HYDRO PRESS INDUSTRIES Palm Oil Fractionation Membrane

- Usage: Palm OIL

- Production Capacity: 98%

- Voltage: 220V

- Dimension(L*W*H): :800*650*1100mm

- Weight: 530KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Local Service Location: None

- After-sales Service Provided: Free spare parts

- Raw material: Palm Kernel

- Function: Press Oil Seeds

- Application: Commercial

- Capacity: 4KG/time

- Advantage: Simple Operation and automatic

- Power: 4KW+1.5kw

- heat power: 1kw

- Temperature: 70-100degree

- type: vertical Hydraulic oil press machine

HYDRO PRESS INDUSTRIES Membrane filter press for palm oil application are specifically designed to get maximum output yield from Sterin and Olein Separati

Sourcing Guide for Palm Oil Filter Press: With hundreds of thousands of products to choose from and an ever growing product range, your industrial equipment needs are sure to be m

HYDRO PRESS INDUSTRIES Semi automatic Membrane filter press

- Usage: Palm oil

- Production Capacity: 50-500kg/h

- Voltage: 220V/380V/as your demand

- Dimension(L*W*H): 900*1000*1400mm

- Weight: 950 KG

- Core Components: Motor

- Oil type: Palm Oil

- Raw material: Palm

- Function: Oil Mill Making Pressing Extracting Machine

- Capacity: 50kg-1000kg/hour

- Feature: Multifunction High Efficient

- Processing Types: Hydraulic Pressing Cold Press

- Oil rate: Oil Yield 99%

- Power: 1.5kw

- Package: 900*1000*1400mm

- Material: Carbon Steel Stainless Steel

HYDRO PRESS INDUSTRIES Membrane filter press for palm oil application are specifically designed to get maximum output yield from Sterin and Olein Separati

Should you require additional information regarding our products and services, you can reach us at: Tel: +603 5569 3993 Fax: +603 5569 3131 [email protected]

How to Choose Palm Oil Fractionation Machine and Process

- Usage: Palm Oil

- Production Capacity: 5-100TPD

- Voltage: 230V-380V-430V

- Power(W): 40kw/h

- Dimension(L*W*H): 20m*16m*15m

- Weight: 30tons

- After-sales Service Provided: Overseas third-party support available

- Machine type: oil Palm refinery

- Machine application: Palm oil

- Operation time: 24hours

- Electrical control: PLC control

- Workers needed: 2-3persons

- Machine material: carbon steel or stainless steel

- Power consumption: 22KWH/T oil

- Steam consumption: less than 300kg/t oil

- Soft water consumption: about 160kg/h

- Warranty period: 1year

In recent decades, membrane filter press has been widely used in palm oil industry. The hardness of stearin by using membrane filter press is higher, and the yield of palm olein can reach 70% ~ 75%, while it is only 65% by other two filers. Solvent Fractionation of Palm Oil Yeild of Palm Olein: 80%

China Oil Filter Press wholesale Select 2025 high quality Oil Filter Press products in best price from certified Chinese Oil Filtration manufacturers, Oil Equipment suppliers, wholesalers and factory

Rekayasa Teknologi FIlter Press Berbasis "Flexible FIlter

- Usage: Palm Oil, Palm EDIBLE OIL

- Type: Oil Press Machine

- Production Capacity: 100 kg/h

- Voltage: 220 - 380 volt

- Dimension(L*W*H): 125*35*63 cm

- Weight: 180 KG

- Core Components: Motor, Bearing, Gearbox, motor driver

- Oil type: Palm Oil

- Thermostat: 600 Watt

- Gear Box: Helical Shaft Gear

- Energy Consumption: 2500 - 3500 Watt/Hour

- Motor Power: 2.2 kW

- Raw material: Stainless Steel

- Function: Making Edible Oil

- Application: Screw Oil Expeller

- Feature: High Oil Yield Efficiency

Kata kunci: filter media, flexible filter media, crude palm oil (CPO), filter press. I. Pendahuluan Crude palm oil (CPO) merupakan komoditi agro industri andalan Indonesia dengan jumlah ekspor

Civil PCL

- Usage: Palm oil milling plant

- Type: Palm oil milling plant

- Production Capacity: 5-100T/H

- Voltage: 220V/380V/440V

- Power(W): 100kw

- Dimension(L*W*H): Depend on the capacity

- Weight: Depend on the capacity

- Raw material: Palm

- Process type: Palm oil milling plant

- Water cosumption: ≤ 0.5 t/t material

- Power consumption: ≤ 15 kw*h/t material

- Steam consumption: ≤ 320 kg/t mateiral

- Manufacturing experience: mroe than 30 Years

- Advantage: Energy Saving

- Solvent consumption: ≤ 3 kg/t material

- Workshop name: Palm oil milling plant

- Service: Arrange engineers

As innovative solution providers our teams develop and employ a variety of techniques and approaches to add value to clients. Whether using drones to optimize sequencing of earthwork or building 3D models for constructability reviews, technology can increase environmental protection, accelerate schedules and decrease costs.

- What is a palm olein Power Pack?

- For more sustainable production methods, ANDRITZ’s innovative palm olein power pack (POPP) offers a way to save filter press hydraulic oil expenditure by up to 80%. The POPP enhances food safety by driving the hydraulic system with palm olein, a superior alternative to food-grade mineral hydraulic oil.

- How do olein filter presses work?

- The membrane plates are inflated with air, water, or oil to squeeze out the entrained olein. ANDRITZ filter presses have been developed with multiple safety features in the machine components, providing greater operating reliability and helping achieve good and consistent product quality with a high olein yield.

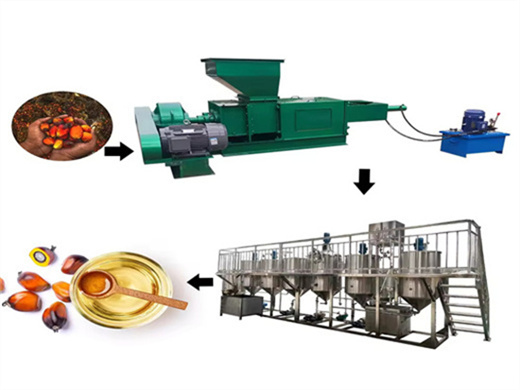

- What are the steps in palm oil production?

- Whatever the step in the palm oil production process—crude oil extraction, POME treatment, biogas sludge treatment, crude palm oil refining, or oleochemicals drying—a proper solid/liquid or oil/water separation phase is needed to meet the requirements of the final product.

- What is a palm oil mill effluent dewatering machine?

- For palm oil mill effluent (POME) dewatering from anaerobic ponds or digestate dewatering, palm oil millers are looking for low-energy and low-maintenance solutions. The ANDRITZ decanter centrifuge D is maintenance-friendly, with very competitive maintenance costs.

- Are Andritz filter presses safe?

- ANDRITZ filter presses have been developed with multiple safety features in the machine components, providing greater operating reliability and helping achieve good and consistent product quality with a high olein yield. In addition to a safe and reliable design with low operating costs, ANDRITZ filter presses are built with superior quality.

- How do I control the particle size of palm stearin?

- To precisely control the particle size of palm stearin, a spray congealer may be required. Depending on the desired particle size, various atomization methods such as a rotary atomizer, high-pressure nozzles, or a fountain nozzle can be employed.