Palm Biomass Waste Pellet Production Pellet Making Machines

- Usage: Palm Oil

- Production Capacity: High

- Voltage: 380V/50HZ

- Dimension(L*W*H): 2900*1850*3640 mm

- Weight: 5500 KG

- Warranty: 1 Year, Long Term Technical Support

- Key Selling Points: Multifunctional

- Marketing Type: Ordinary Product

- Machinery Test Report: Not Available

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Other

- After-sales Service Provided: Engineers available to service machinery overseas

- Advantage: Final are more flavor and pure

- Color: Different accoding to requirement

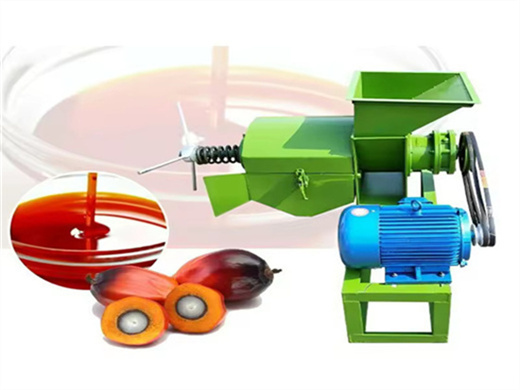

- Raw material: Palm Kernel

- Function: Making Palm Oil

- Application: Palm Oil Production Line

- Product name: Screw Press Oil Expelle

- Material: Stainess Steel/Carbon Steel

While being burned, the biomass pellets from oil palm wastes do not generate sulfur dioxide nor phosphoric anhydride since they do not contain phosphorus or sulfur. Due to this, oil palm pellets do not pollute the atmosphere nor pollute the environment. The biomass pellets made from oil palm wastes are easy to transport, handle, and store.

The pelletization process turns shredded EFB fibre into EFB pellet, allowing it to become drier to be a reliable biofuel resource. Below is the basic specification for EFB pellet. Malaysia is one of the world’s largest producers of palm oil and shredded EFB is an unavoidable by-product of the oil palm industry.

2020 Analysis Of The Malaysia EFB Pellet Market

- Usage: Palm oil

- Type: Palm Oil Press Machine

- Production Capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Power(W): Capacity

- Dimension(L*W*H): Palm Oil Press Machine Acorrding to your request

- Weight: Palm Oil Press Machine Acorrding to your request

- Processing: Batch-type or Semi-continuous

- Electric Consumption: 28Kwh/T Oil

- Soften Water:

- Phosphoric Acid:

- Bleaching Earth Consumption:

- Refining Rate:

- Waste Bleaching Earth Oil Content:

- Circulating Water Cooling Water Yield:

- Supplier Type:

- ITEM: Palm Oil Press Machine

Therefore, the skill of making EFB pellets is rather mature in Malaysia. There are six types of oil palm biomass, which can be produced to biomass pellets: oil palm fronds (OPF), oil palm trunks (OPT), empty fruit bunches (EFB), palm kernel shells (PKS), mesocarp fibre (MF) and oil palm mill effluent.

From Palm EFB and Palm Fibre into Palm EFB Pellets. Malaysia is well know palm agriculture, and shredded EFB fibre is the by-product for the industry. Converting shredded EFB fiber becoming EFB pellet is a major contribution in renewable energy. EFB Pellet is the product manufactured from shredded EFB fibre.

OWN Biomass flat die pellet press machine for homemade use now!

- Usage: Palm Oil

- Type: Continuous & semi-continuous refining

- Production Capacity: 90%

- Voltage: 220V/380V

- Dimension(L*W*H): 4150*900*2300mm

- Weight: 1400 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, Other, Gear

- Product name: crude red palm oil refining machine

- Raw material: Palm Kernel

- Function: Oil refining

- MOQ: 1 Set

- Package: Wooden Case

- Application: Food Industry

- Operation: 1-2 Person

- Capacity: 1-10t/d

GEMCO is a member of China Association Of Rural Energy Industry(CAREI), as well as the standard maker of China Flat die biomass briquetting technology. GEMCO has obtained the ISO9001 international quality system certification and EU CE Certification, with more than 80% products exported overseas.

RICHI palm fiber pellet machine is a pelletizing equipment for processing palm tree waste and palm oil factory waste such as pam fibers, palm nut shell, palm kernel shell, empty fruit bunch, palm leaf, etc. For different types of palm waste raw materials, RICHI will design a complete set of efb pellet plant and PKS pellet plant process of 1-100t/h for customers, and provide a single palm.

PKS Pellets-A Good Choice of Biofuel Pellets Investment

- Usage: Palm oil

- Production Capacity: 150-300kg/h

- Voltage: 220v/380v/Customer request

- Dimension(L*W*H): 1900*1400*1700mm

- Weight: 1100 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Marketing Type: Hot sale 2022

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Raw material: Palm Kernel

- Function: Oil Pressing

- Operation: Automatic Operate

- Advantage: Energy Saving Low Residual

- Oil rate: Meal Residual: 1%

- Capacity: Large

- Material: Stainess Steel

- Processing Types: Screw Pressing

- Keep working: 24 Hours

Because of the residue palm oil, the heating value of palm kernel shells is slightly higher than the lignocellulosic biomass. The palm kernel shell is widely existed in Malaysia, Indonesia, Thailand,Japan, Korea and some Europe countries.

1.5 Ton Per Hour Palm Fiber Pellet Plant in Malaysia

- Usage: Palm oil

- Type: For automatic oil extruder machine for Palm gern usage

- Production Capacity: 10-3000 ton

- Voltage: 380v 440v

- Power(W): As automatic oil extruder machine for Palm output every day

- Dimension(L*W*H): As automatic oil extruder machine capacity

- Weight: Depend on automatic oil extruder machine capacity

- Item: automatic oil extruder machine

- Material: Stainless steel

- Rate of Palm oil extraction: 30-48%

- Process of making Palm oil: pretreatment , solvent extraction ,refinery

- Embryo of Palm: 12%

- Endosperm of Palm: 82%

- Oil rate of press Palm: 65%

- Oil residual after pressed: 7%

- Shipping: by sea

- Payment: L/c ,T/T

This is a 1 ton palm fiber pellet plant for making EFB pellets. This pelletizing project is located in Malaysia. Make Palm Fiber Pellets. Palm Fiber & EFB Pellets. Palm Fiber Pellet Plant. This is the photos of gemco palm fiver pellet plant project. The capacity is 1 ton per hour. This pellet plant can also deal with many other biomass materials.

- What is Primera EFB pellet?

- Primera EFB pellets are suitable for most boiler grinding systems and is easy for operation and storage due to its size. Palm Kernel Shell (PKS) is a layer that protects the oil palm kernel. It is the shell fractions left after the nut has been removed after crushing in the palm oil mill. PKS has an estimated small diameter of around 10mm.

- Why should you invest in biomass in Malaysia?

- Malaysia has become one of the most exciting destinations for biomass-based investments in the region with numerous technical/strategic-level visits by reputable international investors and technology partners to explore investment opportunities in renewable power generation, bio- pellets, 2nd generation advanced biofuels and biochemical products.

- Is PKS a good biomass fuel?

- PKS is a good quality biomass fuel with uniform size distribution, easy handling and easy crushing. As a raw material for biomass briquettes or pellets, PKS have similar calorific characteristics as coconut shells.

- Can PKS be used as a biomass briquette?

- As a raw material for biomass briquettes or pellets, PKS have similar calorific characteristics as coconut shells. However, its smaller size makes it easier to process for mass production and its resulting coal can be pressed into a heat efficient biomass briquettes or pellets.

- What is palm kernel expeller (PKE)?

- Palm Kernel Expeller (PKE) or Palm Kernel Cake (PKC) is a by-product of the palm oil extraction process from the fruit of the oil palm. It is a quality stock feed containing high levels of crude protein and moderate energy levels.