Palm Kernel Oil Expeller Manufacturers and Exporters in indonesia

- Usage: Palm oil

- Production Capacity: More than 95%

- Voltage: 220V

- Dimension(L*W*H): 71*58*57cm

- Weight: 52 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Machinery Test Report: Not Available

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, PLC, Gearbox

- Product: centrifugal oil filter

- Control mode: full automatic

- Production: 30-50 kg/h

- Power: 500 W

- Material: stainless steel & glass

- Advantage: stainless steel material, oil & water separate

- Use for: Rap seed oil,Palm meat oil, Palm meat oil

- Package: Plywood package

Palm Kernel Oil % in Cake. 12-14% Oil Present in Cake after 1st Pressing. Less than 7% oil present in Cake after 2nd Pressing; Are you looking for the most suitable and cost effective palm kernel oil expeller machine or complete palm kernel oil production line to start your own oil manufacturing business, then you are in the right place.

Palm Kernel Expeller (PKE) is a vital by-product derived from the palm oil extraction process, renowned for its rich nutritional composition and multifaceted industrial applications. This article delves into the production methods, nutritional benefits, diverse industrial uses, sustainability considerations, and global significance of Palm Kernel Expeller, highlighting its pivotal role in.

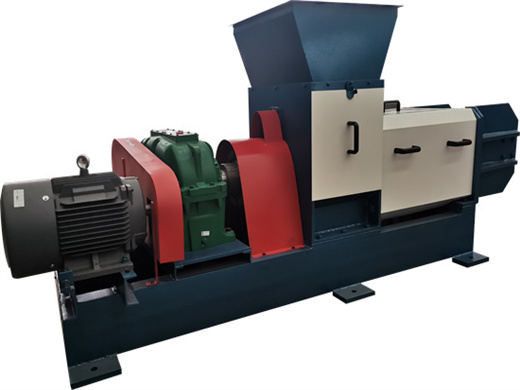

Oil Expeller, Vegetable Oil Extraction Plant Manufacturers

- Usage: Palm Oil

- Production Capacity: 100%

- Voltage: 380V

- Dimension(L*W*H): 2000*1300*1850MM

- Weight: 1250 KG, 1250KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Marketing Type: Ordinary Product

- Machinery Test Report: Not Available

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Other

- Application: Oil Production Line

- Item: Industrial Oil Extractor

- Function: Making Palm Oil

- Advantage: High Oil Yield

- Raw material: Palm Kernel

- Material: Stainless Steel/Carbon Steel

- After-sales Service Provided: Field installation, commissioning and training

Oil Expeller / Oil Press G 150; Oil Expeller / Oil Press G MK-IV; Oil Expeller / Oil Press G MK-V-C; Oil Expeller / Oil Press G 240; Oil Expeller / Oil Press G 600; Oil Expeller / Oil Press G 1500; Oil Expeller / Oil Press G 2400; Oil Expeller / Oil Press Palm Kernel; Palm Extruder; Seed Preparatory Equipments.

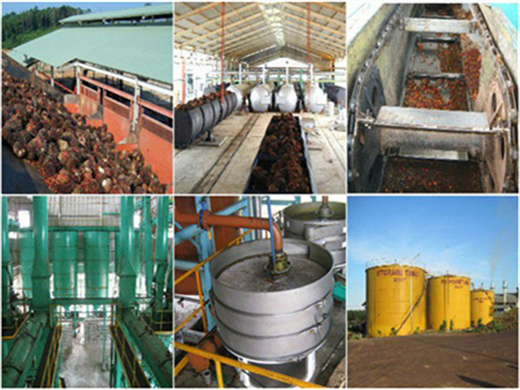

The kernels are centrifugally cracked in a drum machine and milled. The residue left after oil extraction from palm kernels is Palm Kernel Expeller (PKE). Palm Kernal Expeller is a good animal feed.It can also be used as a biofuel in certain cases. Palm Kernel Expeller is a brown powder, mostly with 1-5 mm size of the particles.

Sheanut Oil Manufacturing Process Flowchart Oil Expeller and Oil Refinery Machine

- Usage: Palm Oil

- Production Capacity: 100% Palm oil extractor processing equipment

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity

- Weight: Depand on your capacity

- Raw material: Palm

- Application: Palm oil Pressing

- Common capacity: 1-2000TPD

- Character: semi-auto, automatic

- Certificate: CE/BV/ISO9001

- Advantage: energy saving/high oil yield

- Flowchat: cold press/hot press/prepress

Groundnut Oil Manufacturing Process Flowchart; Palm Kernel Oil Manufacturing Process Flowchart; Palm Oil Manufacturing Process Flowchart; Palm Oil Manufacturing Process Flowchart; Jatropha Oil Manufacturing Process Flowchart; Sesame Oil Manufacturing Process Flowchart; Mustard Oil Manufacturing Process Flowchart

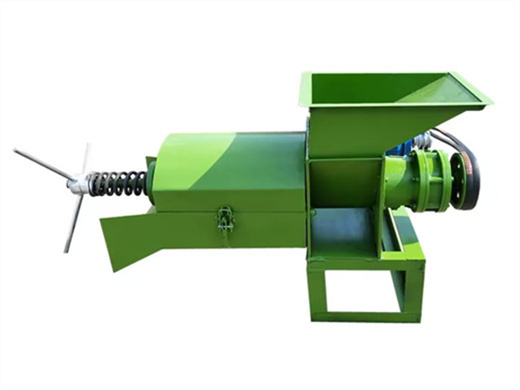

Design and Fabrication of a Palm Kernel Oil Expeller Machine Patrick Ejebheare 1Amiolemhen, JoshuaAhuromeEseigbe2 1,2Faculty of Engineering, Production Engineering Department, University of Benin, P.M.B 1154, Benin City, Nigeria. Abstract The aim of this work is to design and fabricate an effective palm kernel oil expeller machine.

Design and Fabrication of a Palm Kernel Oil Expeller Machine

- Usage: Palm Oil

- Type: set of machine

- Production Capacity: 100%

- Voltage: 220V/380V, 220V/380V

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 1500 KG

- Warranty: 1 Year

- Key Selling Points: Famous brand PLC

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, Engine

- After-sales Service Provided: Engineers available to service machinery overseas

- Material: Carbon Steel/SS

- Function: Palm pretreatment and oil extraction

- Raw material: Palm Kernel

- Color: as you wish

- Advantage: Automatic as you require

- Company type: manufacturing and sales

- Years of factory: 60 years

- Service: full service,design to after-sales

tenera and dura varieties of palm kernel = 619N (Ezeoba et al, 2012); L = length of press barrel = 450mm; = number of screw pitches = 5, ω = angular

Palm Kernel & Other Oil Expeller Spare Parts

- Usage: Palm Oil

- Production Capacity: 50 TPD

- Voltage: 100 HP

- Dimension(L*W*H): 3505t1820t1981

- Weight: 12000 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 5 years

- Core Components: Motor, Gear, Bearing, Gearbox

- After-sales Service Provided: Engineers available to service machinery overseas

- Extraction of Oilseeds: Palm ,Palm,Maize ,Palm Kernel ,Palm

- MOTOR: 100 HP

- CAPACITY: 50 Tons/Day

We provide a large variety of Oil Expeller Spare Parts to our esteemed customers. This Spares for Expeller range is available as Cast Steel & Steel Fabricated Chamber, Main Gear, Intermediate Gear, Main V-Belt Pulley, Lining Bar, Cage Bar Holder, Main Shaft Pinion, Driving Pinion Shaft, Hopper, Spacer Box, Gear Box Pinion, Gear Box Bevel, Kettle Bevel Gear, Main V-Bult Pulley, Cage Bar.

- What is a palm kernel oil expeller machine?

- A high torque and low rotational speed palm kernel oil expeller machine was developed by introducing an adjustable choke mechanism that permits adjustment of the back pressure to regulate the thickness and dryness of the pressed cake passing through the clearance between the barrel and the screw shaft.

- What is the design and development of a palm kernel oil expelling machine?

- A. Conclusion The design and development of a palm kernel oil expelling machine encompass the construction of essential components such as the hopper, expelling chamber, and the careful selection of the shaft and gear motor, among other vital parts.

- How does a palm kernel oilcake work?

- The expelled kernel oil flows through the slots distributed over the barrel circumference. The oilcake leaves the extraction machine through an adjustable cone and is then delivered to the second pressing Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield.

- How does a palm kernel machine work?

- The machine design enables cold palm kernel seeds to be processed without pre-treatment, the breaking and cooking operation being performed by the action of the screw shaft within the barrel of the unit. The machine has a nominal input capacity of approximately 280kg/hr when driven by a 10hp Electric motor.

- How palm kernel oil is processed?

- Because of their high oil content, Palm kernels have to be subjected to 2 stage pressing for maximum oil yield. The residue from First Stage Press is then transferred to a second palm kernel oil expeller machine for final crushing. The Oil &foots collected from both the First & Second Stage Pressing is delivered to the crude oil Filtering section.

- Is palm kernel a Bio product?

- Palm kernel is an important bio product from oil palm mill/processing. Plant palm kernel constitutes about 45% - 48% by weight of oil in which properties and characteristics are quite different from palm oil rather resembles coconut oil (Gbasonuzo et al. 2012). The major fatty acid (lauric (C) accounts for about 48% of the fatty acid composition.