rice bran solvent extraction plants Rice Bran Oil Solvent ..

- Usage: Rice Bran OIL, Cooking Oil Production Capacity: 5TPD-100TPDVoltage: 220V/380V/440VDimension(L*W*H): depend on capacity, depend on capacityWeight: 230 KG, 230KG-2000KGCore Components: Motor, Pressure vessel, Gear, BearingOil type: Rice Bran OilName: Rice Bran oil press machineMaterial: Stainless Steel 304Certification: ISO9001,CERaw material: Rice Bran, soyabean, Rice BranPower(W): 5.5/7.5Function: Oil Press + Drum Filter,Making Edible OilCapacity: 80-500kg/hAdvantage: high oil quality

While initial setup costs can be significant, solvent extraction plants can be economically viable in the long run due to their high efficiency and yield., Rice bran oil solvent extraction plant,Solvent extraction of rice bran oil,,Rice bran oil extraction process,Rice bran oil production plant,Solvent extraction technology for rice bran oil,Rice bran oil extraction equipment,High efficiency

Rice bran oil is the only cereal oil that is produced in large quantity. During rice milling, the bran is obtained and the bran has an oil content of 18-20%. Rice bran oil can easily be obtained in direct solvent extraction of the rice bran. But due to the powdery nature of the rice bran, rice bran oil production requires a preparation before

Kamal Solvent Extractions Pvt. Ltd

- Usage: Oil press production line Type: Edible oil extruderProduction Capacity: 100-500 Ton oil per dayVoltage: AdjustableCertification: ISO CEOil grade: Grade 1Residual oil in meal: ≤ 1%Steel type: Carbon steel or 304 steelFinished meal moisture: ≤ 10-13% (adjustable)

Kamal solvent extraction Pvt. Ltd. is a rice bran oil manufacturing unit established by entrepreneurial vision of Mr. Damodar Das Mundra. Established in the year 1989, with an installed capacity of 50TPD, which was later expanded to 150 TPD & is presently having an operational capacity of 500 TPD.

crude rice bran oil solvent extraction plant in addis ababa . Production Capacity: 20t/24h; Voltage: 380V; Dimension(L*W*H): 2670*1008*1726mm; Weight: 1800kg

Rice Bran Extraction Plant Professional Supplier Of Oil Processing Machine

- Usage: Oil press production line Type: Edible oil extruderProduction Capacity: 30-500 Ton oil per dayVoltage: AdjustableCertification: ISO CEOil grade: Grade 1Residual oil in meal: ≤ 1%Steel type: Carbon steel or 304 steelFinished meal moisture: ≤ 10-13% (adjustable)

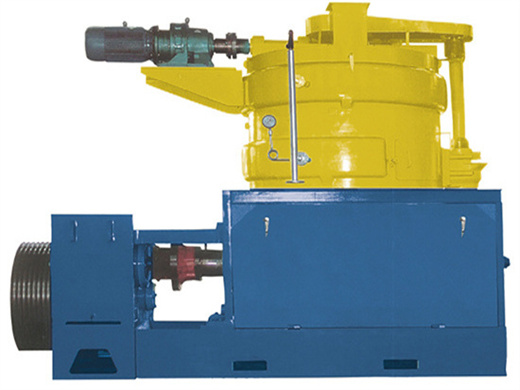

The Rice Bran Extraction Oil Extraction Machine Main Specification: 50~5000T/D. The Rice Bran Oil Extraction Machine/Plant Main Equipment: rotary multi cell extractor with stainless steel gate or drag chain extractor, D.T.D.C desolventizer-toaster, total negative pressure evaporator, paraffin recovery equipment, etc.

The miscella from the miscella holding tank enters the first evaporator, the second evaporator and the disk stripping column in the rice bran oil plant to separate solvent and crude rice bran oil. The solvent vapor enters the condensing system. The crude oil enters the crude oil holding tank. The rice bran oil extraction plant adopts negative

Solvent Extraction Plant Technology and Equipments

- Usage: Rice Bran Oil, Cooking Oil Production Capacity: 15 TONS /DAYVoltage: 50 hpDimension(L*W*H): 2640*1396*3403 MMWeight: 7000 KGWarranty of core components: 5 yearsCore Components: Motor, Bearing, GearboxOil type: Rice Bran OILExtraction of Oilseeds: Rice Bran OilMOTOR: 50 HPCAPACITY: 15 Tons/DayAfter Warranty Service: Spare partsCertification: ISO 9001-2008

The rice bran solvent extraction plant starts with raw material preparation. Rice bran is first screened. It is then heated by steam at temperature higher than 100 degrees Celsius to stop Lipase hydrolysis in rice bran prior to extraction. Rice bran oil can easily be obtained in direct solvent extraction of the rice bran.

Rice Bran Oil Extraction Process Oil Mill Plant

- Usage: Cooking Oil Type: Rice Bran Oil Extraction MachineProduction Capacity: 1tpdVoltage: 380V/50HZDimension(L*W*H): 2300*820*1420Weight: 1100 KGCore Components: Gear, Bearing, Engine, GearboxOil type: Rice Bran OilProcessing Capacity(t/24h): 9-11Motor Power(kw): 22Weight(kg): 1100Measurement(mm): 2300*820*1420Oil Content of Dry Cakes(%): ≤7.6Spiral Axes Rotate Speed(r/min): 30-40Quality: ISO CertificationBrand: GuangxinDelivery time: 20 - 25 Days

With rich experience and advanced rice bran oil mill machinery technology in this field, KMEC is your reliable rice bran oil plant manufacturer and supplier. The output rate of rice bran oil mill machinery is between 8-11% and the capacity is from 5t to 100t per day. We supply professional rice bran oil extraction process to all of our customers.

- How is rice bran oil extracted?

- 5. Solvent Extraction Process: Finally, the solvent extraction process begins. The oil from the rice bran pellets is dissolved in this phase using a solvent, usually hexane. After that, the oil and solvent are separated, leaving just pure rice bran oil remaining.

- How does rice bran oil refinery work?

- After cleaning, the rice bran is conditioned to prepare it for oil extraction. This involves adjusting the moisture content and temperature of the bran to achieve the ideal conditions for oil release. Proper conditioning enhances the efficiency of the rice bran oil refinery process by ensuring the bran is at its optimum state for extraction. 3.

- What is rice bran oil?

- Rice bran oil, known for its nutritional benefits and versatile applications, is derived from the outer layer of rice grains. The extraction of this valuable oil requires a meticulous process to ensure maximum yield and quality.

- What are the benefits of conditioned rice bran oil refinery?

- Proper conditioning enhances the efficiency of the rice bran oil refinery process by ensuring the bran is at its optimum state for extraction. 3. Palletization: The conditioned rice bran is compressed into pellets during the palletisation step. This step not only facilitates uniform solvent penetration during extraction but also minimizes wastage.

- What is conditioned rice bran?

- The conditioned rice bran is compressed into pellets during the palletisation step. This step not only facilitates uniform solvent penetration during extraction but also minimizes wastage. Rice bran oil output increases when bran is pelletised because it guarantees a more efficient and regulated extraction process. 4. Pellet Cooler:

- Why is there a gap between rice bran oil production and availability?

- The wide gap between the actual production and the potential availability of rice bran oil is primarily due to the fact that at present around 70 per cent of the paddy produced in the country is processed through huller mills while only 30 percent is processed by modern sheller mills.