Commercial Rice Bran Oil Extractor Extraction Automatic Oil Pressers Machine To Make Rice Bran Oil

- Usage: Rice Bran Oil mill machine Type: Rice Bran Oil mill machineProduction Capacity: 35-550kg/hPower(W): 1.5KWDimension(L*W*H): 900*850*1550Weight: 6-800kgCertification: ISO9001Item: Rice Bran Oil mill machineModel: 6YY-230 900*850*1550(L,W,H)Production Handling capacity: 35-550kg/hMain engine: Y901-4-1.5KWElectric heating coil temperature: 70-100鈩?/td>

One option to add value to this agricultural waste is by utilizing the potential phytochemicals in rice bran oil (RBO). Rice bran oil contains vital chemicals with medicinal and nutritional benefits. This paper examines the numerous ways that rice bran oil is extracted, the various phytochemicals that are present, as well as their potential for

Solvent Extraction Plant RUNGTA INDUSTRIES PVT. LTD One of the leading manufacturers of Rice bran Oil in eastern UP Know More WELCOME TO RUNGTA INDUSTRIES Rungta Industries Pvt. Ltd. was incorporated in the year 2005. The solvent extraction plant was formed in the same year. Our company is a private body under the directorship of

Rice Bran Oil Solvent Extraction Process Detailed Guide

- Usage: Rice Bran Oil, Rice Bran EDIBLE OIL Type: Rice Bran Oil Press MachineProduction Capacity: 10-12t/24h Plant Oil Extraction MachineVoltage: 220V/380VDimension(L*W*H): 2350*840*1850Weight: 1700 KGCore Components: Motor, PLCOil type: Rice Bran OilProduct name: Press Rice Bran Plant Rice Bran Oil MachineApplication: Making Hot Rice Bran Mill Rice Bran OilFunction: Rice Bran Oil Extraction MachineCapacity: 10-12t/24hScrew Diameter: 130mmUseage: Plant Oil Extraction MachineCity: Zheng Zhou

Due to the low oil content in rice bran, most factories use this method for its large output and high economic benefits. (Read more: rice bran oil refinery plant. >>) Four Steps of Rice Bran Oil Solvent Extraction Step1: Rice Bran Oil Extraction. In this initial step, the rice bran is mixed with a solvent, typically hexane, in an oil extractor.

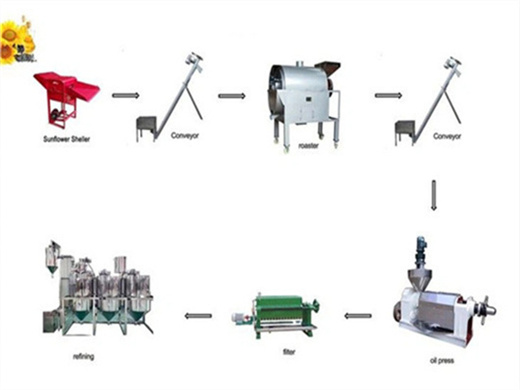

rice bran oil processing plant includes rice bran pretreatment & extrusion workshop, oil solvent extraction plant and Oil Refinery Plant. Hua County Henan Province, China +8615937289608 [email protected]

Improving the solvent-extraction process of rice bran oil

- Usage: Rice Bran Oil, Rice Bran EDIBLE OIL Voltage: CustomizedWeight: 1600 KGWarranty: 1 Year, One Year's GuaranteeWarranty of core components: Not AvailableCore Components: Motor, Gear, GearboxOil type: Rice Bran OilProduct name: Oil mill machineryRaw material: Vegetable Oil SeedsApplication: Edible Oil ProductionFunction: Screw Pressing Oil SeedsMaterial: Hardened SteelAdvantage: Simple OperationColor: CustomerizedQuality: China Profesional Oil Press MachineOperation: 1-2 Person

The pilot-plant extraction of rice bran oil was assessed. The solvent-extraction and associated processes were simulated. Results and field data are shown to be in good agreement. Energy optimization was performed using pinch technology and gas membrane technology. Nearly 50% of energy can be saved in comparison with the

During the extraction process, the solvent penetrates into the rice bran granules and combines with the oil, which diffuses from the rice bran granules into the solvent . The oscillating extraction method can promote the diffusion of oil from the surface of the raw material into the solvent as quickly as possible to reach a uniform state.

Rice Bran Solvent Extraction Plant

- Usage: Oil seeds Type: Complete lineAutomatic Grade: ManualProduction Capacity: 10-30 tonsVoltage: 380V/3 phasePower(W): According to capacityDimension(L*W*H): 1200*400*900mm3Certification: CE & ISO, ISO-9001 and CESupplier type: ManufacturerManufacturing experience: 19 yearsHandling capacity: 10-30 tons/24hService life: 20-25 yearsMaterials: Rice BranFinal product: Edible/salad oilProduction period: 55 daysInstallation period: 60 daysMain market: Asia, Africa and Oceania

The solvent extraction method is the most commonly process in the market, the residual oil rate is less than 1%. A full range of advanced rice bran oil processing solution, including raw material pretreatment technology, solvent extraction technology, physical refining technology and rice bran protein processing technology, recover higher quality rice bran protein, HongDe Machine is

Kamal Solvent Extractions Pvt. Ltd

- Usage: Rice Bran etc Production Capacity: 5TPD-100TPDVoltage: AC220V,50HZDimension(L*W*H): 54.5x29x71cmWeight: 70 KGCore Components: MotorOil type: Rice Bran OilProduct name: Mini Oil Press Machinecapacity: 20kg/h raw materialsoutput: 8-1000kg/h oilcontrol mod: cold&hot pressingMaterial: stainless steelPacking size: 70*45*65CMPacking quantity: 1 piece in a cartonGross weight: 70kgWork time: keep working 12 hoursRaw materials suitable: Rice Bran etc

Kamal solvent extraction Pvt. Ltd. is a rice bran oil manufacturing unit established by entrepreneurial vision of Mr. Damodar Das Mundra. Established in the year 1989, with an installed capacity of 50TPD, which was later expanded to 150 TPD & is presently having an operational capacity of 500 TPD.

- How to extract rice bran oil?

- There are several techniques used for the extraction process of the Rice bran oil, but solvent extraction using hexane is the most popular used conventional process for commercial extraction. Rice bran oil expelling relies on very high-quality Rice bran oil expellers.

- How does rice bran oil refinery work?

- After cleaning, the rice bran is conditioned to prepare it for oil extraction. This involves adjusting the moisture content and temperature of the bran to achieve the ideal conditions for oil release. Proper conditioning enhances the efficiency of the rice bran oil refinery process by ensuring the bran is at its optimum state for extraction. 3.

- What are the benefits of conditioned rice bran oil refinery?

- Proper conditioning enhances the efficiency of the rice bran oil refinery process by ensuring the bran is at its optimum state for extraction. 3. Palletization: The conditioned rice bran is compressed into pellets during the palletisation step. This step not only facilitates uniform solvent penetration during extraction but also minimizes wastage.

- What is the yield of oil from rice bran?

- The yield of about 92% of the oil was obtained from the hexane extraction process of ohmic heating-stabilized rice bran. About 42.7 to 99.9% yield of oil from rice bran using ethanol to rice bran ratio of 2.5:1 and 4.5:1, and temperature of 60-90°C.

- What is conditioned rice bran?

- The conditioned rice bran is compressed into pellets during the palletisation step. This step not only facilitates uniform solvent penetration during extraction but also minimizes wastage. Rice bran oil output increases when bran is pelletised because it guarantees a more efficient and regulated extraction process. 4. Pellet Cooler:

- How to make rice bran oil from rice husk?

- When refers to Rice bran oil production, the following three processing steps are important they are raw material preparation, Rice bran oil extraction, and crude oil refining. Like other oil bearing materials, before making oil from rice husk, these raw materials must have been fully prepared.