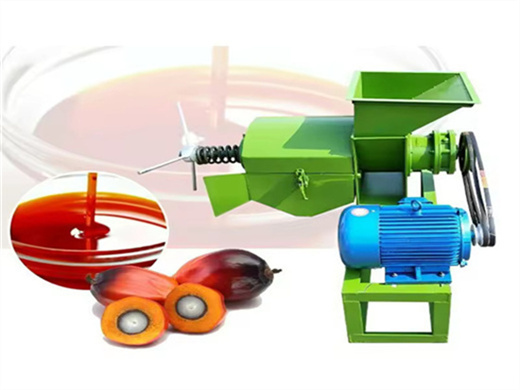

Design and construction of a palm kernel cracker and shell

- Usage: Palm Oil

- Production Capacity: 2kg/h

- Voltage: 220v/110v

- Dimension(L*W*H): 460* 180 * 310 mm

- Weight: 13.5 KG, 13.5 kg

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Bearing

- Power: 700 w

- Material: 304 stainless steel

- voltage: 220V / 110V

- Frequency: 50 HZ

- Size: 460* 180 * 310 mm

- Use: Domestic oil extractor

- Speed: 80 revolutions per minute

- productivity: 2kg/h

With the ever-evolving palm oil processing industry in Africa, the need for efficient and reliable palm kernel oil processing equipment is also promoting. In order to solve the problem of low efficiency for palm kernel cracking and kernel shell separating, Henan Glory Company has been updating the design and construction of palm kernel cracker.

Therefore, there are great demand of Palm Oil Extraction Machine and Palm Kernel Oil Extraction Machine in areas where oil palm is planted. Here, we will mainly introduce various models of mini small scale palm kernel oil extraction equipment to enhance the oil production efficiency. Mini Small Scale Kernel Oil Extraction Machine

Palm Kernel Oil Solvent Extraction Plant,Extraction Machine

- Usage: Palm Oil

- Type: Palm fruit oil making machinery, Palm oil press for sale

- Production Capacity: 1tpd-30tpd

- Voltage: Design according to customer demand

- Power(W): 11 KW

- Dimension(L*W*H): 4935*1523*2664

- Weight: Standard

- Production Material: Stainless steel or carbon steel

- Raw material: Palm

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical extruding

- Warranty period: One year

- Used for: Palm fruit oil making machinery

Solvent extraction plant is recommended for large palm kernel oil mill with high capacity. However, for small factories of palm kernel oil extraction, screw pressing plant is suggested. Basic Unit Operations of Solvent Extraction. Palm kernel pre-treatment; Oil extraction; Solvent Recovery from oil and meal; Solvent Extraction Station of Oil.

Palm kernel oil expeller. Step 6: Filter the crude palm kernel oil to get the clearer one. The pressed palm kernel oil should be filtered by plate filter, so that a clearer palm kernel oil can be obtained, and the quality of palm kernel oil also be better. The following is the operation video of palm kernel oil production line:

Traditional VS Mechanized Palm Kernel Oil Extraction Machine

- Usage: Palm Oil

- Type: Automatic Palm Fruit Oil Processing Machine

- Production Capacity: 60%

- Voltage: 220V/380v/customized

- Dimension(L*W*H): 800*1200*1300mm

- Weight: 260 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, PLC, Other

- Raw material: Palm Kernel

- Capacity: 60-70kg/h

- Package: Wooden Case Package

- Application: Palm

- Color: Customers' Requirements

- Method to press: Screw Squeezed Press

- Function: make cruder oil

- Processing Types: Screw Pressing

Advantages of using mechanized palm kernel oil extraction method: Palm kernel oil extraction methods. 1. The use of machine production greatly reduces labor costs and has higher production efficiency. 2. The degree of automation of mechanized production is high, and the oil yield of palm kernel oil is higher.

The followings are two challenges for setting up a complete palm kernel oil extraction plant: Complete palm kernel oil extraction plant is capital oriented business, so both the design of palm kernel oil plant and the extraction machine of palm oil will take up a large part of the business investment. Full scale palm kernel oil extraction.

Advanced Palm Kernel Oil Extraction Plant |Palm Kernel Seed Oil Processing Machine

- Usage: Palm oil extraction equipment

- Type: Palm oil extraction equipment

- Production Capacity: 1-2000TPD

- Voltage: 220V/380V/440V

- Power(W): 7.5kw

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- Application: Palm oil extraction equipment

- Raw material: Palm

- Material: Stainless Steel 304

- Function: Palm oil extraction equipment

- Character: Palm oil extraction equipment

- Warranty: 2 Years

- Feature: Feeding Automatically

- Quality: Top Level

- Wearing parts: Squeeze Spiral

While initial setup costs can be significant, solvent extraction plants can be economically viable in the long run due to their high efficiency and yield.( Palm kernel solvent extraction plants,Solvent extraction of palms kernel oil,Palm kernels oil extraction process,Palm kernel oil production plants,Hexane solvent extraction plants, Palm.

5. PALM KERNEL OIL EXTRACTION Food and Agriculture Organization

- Usage: Palm OIL

- Production Capacity: 50%-55%

- Voltage: 220V/110V

- Dimension(L*W*H): 58*29*36CM

- Weight: 13 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Marketing Type: Other

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Gear

- Application: Family

- Color: Silver

- Used for: Oil Processing

- Advantage: easy move and control

- After-sales Service Provided: Online Technical Support

- Raw material: Palm Kernel

- Function: Oil Mill Making Pressing Extracting Machine

- Material: SUS304

5.3 Traditional method of palm kernel extraction. Palm kernel extraction is a specialised operation undertaken by a completely different set of processors. They are usually better organized as a group and are not as dispersed as palm oil processors. The kernel processors have to go around the palm oil processors during the peak season, when.

- Who makes palm kernel oil extraction & refinery machine?

- Built by ABC Machinery - your best choice of palm kernel oil extraction & refinery machine manufacturer. If you are interested in starting your own palm kernel oil processing business, you can take this project report for reference. Get more about the equipment layout and factory design by the photo display below.

- How to set up a palm oil processing plant in Nigeria?

- There are many requirements for setting up a palm oil processing plant in nigeria which demands a feasibility study. These requirements include machines, available market, equipment, and labor. The project of setting up the plant should be technically, financially and environmentally feasible.

- Who is the best palm oil mill plant supplier in Nigeria?

- ABC Machinery, the top-rated palm oil mill plant supplier in China, has gained rich experience to provide the BEST palm oil processing machines in Nigeria. We boasts professional design and development team to customize the advanced palm oil processing machines and techniques for our Nigeria customers.

- How is palm oil extracted in Nigeria?

- The large scale processors attached to the estate mills offer high yields of 75% oil extracted of the available oil (PIND, 2011). However, more than 75% of the crude palm oil produced in Nigeria is still obtained thanks to traditional methods. SPO and PKO are the main inputs for secondary processing.

- What is the impact of palm oil processing mill in Nigeria?

- There were three main factors that had great impact on the development of palm oil processing mill in Nigeria: Traditional and out-of-date palm oil processing machines and techniques. As a result, Nigeria is no longer the leader of palm oil production in the world. It has been outpaced by Indonesia and Malaysia.

- How to sell palm kernel oil in Nigeria?

- To sell palm kernel oil in Nigeria, you must first register a limited liability company with the Corporate Affairs Commission of Nigeria and then register your business with the Nigerian Export Promotion Council and any local associations regulating the purchase and sale of Palm Kernel Oil (PKO).