[Beginners Guide] How To Process Palm Oil

- Usage: Palm Oil

- Production Capacity: 10-2000T/D

- Voltage: Up to specification

- Power(W): Up to specification

- Dimension(L*W*H): Up to model

- Weight: Up to model

- Material of Machine: Carbon Steel,Stainless Steel

- Raw material: Palm

- Residual of Oil: 1% max

- Warranty Period: 12 monthes

- Service: 3D design and turnkey project

- Operation: Easy to operate

- Worker Quantity: 3-5 person per shift

- Machine Color: Red,Green,Yellow...

- Raw material: Palm

To process palm oil, begin by harvesting fresh palm fruit bunches and separating the fruit from the bunches. Then, sterilize the fruit, extract the oil by pressing or using a mechanical extraction method, and finally, refine the oil through processes such as clarification and purification to obtain high-quality palm oil.

If the capacity of your palm fruit oil processing machine is about 1-5 tons/hour, you can choose the standard configuration of palm oil production line equipment, mainly by the fermentation tank, fruit extractor, mashing tank, palm oil press, rotary sieve and plate and frame filter and other equipment, the investment is generally from hundreds of thousands to millions, mostly suitable for.

Palm Oil Industry—Processes, By-Product Treatment and Value

- Usage: Palm oil make machine price

- Type: Palm oil make machine price

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Power(W): 18.5KW/T

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- After-sales Service Provided: Overseas service center available

- Keywords: oil press machine

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: Palm oil make machine price

- oil rate: 20%-98%

2.1.3 Digestion and Pressing for Crude Palm Oil (CPO) Extraction. Digestion is a process of palm oil extraction by breaking down the fruits via steam-heating in a vertical cylindrical digester. Fruits are softened at 80?90 °C using a steam jacket or by direct live steam injection (Ahmed et al. 2015). Under high temperature and pressure, the.

The refining process is like giving it a spa treatment. Crude palm oil, as the name suggests, isn't perfect yet. It contains some things we don't want, like impurities and odors. That's where refining comes in. Hence, in the second stage of palm oil process, we discuss refinery process of crude palm oil. Refinery of Crude Palm Oil

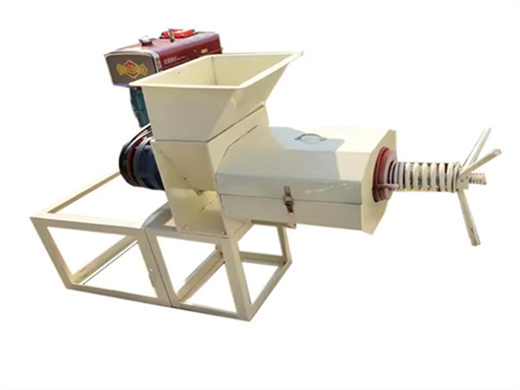

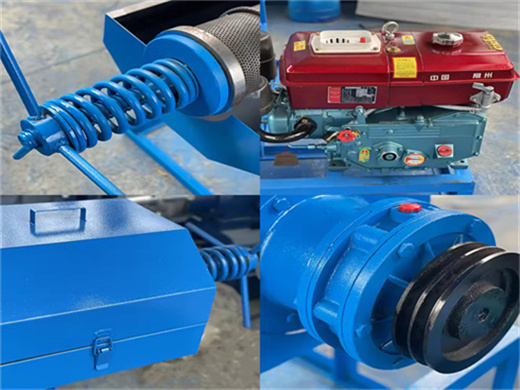

Screw Press Design for Palm Oil Extraction

- Usage: Palm Oil, Cooking Oil

- Production Capacity: 180-300 kg/h

- Voltage: 220V/380V/Customizable

- Dimension(L*W*H): 2150*1600*2700 mm

- Weight: 1600 kg, 1600 kg

- Core Components: Motor, Pump, Gear, Bearing, Gearbox, Squeezer

- Product Name: screw small oil pressers automatic Palm oil squeezing

- Capacity: 180-300 kg/h

- Vacuum Power: 1.1 kw

- Squeezer Speed: 60-100 r/min

- Dimension: 2150*1600*2700mm

- Color: Silver

- Advantage: High Productivity

- Grouped equipment: L-type feeding and vacuum filter system

The effectiveness of the screw press is very critical in optimizing the oil extraction. Ineffective press will result in high oil loss and maintenance cost of the machine. There are various types of screw presses used for the extraction of palm oil. The earliest was introduced to the palm oil industry in the early 1960’s.

Agricultural Engineering International: The CIGR Journal, 2020. The palm farmers of togo are suffering for want of an extraction machine. Therefore, a research was undertaken to design and develop a manually operated palm oil extraction machine at the department of Farm Power and Machinery, togo Agricultural University.

Traditional VS Mechanized Palm Kernel Oil Extraction Machine

- Usage: Palm OIL, Cooking Oil

- Type: Oil Press Machine

- Production Capacity: 50-800kg/h

- Voltage: 220V

- Dimension(L*W*H): 44x23x36 cm

- Weight: 13 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Oil type: Palm Oil

- Residual oil ratio: 1%

- Production capacity: 50-800kg/h

- Raw material can press: all kind s

- Tempreature: <=50

- color: Silver or other according to your need

The mechanical extraction process is suitable for palm kernel oil extraction with various processing volumes. The following mainly talks about the extraction method of palm kernel oil from pretreatment, pressing and filtration. Mechanical palm kernel oil extraction process. Mechanized palm kernel oil extraction begins with pretreatment.

Understanding the Intricate Palm Oil Production Process

- Usage: Palm oil production line

- Type: Palm oil production line

- Production Capacity: 20-200 TPD

- Voltage: 220V/380V

- Power(W): Accoding to your capacity

- Dimension(L*W*H): Accoding to your capacity

- Weight: Accoding to your capacity

- Item: Palm oil production line

- Supplier type: Manufacturer

- Manufacturing experience: 19 years

- Texture: Mild steel and SS

- Model type: Continuous

- Handling capacity: 20-200MT per 24hrs

- Materials: Palm

- Final product: Palm oil production line

- Service scope: Installation and debugging

The process of palm kernel oil extraction machine involves cracking and deshelling the palm seeds to obtain crude Palm Kernel Oil (PKO) and Palm Kernel Expeller (PKE). The PKO is then refined for use in food products such as non-dairy creams and ice cream, thanks to its unique properties and characteristics.

- How much palm oil does Togo export?

- Exports In 2021, Togo exported $45.8M in Palm Oil, making it the 37th largest exporter of Palm Oil in the world. At the same year, Palm Oil was the 15th most exported product in Togo. The main destination of Palm Oil exports from Togo are: Niger ($23.5M), Senegal ($10.7M), Ghana ($8.14M), Benin ($1.28M), and Burkina Faso ($1.17M).

- How is palm oil extracted?

- It begins with the cultivation and harvest of the fruit from mature trees anywhere between the ages of four and 30 years. After the preparation of the fruit, it is transferred to a palm oil extraction machine. The crude palm oil is eliminated of its impurities in a palm oil refinery plant.

- What are the steps in palm oil production?

- PALM FRUIT PREPARATION Step 1: inspection. When they arrive at a palm oil processing unit, the palm fruits are first inspected and subjected to quality assessments to ensure that only good quality fruit makes it to the palm oil production line. Step 2: sterilization.

- How does palm oil production process work?

- Step 1: inspection. When they arrive at a palm oil processing unit, the palm fruits are first inspected and subjected to quality assessments to ensure that only good quality fruit makes it to the palm oil production line. Step 2: sterilization. Then, the FFBs are sterilized, with high-pressure steam destroying bacteria and deactivating enzymes.

- How much palm oil is extracted per bunch?

- Sophisticated large-scale installations of palm oil production lines can achieve extraction rates as high as 24% palm oil per bunch. Often, such plants supply international palm oil refinery plants. Different palm oil processing units may differ in their levels of mechanization, materials transfer mechanisms, and scale.

- What is the difference between palm oil production and palm oil processing?

- Such palm oil processing units ordinarily supply crude oil to domestic markets. On the other hand, large-scale palm oil production lines, fitted with equipment for multiple stages of the process, typically handle anywhere between 3 and 60 tonnes of FFB per hour.