Palm Oil Processing Machine Prices in Nigeria

- Usage: Palm OIL

- Production Capacity: 180kg/h

- Voltage: 380V/50HZ

- Dimension(L*W*H): 1890*1520*1915

- Weight: 1075 KG

- Warranty: 1 Year

- Key Selling Points: Energy saving

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Gear, Bearing, Engine, Gearbox

- Processing Capacity(t/24h): 4.5

- Motor Power(kw): 11

- Weight(kg): 1075

- Measurement(mm): 1890*1520*1915

- Oil Content of Dry Cakes(%): ≤7.8

- Spiral Axes Rotate Speed(r/min): 32-40

- Quality: ISO Certification

- Brand: Guangxin

- After-sales Service Provided: Field maintenance and repair service

- Delivery time: 20 - 25 Days

10 tons palm oil processing machine and palm oil refinery plant N905,000 N1.1 million; High-Efficiency Red Palm Oil Refining machine small scale crude vegetable seeds oil refinery equipment N617,100 N2 million; High-efficiency small scale palm oil refining machinery/edible oil refining machine N822,000 N1.3 million

Through our column, we will cover a wide range of topics ranging from the production process to quality control. Our team of experts will provide you with all the information you need to refine crude palm oil into a high-quality product that meets the dem

How to Choose Palm Oil Fractionation Machine and Process

- Usage: Palm Oil

- Type: edible oil solvent extraction machine, Palm oil cake manufacturers

- Production Capacity: 100%

- Voltage: Local Voltage

- Power(W): Capacity

- Dimension(L*W*H): 1200*400*900mm3

- Oil residue ratio: 0.5-1%

- Solvent consumption: ≤ 2Kg/T (No.6 solvent oil)

- Power consumption: ≤ 15KWh/T

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Residual oil in meal: ≤ 1% (Palm)

- Crude oil moisture and volatile matter: ≤ 0.30%

- Finished meal moisture: ≤ 13% (adjustable)

- Price: Competitive

- Quality: Top Level

Palm oil fractionation is to separate palm oil into low melting point liquid phase (soft fat) and high melting point solid phase (stearin) by control the cooling and crystallizing process. Finally, the palm oil can be divided into 3 components: Palm Stearin (melting point around 50℃): Suitable for making margarine and shortening.

Supply BEST Palm Oil Processing Plant Oil palm is now the most important supplier of vegetable oil in the world. QIYI Machinery can offer you the BEST customized palm oil processing solutions for both fresh fruit bunch and palm kernel/nut.

Buy Premium Palm Kernel Oil Processing Machine in Malaysia

- Usage: Palm Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 380V

- Dimension(L*W*H): 2400*1600*2600mm

- Weight: 1200 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Other, Gear, Bearing, Engine, Gearbox

- Oil type: Palm Oil

- Function: Making Edible Oil

- Feature: High Efficiency Low Cost

- Material: Stainess Steel

- Capacity: 3.4t/24h

- Quality: High Level

- Method to press: Screw Squeezed Press

- Character: High Effiency

- MOQ: 1 Set

It should not be confused with the other two edible oils derived from palm fruits: Palm oil, extracted from the kernel of the Palm, and palm oil, extracted from the pulp of the oil palm fruit. Palm Kernel Oil Processing Machine. Palm kernel oil processing machine is one of the most important equipments in palm kernel oil processing. Our.

Palm kernel cakes are widely used as animal feed for cattle for fattening and supplementary feeding due to its high protein content. It can also be used as a source of biomass to fuel up boilers for generating electricity. (Related Post: Cost of Palm Oil Processing Machine >>) Palm Oil Production Equipment for Palm Oil Milling Business

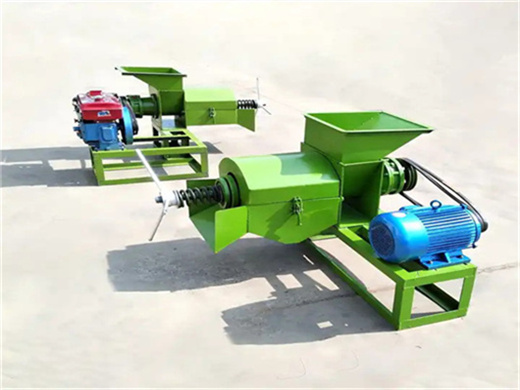

Buy Factory Price Small Scale Palm Oil Making Machine

- Usage: Palm Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 50-1000kg/h

- Voltage: 380v

- Dimension(L*W*H): 200*20*8m

- Weight: 50 KG

- Warranty: 3 years

- Warranty of core components: 3 years

- Core Components: Gearbox

- Oil type: Palm Oil

- Capacity: 200 tons per day

- Keep working: 24 Hours

- Used for: Pressed Vegetable Oil

Customized Small Scale Palm Oil Milling Machine. Since many Africa customers, especially in Ghana, Nigeria, and other countries, requires relatively small scale palm oil making machine. But, most of the Palm Oil Machinery Manufacturers can't supply the palm oil processing machine with such small scale capacity. So, it is not easy for small.

Highly Efficient Palm Kernel Oil (PKO) Processing Machines at

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, solvent extractor in oil

- Production Capacity: 30TPD-1000TPD

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Color: Silver

- Production Material: Carbon steel, stainless steel

- Raw material: Palm

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical operating

- Warranty period: One year

- Factory visiting: Yes

Both of the two palm kernel oil processing requires relatively large investment and complicated oil processing technology. Large Palm Kernel Oil Processing Machine and Plant. The extract cost for palm kernel oil processing plant is decided by many factors. If you are truly interested in palm kernel oil processing machinery, whether it is in.

- How do palm oil processing machines work?

- Palm oil processing machines 1. Fruit Reception: It is used for temporary storage and unloading fresh palm fruit bunches from palm plantation. Fruit reception 2. Sterilizer: three types of sterilizers can be chosen in palm oil processing. All use high temperature of 145°C to soften and sterilize the fruit bunches.

- What is a palm oil press machine?

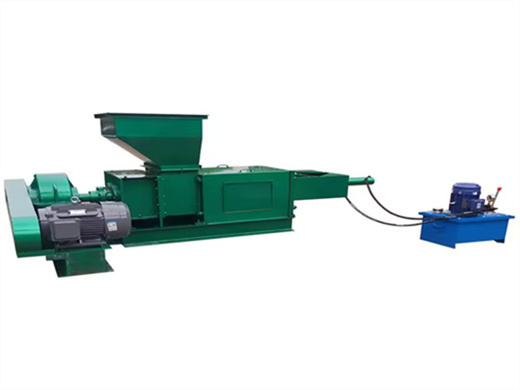

- Palm Oil Press Station: Separate palm fruit and kernel, and Palm Oil Press Machine can obtain CPO (crude palm oil) and palm kernel oil. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil processing.

- What is Huatai palm machinery?

- Huatai palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of palm oil production business.

- How is palm oil produced in Indonesia?

- Currently, the dominant palm oil production processes in Indonesia are modern, and these large mills typically employ continuous sterilization, threshing, and pressing processes to extract oil from the palm fruit bunches (As noted earlier).

- What is palm oil production process?

- The complete palm oil production process consists of three main parts: palm oil pressing, refining and fractionation. (Of course, you can contact ABC Machinery for customized unique process design for your palm oil mill business.) Oil palm fruit bunches → Sterilizing → Threshing → Digesting → Screw/Hydraulic pressing → Filtration → Crude palm oil

- What machines are used for palm oil processing?

- Below is mainly about the machines used for complete palm oil processing, including sterilizing tanks, thresher, digesting tanks, screw oil presses, vibrating screen, oil clarification tank and plate and frame filter and so on. Palm oil processing machines 1.