Extraction Processes of Virgin Coconut Oil

- Usage: Coconut oil

- Type: For Coconut embryo oil extracting machine usage

- Production Capacity: 10-3000 ton

- Voltage: 380v 440v

- Power(W): As Coconut embryo oil extracting machine output every day

- Dimension(L*W*H): As Coconut embryo oil extracting machine capacity

- Weight: Depend on Coconut embryo oil extracting machine capacity

- Item: Coconut embryo oil extracting machine

- Material: Stainless steel

- Rate of Coconut oil extraction: 30-48%

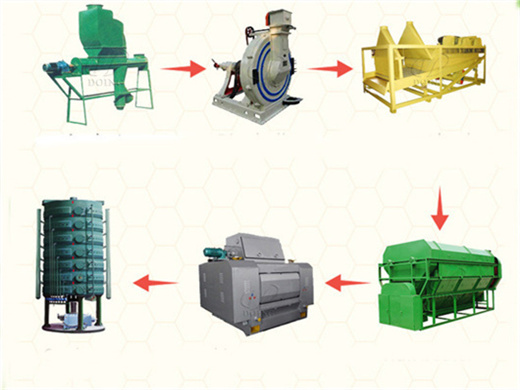

- Process of making Coconut oil: pretreatment , solvent extraction ,refinery

- Embryo of Coconut: 12%

- Endosperm of Coconut: 82%

- Oil rate of press Coconut: 65%

- Oil residual after pressed: 7%

- Shipping: by sea

- Payment: L/c ,T/T

Variety of coconut oils are available for edible purposes, mainly coconut oil from dried copra (unrefined grade), virgin coconut oil (VCO) from fresh kernel meat (unrefined grade), and refined

The conditioned flakes are pressed in the screw press where the oil is released. The cake with 18-20% oil will be send to the solvent extraction plant for further extraction leaving 1 1.2% of Oil. Method 2: Full Press 1 st Pressing

Snc Coconut Oil Extraction Machine Coconut Oil Refinery Plant

- Usage: Coconut Oil

- Type: Coconut Oil Machine Processing

- , Automatic

- Production Capacity: 100%, 5T-200T per hour

- Voltage: 380V/50HZ, 380V /440V or the local voltage

- Power(W): 15KW, According to the capacity

- Dimension(L*W*H): 1700*1100*1600mm, According to the capacity

- Weight: 1200kg, According to the capacity

- Supplier type: Factory(more than 35 years experience)

- Capacity: 5T-200T per hour

Snc Coconut Oil Extraction Machine Coconut Oil Refinery Plant in Botswana . Use: Coconut Oil; Type:Coconut Oil Extraction Machine; Production Capacity: 10T~50TPD; Power: : 800 W; Dimension(L*W*H): 1*1.1*1.66m; Voltage: 220V/380V/440V, 380-460V; Advantage: Oil Product Line; Market: Botswana

The daily capacity is processing 20 tons of copra (desiccated coconut) and get 10 tons of refined coconut oil. It is designed for manufacturing edible coconut oil from desiccated coconut (copra). Copra Oil Mill Plant Under Construction. The following photos were took during the project construction onsite.

The Extraction, Purification, and the Recent Applications of

- Usage: Coconut Oil

- Production Capacity: 1-1000TPD

- Voltage: 220V/380V

- Power(W): Depend onCoconut processing equipment capacity

- Dimension(L*W*H): Depend on Coconut processing equipment capacity

- Weight: Depend on Coconut processing equipment capacity

- Raw material: Coconut, Copra

- Process type: Coconut processing equipment

Coconut oil can be extracted through wet extraction and dry extraction methods. Coconut oil refining is usually carried out on dry extracted coconut oil and generally includes the bleaching

1) Virgin coconut oil is growing in popularity as a nutritional supplement and functional food. It has numerous health benefits supported by studies. 2) This paper focuses on designing a facility layout for efficient virgin coconut oil production. An effective layout can reduce costs by minimizing material handling and optimizing space utilization. 3) The objectives are to propose a layout

Small Coconut Oil Extraction Production Machine Starts

- Usage: Coconut fruit/Coconut, Coconut Oil making

- Type: Cold & Hot Pressing Machine, Coconut oil mill in malaysia

- Production Capacity: 5TPH

- Voltage: 220V/380V/440V

- Power(W): 10-35kw

- Dimension(L*W*H): 3000*5000*10000mm

- Weight: 5T

- Materials: Carbon steel Q235 and SS304

- Performance: Hight and stable

- Princple: Physical squeeze

- Who we are: Manufacture

- Impurity content of crude oil: ≤0.2%

- Motor: SIEMENS

- Finished product: Grade 1 cooking oil

Mechanical Coconut Oil Extraction Process: the dry coconut with 10% ~ 12% moisture is transported to the automatic scale to remove the broken iron through the magnetic chamber, and is ground into particles of about 0.3 cm in diameter, and the particles are pressed into a thin sheet to enlarge the surface of the dried coconut oil extracting.

Turnkey Virgin Coconut Oil Processing Plant installed in India

- Usage: whole cooking oil filtration equipment

- Type: cooking oil filtration equipment

- Production Capacity: 100%

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): various with capacity

- Weight: changed with capacity

- Raw material: Coconut, Copra

- Solvent name: n-hexane

- Capacity: from 5T to 2000T cooking oil filtration equipment

- Oil content in Coconut: from 18-22%

- Oil residues: less than 1%

- Function: getting edible oil and refining it

- Manufacturing experience: 19 years experience in edible oil field

- Material of equipment: stainless steel and carbon steel

This is a Fully Automatic Virgin Coconut Oil Processing Plant which is installed in India for our esteemed customer which includes equipment such as Coconut De-Husking Machine, Coconut De-Shelling Machine, Coconut Cutter, Hot Air Drier & Cooler, VCO Oil Expeller Machines, Conveyors, Oil Filter Press with Pump, Storage tanks, Control Panels, Spares, etc.

- What is virgin coconut oil?

- Virgin coconut oil is a new highly value added version of coconut oil in health food markets. Extraction of virgin coconut oil from coconut kernel is a major influential step for their commercialization. There are many extraction methods, among which cold and hot extraction are conventional extraction processes.

- What are the different types of coconut oil extraction methods?

- Moving beyond the cold pressing and hot extraction methods, there is the centrifugation technique. This method uses high-speed spinning to separate the oil from the other components of the coconut meat. Unlike other methods, centrifugation does not use heat, which means the quality of coconut oil is not compromised.

- How to extract coconut oil?

- Three diferent extraction techniques were used to extract coconut oil. Induced cold press, soxhlet, and supercritical fluid extraction (SFE). All extractions were conducted in triplicates and averages of the results were used. In the pressing process performed with the cold press device (GM-1000), small diameter 10 mm apparatus was used.

- Why is SFE extraction the best way to obtain coconut oil?

- Compliance with these standards is an indi-cator of the quality of the oil. Its shelf life is long, low degradability, and low rancidity. As a result, SFE extraction is the best method to obtain coconut oil in terms of yield, fatty acid content, and health.

- What is the process of coconut extraction using cold extraction techniques?

- Overall process of coconut extraction using cold extraction techniques Hot extraction process is an extraction process that involves heat. This heating step however will reduce the antioxidant properties of the coconut oil produced . Hot extraction process is a process in which heat is used to break the emulsion between water and oil molecules.

- What is solvent extraction in coconut oil production?

- Solvent extraction, a relatively modern practice in coconut oil production, leverages organic solvents to separate the oil from raw coconuts. Particularly, hexane is popularly used due to its efficiency and high oil yielding capacity.