Palm Oil Production Line, Palm Oil Processing Machine, Palm Oil Refinery Machine

- Usage: Palm Oil, cocoabean oil

- Type: Oil Extraction Machine

- Production Capacity: 80-800kg/h

- Voltage: 220V/110V

- Dimension(L*W*H): 460*230*260(mm)

- Weight: 100kg

- Core Components: Pressure vessel

- Oil type: Palm Oil

- Advantage: Simple Operation

- Application: Family

- Trade Item: FOB

- Delivery: 7-10 Days

- Material: 304 Stainless Steel

- Feature: Automatic

- Shipping: By sea/air

- Keep working: 8-24h

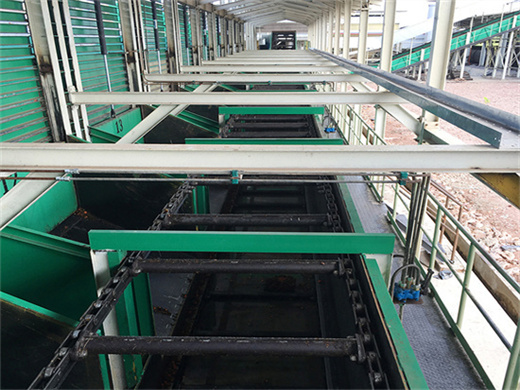

Complete Palm Oil Production Line. Our Oil Machinery can provide large scale complete Palm Oil Production Line solutions with 5-120TPH capacity. Palm Fruit Pretreatment and Oil Press: 1. Palm Fruit Reception: Firstly, transport FFB to reception station, flow to the scraper conveyer, conveyed to sterilizing station. 2.

Sterilization as the first step in palm fruit pressing is critical to the quality of the final production palm oil. The purpose of sterilization process is, inactivate the activity of lipase and prevent the rise of free fatty acids; make the palm fruit easier to fall off from the fruit bunch; and soften the peel and make the oil easier to separate out.

The customer in Abidjan, Cote d 'Ivoire purchased a set

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, hot oil press machine

- Production Capacity: 98%-100%

- Voltage: 380

- Power(W): 7.5kw

- Dimension(L*W*H): 1700*1300*1750mm

- Weight: 780kg

- Capacity: 80-1500 kg/h

- Material: Stainless Steel SS304/316

- Residual oil rate: 6~7%

- Raw material: Palm

- Advantage: 36 Years for oil press machine

- Warranty period: 12 Months

- Application: Oil Pressing

- Oil standard from it: high purity crude oi

A Ivory Coast customer successfully ordered 0.5tph single screw palm oil press machine from Henan Glory company. A Ugandan client successfully ordered 3TPH palm oil production line, 2TPH palm kernel cracking and separating machine and 0.5TPH palm kernel oil production line from Henan Glory Company

Palm Oil Machine. High quality high oil yield and design of Palm Oil Production Line is the key to success of palm oil plant business. Our Oil Machinery is leading professional manufacture and supplier of palm oil production line equipment includes palm fruit oil press and palm kernel oil extraction, CPO Refinery, and palm oil fractionation.

Palm kernel oil extraction machine, Palm Oil Production Line

- Usage: Palm Oil

- Production Capacity: 98%-100%

- Voltage: 320W

- Dimension(L*W*H): 49*25*45cm

- Weight: 8 KG

- Warranty: 6 Months

- Key Selling Points: Long Service Life

- Machinery Test Report: Provided

- Video outgoing-inspection: Not Available

- Warranty of core components: 6 Months

- Core Components: Spare parts

- Raw material: Palm Kernel

- capacity: 2.5~3kg

- style: automatic

- panel: english panel

Basic Unit Operations of Palm Kernel Oil Extraction Processing: · Palm Kernel Pre-treatment; · Oil Extraction; · Solvent Recovery From Oil and Meal; The following is the main advantages of palm kernel oil extraction machine and plant: 1. Fit for mass production of Palm Kernel Oil Extraction Machine; 2.

If the capacity of your palm fruit oil processing machine is about 1-5 tons/hour, you can choose the standard configuration of palm oil production line equipment, mainly by the fermentation tank, fruit extractor, mashing tank, palm oil press, rotary sieve and plate and frame filter and other equipment, the investment is generally from hundreds of thousands to millions, mostly suitable for.

Palm Oil Pressing Process Introduction Palm Oil Production Line Palm Oil Refinery Machine

- Usage: Palm Oil

- Production Capacity: 100%

- Voltage: 380V

- Dimension(L*W*H): 3806*1238*3418

- Weight: 8500 KG

- Warranty: 1 Year

- Key Selling Points: High Productivity

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing, Engine, Gearbox, Motor

- Capacity: 35-50TPD

- Raw material: Palm Kernel

- Color: can be customized

- net weight: 8500

- dimension: 3806*1238*3418

- Residue oil in the cake: 4-6%

- Pressing type: pressing

- Quality: Best

The main products of the palm fruit crushing plant are crude palm oil and palm kernels, and the processing capacity is about 60~100 tons of palm fruit bunches per hour. For crude palm oil, the general to sterilization, threshing, cooking, pressing, washing, purification, drying and other processes.

China leading palm oil processing machine manufacture

- Usage: Palm Oil

- Type: Oil Extraction Machine

- Production Capacity: 3-500 kg/h

- Voltage: 220V, 220v/110v (50hz/60hz)

- Dimension(L*W*H): 45*18*28 cm

- Weight: 12kG

- Core Components: Motor

- Oil type: Palm Oil

- Material: 304 stainless steel

- Use for: Oil Press

- Warm-up time: : 10 mins

- Motor type: : commercial AC motor all steel hardened gear

HongDe Intelligent Equipment Group has obtained 9 national patents in palm oil equipment, including a vertical palm fruit sterilization tank (ZL 2016 2 0745156.7), a palm fruit shaftless drum thresher (ZL 2018 2 1627204.8), a palm fruit Oil production complete equipment (ZL 2019 2 0866343.4), palm oil sand removal brake device (ZL 2019 2.

- How to clarify palm oil?

- Clarifying & Drying: A mixture of oil, water, and solids from the bunch fibers is delivered to clarification station. It usually use vibrating screen, clarification tank and plate filter to remove the impurities from the crude palm oil, and use oil drying system to dry the crude palm oil.

- How does a palm oil press work?

- The main point of clarification is to separate the oil from its entrained impurities. The fluid coming out of the press is a mixture of palm oil, water, cell debris, fibrous material and ‘non-oily solids’. Because of the non-oily solids the mixture is very thick (viscous). Hot water is therefore added to the press output mixture to thin it.

- What is the process of oil palm pressing?

- The process of oil palm pressing including collecting, sterilizing, threshing, digesting, pressing, clarification and drying.

- How to extract Palm oil from palm pulp?

- Pressing: It can extract the palm oil from the palm pulp by pressing. After pressing, we can obtain crude palm oil containing impurities and water, and a mixture of fiber and palm nuts. Clarifying & Drying: A mixture of oil, water, and solids from the bunch fibers is delivered to clarification station.

- How is palm oil made?

- The screened mixture is boiled from one or two hours and then allowed to settle by gravity in the large tank so that the palm oil, being lighter than water, will separate and rise to the top. The clear oil is decanted into a reception tank. This clarified oil still contains traces of water and dirt.

- How does a palm oil drier work?

- Drying: Continuous Vacuum drier pumps water from crude palm oil. Palm oil moisture can reduces to as low as 0.1%. Continuous clarification tank clear lake containing oil enters into the oil tank, pump into centrifuge separation. The separated palm oil enters into circulating tank, and circulating pump sends it into oil clarification tank.