?

- Palm Oil Mill Effluents (POME) are complex fermentative substrates which habour diverse native microbial contaminants. However, knowledge on the microbiota community shift caused by the anthropogenic effects of POME in the environment is up to date still to be extensively documented.

- Is small-scale palm oil processing possible in Africa?

- Poku, K. (2002), Small-scale palm oil processing in Africa. Agricultural Services Bulletin 148, Food and SAHEL Newsletter (2015). Unlocking the Palm O il Potential in West Africa. Vol 10. landscapes and livelihoods. Global Food Secu rity 1 114 –119 Central Local Government Area of Osun Sta te, Nigeria. Journal of Social Sciences, 10 (1): 55-59

- What is palm oil mill effluent?

- Palm oil mill effluent (POME) is characterised by high colour, COD and solids. Extraction and drying of the suspended solids for reuse as solid fuel shows great promise. However, the clarified wastewater may require further treatment to meet discharge limits.