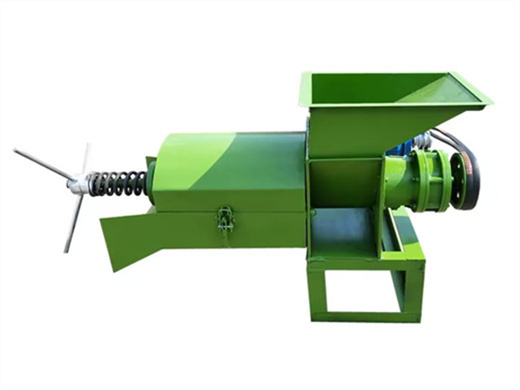

Palm Oil AOCS

- Usage: Palm Oil

- Voltage: 110/220V

- Dimension(L*W*H): 480*150*343mm

- Weight: 12 KG

- Core Components: PLC, Engine

- Oil type: Palm Oil

- Raw material: Palm

- Application: Food Industry

- Function: Making Edible Oil

- Feature: High Efficiency Low Cost

- Capacity: 1000ml

- Product name: Oli Press Machine

- Material: Stainess Steel

- Advantage: High Oil Yield

Introduction Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, whereby a mill commonly handles 60 to 100 mt per hour of FFB. The palm oil mill of today is based predominantly on concepts developed in the early 1950s (Mongana Report).

palm oil has been expanding rapidly since the late 1960s. In line with the increasing trend of output, world trade in palm oil more than doubled between 1969 and 1979. About 90 percent of palm oil exports go to markets in indus-trialized countries, but exports to new markets in developing countries have shown the most rapid growth.

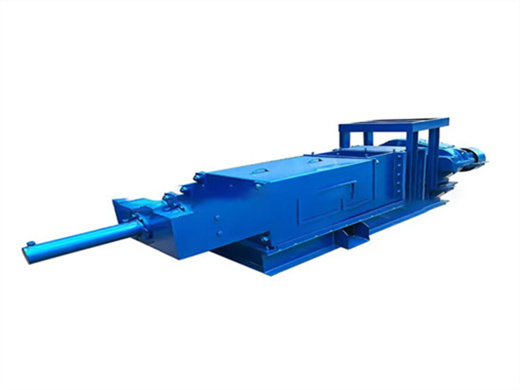

Palm oil

- Usage: Palm oil

- Production Capacity: 100%

- Voltage: 380V/50HZ

- Power(W): 15KW

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 1200kg

- Raw material: Palm

- Color: Oil Equipment Product Line as your requirment

- Material: carbon steel and stainess steel

- Application: Palm grinding machine

- Advantage: Oil Equipment Product Line

- Warranty: 12 month

- Feature: Palm extract/daidzein

- Character: Oil Equipment Product Line

- Use: Palm extract supplier

Palm oil is used to produce both methyl ester and hydrodeoxygenated biodiesel. [32] Palm oil methyl ester is created through a process called transesterification. Palm oil biodiesel is often blended with other fuels to create palm oil biodiesel blends. [33] Palm oil biodiesel meets the European EN 14214 standard for biodiesels. [32]

Palm oil has become one of the most valuable commodities in the global vegetable oil processing industry. The process of turning palm oil into Crude Palm Oil (CPO) involves a complex yet structured series of steps, transforming fresh palm fruit into crude oil ready for further processing. Let’s dive into each stage of this processing journey.

The Process Of Palm Oil Palm Oil Mill Machine Leading

- Usage: Palm Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 10-500ton/day

- Voltage: 220V380V

- Dimension(L*W*H): 1.2*0.78*1.1m

- Weight: 300 KG

- Core Components: Motor, Pressure vessel, PLC

- Oil type: Palm Oil

- item: Oil Press Machine With Filter

- Method to press: : Screw Squeezed Press

- Type: Cooking Oil Press Machine

- Raw material: Palm

- Application range: Crude Oil

- Function: Oil Mill Making Pressing Extracting Machine

- Oil cake diameter: : 192mm

- Advantage: High Oilput

- Product name: oil making machine

Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells. The digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a number of beater (stirring) arms.

Established in 1973, the Palm Oil Mill (POM) began with a small processing capacity. Over the years, it has undergone several expansions and now operates with a capacity of 60 metric tons per hour (mt/hr), producing Crude Palm Oil (CPO).

How Palm Oil Is Made In Factory Palm Harvesting

- Usage: Palm Oil

- Voltage: 380V/220V or as required

- Dimension(L*W*H): 2700*820*1400mm

- Weight: 1800 KG

- Warranty: 1 Year

- Key Selling Points: Energy saving

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: More than 5 years

- Core Components: Motor

- Function: Press Oil Seeds

- Application: Mini Palm Oil Mill Plant

- Advantage: Energy Saving Low Residual

- Capacity: 20t/d

- Material: Carbon Steel Stainless Steel

- Raw material: Palm Kernel

- Processing Types: Screw Pressing

- Used for: various dried oil seeds

- Quality: China Profesional Oil Press Machine

- Product name: Commercial Small Screw Palm Oil Press Machine

How do they make palm oil? In this video, I will show you the process of making palm oil. It is one of a short video in a series of short, concise videos tha

Palm Oil Mill Process for Starting Palm Oil Extraction Machine

- Usage: Palm oil edible oil refinery project

- Type: Palm oil ,cooking oil refinery

- Production Capacity: depend on requirement

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1500*680*1400mm

- Weight: Depend on capacity

- Core Components: Motor, Engine

- Capacity: depend on client's requirement

- Raw material: carbon steel and stainless steel

- Color: Clients' Requirements

- Advantage 1: simple operation

- Advantage 2: high output

- Advantage 3: small investment quick return

- Item: edible oil refinery project cost

- Application: 10-100TPD Palm oil refinery

- Function: Degumming,decoloration, deodorization

For further handling of palm oil,the palm oil refining procedure and palm oil fractionation process is necessary.The palm oil refining procedure can dispose of the destructive polluting influences and unnecessary substance in the unrefined consumable oil, getting standard palatable oil by using the physical techniques and compound procedures.

- How to extract Palm oil from fruit?

- This is the process of palm oil physical extracting (screw pressing) and field factors that determine quality of expelled palm oil. For extracting oil from palm fruits, you will have to start by harvesting fresh fruit bunches and keeping them ready for the next stage of palm oil production.

- How is palm oil made?

- It is derived from the fruit of oil palm trees and undergoes a fascinating production process that involves several stages. This page will guide you through the journey of palm oil, highlighting the key steps from the mill to the refinery and fractionation.

- Where does palm oil come from?

- The oil palm tree, scientifically known as Elaeis guineensis, is native to West Africa but has been extensively cultivated in Southeast Asia, Latin America, and other tropical regions due to its high oil yield. The palm oil industry relies on these plantations to meet the global demand for palm oil.

- What is the process of palm oil production?

- The process of palm oil production is a complex and intricate journey from fruit to oil. This comprehensive overview dives into the various stages involved, such as fruit harvesting, sterilization, threshing, oil extraction, clarification, and refining.

- What is palm oil winning process?

- The oil winning process, in summary, involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export.

- How do you process palm oil?

- Then, sterilize the fruit, extract the oil by pressing or using a mechanical extraction method, and finally, refine the oil through processes such as clarification and purification to obtain high-quality palm oil. Embarking on the journey of processing palm oil may seem challenging, but the rewards are undoubtedly worth the effort.