crude sesame oil refined process machine in lagos

- Usage: Sesame Oil, Cooking Oil

- Type: Sesame Oil Press Machine

- Voltage: 220v/380v/ customized

- Dimension(L*W*H): 1200*780*1100mm

- Weight: 220 KG

- Core Components: Motor

- Oil type: Sesame Oil

- Heating method: electric

- Raw material: Sesame

- Capacity: 30-600KG/H

- Function: Oil Pressing

- Application: Screw Oil making machine

- Advantage: High Efficient

- Feature: Hige Oil Press Rate

- Final product: oil

- Press type: Screw Hot

KMEC can help you with information about the sesame oil production process. If you have any questions on sesame oil manufacturing or how to start a sesame oil mill, contact KME C for more details, we are always ready to help you! Below is a small scale complete sesame oil mill project we set up overseas. Small Sesame Oil Extraction Unit for

The conventional process for sesame oil extraction machine includes: (1) cleaning, (2) dehulling, (3) roasting, (4) grinding and (5) oil extraction, respectively (Fukuda and Namiki, 1988). Roasting is a critical stage which influences color, composition, and organoleptic qualities of the extracted oils as well as oxidative stability ( Yen and Shyu, 1989 ).

Heavy Metals In Sesame Seed (Sesamum Indicum) Determination

- Usage: Sesame Oil

- Production Capacity: 1-1000TPD

- Voltage: 220V/380V

- Power(W): 5.5kw

- Dimension(L*W*H): 1.5*2.6*3.6M

- Weight: 30tons

- Keywords: Sesame oil expeller

- Color: Silvery White

- Function: to achieve oil

- Feature: High Output

- after shipment

- Processing Types: Semi-automatic

- Material: Steel

- Application: Crude Oil Extraction

- Advantage: High Oilput

- Application range: Sesame..etc

extraction, Crushed sesame seed mixture in the soxhlet extractor was put placed inside a heating mantle and subjected to heating for 2 hrs. The extracted solid was removed from the apparatus by filtration to obtain the extracted lipids. The crude oil was obtained after the solvent extraction subjected to refluxing at 60 o C to remove the excess

Enzyme extraction Sesame oil extraction can be improved by adding enzyme to water solution. Sesame oil can extract by demanding different enzymes like papain, Tripsin and cellulase. Enzyme extraction in neutral condition i.e. at 50° C, 3hr, 80 rpm, enzyme amount were 6000,400 and 250U/g is %58.87. Total conclusion

Sesame Seed ( Til Seed ) Solvent Extraction Plant Process

- Usage: Sesame Oil

- Type: For Sesame fruit oil pressing machine usage

- Production Capacity: 10-3000 TPD

- Voltage: 380V 440v

- Power(W): As Sesame fruit oil pressing machine output every day

- Dimension(L*W*H): AsSesame fruit oil pressing machine capacity

- Weight: Depend on Sesame fruit oil pressing machine output

- Item: Sesame fruit oil pressing machine

- material: Stainless steel

- moisture in meal: less than 8.0-9.0%

- solvent residual: less than 0.07%

- index in crude oil: 50-500ppm

- the bed height: try to make it higher

- method of Sesame: Sesame and Sesame

- usual extractoin ways: solvent extractoin and pre-pressing extraction

- mixed oil concentration: 18-25%

- degree of Sesame oil factionation: 8 ,16 ,24 ,32 degree

The cooled and sized cake will be transferred to Solvent Extraction Process to extract the balance oil of 17% plus leaving the residual oil less than 1% in cake. Method 2 : Full Press Full press itself indicating that the seed is totally pressed to drain out maximum oil.

Sesame meal, as a main byproduct of sesame oil extraction, is usually discarded, causing resource waste and economic loss. Sesame meal is rich in sesame protein and three types of sesame lignans

Optimizing Sesame Oil Extraction Process

- Usage: Sesame Oil, automatic

- Type: Sesame Oil Extraction Machine

- Production Capacity: 10tpd-100%

- Voltage: 220V/110V

- Dimension(L*W*H): 46*26*36CM

- Weight: 100kg

- Oil type: Sesame Oil

- Material: Stainess Steel

- Raw material: Sesame

- Model: DL-ZYJ03C

- Function: Oil Production

- Advantage: High Oilput

2013. The extraction and characterization of sesame oil was carried out by solvent extraction using n-hexane as the solvent. Output yield evaluated as a function of temperature, contact time and different particle sizes gave an average of 44.80 % oil yield.

Groundnut Oil Extraction Machines Product Delight

- Usage: Sesame Oil

- Production Capacity: 1-1000TPD

- Voltage: 220V/380V

- Power(W): 5.5kw

- Dimension(L*W*H): 1.5*2.6*3.6M

- Weight: 30tons

- Keywords: Cold pressed extra virgin Sesame oil

- Color: Silvery White

- Function: to achieve oil

- Feature: High Output

- after shipment

- Processing Types: Semi-automatic

- Material: Steel

- Application: Crude Oil Extraction

- Advantage: High Oilput

- Application range: Sesame..etc

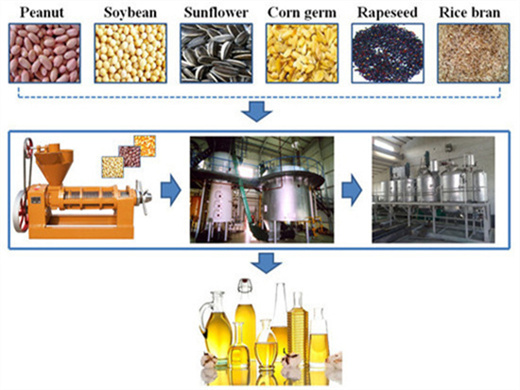

It is not difficult to use at all and can be used to extract oil from different seeds such as sunflower, soybean, groundnut, sesame, etc. Groundnut Oil Extraction Process There are three main stages when it comes to groundnut oil extraction and they are; Seeds Preparation, Pressing and Refining. Seed Preparation

- What are the different types of sesame oil extraction methods?

- Sesame oil extraction methods categorizes in two groups; laboratory method and industrial method including, Hot water flotation, Ram Press, Ghani Process, pressing method, subcritical liquid method, soxhelet method, fractionation, and enzyme extraction. The amount of extracted oil and time are different in this method.

- How to extract sesame oil?

- In this method as much as fine seeds consumed, obtained oil has better quality. Extraction is performed through adding water (%11-13 w/w), the resulted paste dried at 70°C (Warra et al, 2011). Modern methods using normal hexane and enzyme extraction. Sesame oil extraction by subcritical CO2 has reported as well.

- What are the processing methods of sesame oil?

- All processing methods including refining of sesame oil obtained from crude seeds (with/without husk), fried oil resulted from fried sesame, sesame oil produced from non-husk fried sesame seeds (Hwan, 2005). Husk peeling is essential as a result of the presence oxalic acid and non-digestible fiber.

- How to extract sesame seeds?

- Sesame seeds smashed through a plate with mesh 2mm. In this method as much as fine seeds consumed, obtained oil has better quality. Extraction is performed through adding water (%11-13 w/w), the resulted paste dried at 70°C. In this method, there is no need to initial grounding,however beginning on metal sheets.

- What are the methods used in the production of sesame seeds?

- Efficiencies of hot water floating, poly press, ram press, Ghani process, subcritical liquid, soxhelet, fractionation, and enzyme methods were %41, %70, variable, %26.47%, %34.23, %58.93 and %58.87 respectively. Sesame is one of the agriculture crops which are estimated belonging to over 4000 years ago.

- How to extract sesame oil by subcritical CO2?

- Sesame oil extraction by subcritical CO2 has reported as well. Grounded sesame seeds forms to a paste, heats to 80°C-90°C for 15min, then shakes while boiling for 15min, after cooling, upper layer removes and dried by heating, efficiency of this method is %41 Sesame seeds smashed through a plate with mesh 2mm.