Soybean Oil Mill / Oil Extraction Plant Manufacturers

- Usage: crude Soybean oil refinery

- Production Capacity: 5T~15T/D

- Voltage: 380V

- Power(W): 25KWh/T

- Dimension(L*W*H): 1200*400*900mm3

- Material: stainless steel and carton steel

- Steam consumption: <280KG/T (0.8MPa)

- Business type: manufacturer

- Crude oil moisture and volatile matter: <0.3%

- Item: crude Soybean oil refinery

- Raw material: Soybean

- Operating pressure: normal/negative pressure

- Dimension: depending on capacity

Soybean Oil Extraction Process. Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

The pretreated soybean flakes are sent to the soybean solvent extraction plant. The soybean oil extraction plant uses a kind of solvent (normal hexane) to absorb the oil from the soybean, and then the machines separate the solvent from soybean crude oil. The solvent can be recycled, and the soybean crude oil is refined by an oil refinery plant.

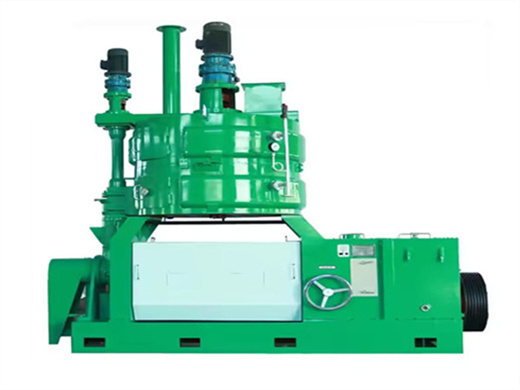

Soybean Solvent Extraction Plant Oil Expeller and Oil Refinery Machine

- Usage: Soybean Oil, Soybean EDIBLE OIL

- Production Capacity: 1-300ton per day

- Voltage: 380v,440v,customized

- Dimension(L*W*H): depends on the capacity

- Weight: depends on the capacity

- Warranty: 1 Year, 1year

- Raw material: pressed oil,Soybean oil......

- Function: cooking /edible

- Advantage: high oil quality, Environmentally friendly

- Feature: High Oil Yield Efficiency

- processing: chemical & physical

- Material: stainless steel or carbon steel

- Processing Types: automatic

Due to the specific qualities like Unsaturation and highly suitable cooking oil, salad oil and in the production of mayonnaise. Sunflower Seed Oil Extraction. Soya bean Oil Extraction by Solvent extraction method is most popular and commercially viable economic solution and accepted world wide. Commercial standards of Soya beans

Soybean Oil Extraction. Commercial soybean oil extraction is a complex process. The traditional method for soybean oil extraction was a mechanical process using hydraulic presses. Because it was expensive and produced lower yields, the mechanical production process has given way to production by means of extraction with solvents.

Soybean Oil Leaching Process to Produce Crude Oil

- Usage: edible oil

- Type: whole edible oil refinery plant

- Production Capacity: 100%

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): various with capacity

- Weight: changed with capacity

- Raw material: Soybean

- Product: to make crude oil or refined oil

- Capacity: from 1T to 30T edible oil refinery plant

- Oil content in oilseeds: about 20-50%

- Oil residues: less than 1%

- Function: getting refined oil

- Manufacturing experience: 40 years experience in edible oil field

- Material of equipment: stainless steel and carbon steel

QIYI Machinery Soybean Oil Solvent Extraction Plant. In soybean oil processing, choosing the right production process is crucial to ensure the quality of the oil and improve the production efficiency. Among them, the oil solvent extraction method is more suitable for large-scale commercial soybean oil production plants, as well as investors who

Advantages of Screw Oil Pressing:The mainly advantages of screw pressing type oil extraction plant by means of oil expeller is better adaptability, flexible production, high quality of the oil, light color, pure flavor, simple technology, few supporting equipment.

Soybean Seed Processing, Oil Extraction & Refining Plant

- Usage: Soybean Oil

- Type: Cold & Hot Pressing Machine, Famous Brand Soybean Oil pressing machine/ production line/ plant

- Production Capacity: 10-5000T/D

- Voltage: 220V/380V/410V

- Power: 2.2KW

- Dimension(L*W*H): 1910*550*765 mm

- Weight: 420 KG

- Function: Refining Soybean oil

- Material: SS/CS

- Application: Soybean,etc.

The extraction process uses hexane or other solvents to wash the soybean oil from the prepared soybean flakes. The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth needed to efficiently wash the flakes, the contact time of the solvent and flakes, and the power and utilities needed to run the equipment.

Equipment and turnkey plants for oilseeds crushing and Oil Processing Machine

- Usage: Soybean Oil extraction process

- Type: Soybean Oil extraction process

- Production Capacity: 20-2000TPD

- Voltage: 380v

- Power(W): 15kw

- Dimension(L*W*H): 430*230*350

- Weight: 2-10t

- Material: stainless steel and carbon steel

- Color: customerization

- Labor need: 1staff

- End product: crude oil and cake

- Raw material: Soybean

- Package: container special for shea butter extractor

- Delivery: within 60 days after the payment

- Payment: TT, L/C

- Residual: less than 1%

That is why we offer oil extraction plants tailored to a variety of oilseeds. Our plants have capacities ranging from 100 t/d to 10,000 t/d, and can handle oilseeds such as soybean, rapeseed, sunflower seed, cottonseed, rice bran, peanut, corn germ, PKC (palm kernel cake), sesame, flaxseed, coconut, linseed, niger seed, shea nut, copra, avocado

- Which countries produce soybean oil in the world?

- The major Soybean producing countries in the world are USA, Brazil, Argentina, China, India, Uruguay, Ukraine, Bolivia, Nigeria, South Africa Complete Turnkey 60 TPD Soybean Oil Mill Installed in Ethiopia Feel free to inquire for detailed information about soya bean oil extraction plant and soybean oil mill machinery.

- How to set up a soybean oil mill plant?

- Here we have listed some of the basic machinery required to set up Soybean Oil Mill Plant Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration.

- What are the advantages of soybean extruder technology?

- Advantages of Extruder Technology: Soybean obtained after the preparatory process can be used as a raw material for Soybean Oil Extraction. The soybean contains 18 – 20 % oil content. After a single stage pressing, about 5 – 5.50% residual oil in the soybean meal which will be used in animal & poultry feed.

- What is the process of soybean oil extraction plant?

- Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

- How many TPD is a soybean processing plant?

- We provide small scale to large scale soybean processing plants capacity starting from 15 TPD. Soybean, also called soya bean or soja bean. The oil content in the soybean is between 18% – 20% depending on the variety of seeds.

- How to extrude a cracked soybean?

- The cracked soybeans are heated to about 150° C – 170° C in a time span of 10 – 15 seconds. This sudden heating helps achieve the premium grade full fat extruded soybean. Advantages of Extruder Technology: Soybean obtained after the preparatory process can be used as a raw material for Soybean Oil Extraction.