Record Palm Oil Production Forecast for C?te d Ivoire and Ghana

- Usage: Palm Oil, Cooking Oil

- Production Capacity: 500-1000kg/24H

- Voltage: 220/380v, 220/380 v

- Dimension(L*W*H): 1850*1050*1750mm

- Weight: 240 KG

- Core Components: Motor

- Oil type: Palm Oil

- Motor Power: 3kw

- Capacity: 500-1000kg/24H

- Application: Palm oil making machine

- usage: motor oil making machine

- Product name: date oil machine

- Heating Power: 1.1 kw

Figure 2. Palm oil production maps for C?te d’Ivoire and Ghana. Palm Oil Area Mapping for Small-scale Landholders and Large-scale Industrial Estates . USDA/FAS personnel visited major palm oil producing regions in C?te d’Ivoire from July 18 to 22, 2022, and Ghana from July 25 to 29, 2022 (Figure 3). The FAS survey team

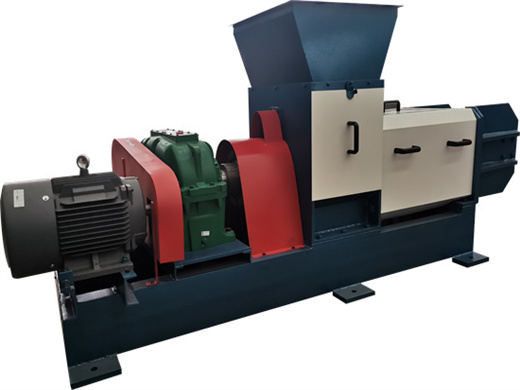

Prices of Palm Oil Processing Machines (by Production Process Steps) Due to the special characteristics of palm fruit structure, palm oil production process and equipment is more different from other oilseeds. (Palm kernel oil production process and the machines used are similar to general oilseeds.) Small Palm Oil Processing Production Line.

Palm oil processing plant business plan in Ghana

- Usage: Palm Oil

- Production Capacity: 500-7000kg/h

- Voltage: 220v

- Dimension(L*W*H): 46cm * 22cm * 26cm

- Weight: 8 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, PLC, Engine

- Product name: automatic oil press

- Function: Oil Production

- Raw material: Palm,ect

? Crude palm oil filter machine-vibrating screen+clarification machine+ plate filter machine Palm oil drying machine Palm oil tank. Palm oil processing machine of Henan Glory Company. The palm oil processing machine ‘s price in Henan Glory company is varied according to the scale of palm oil plant. The 1-5 tph palm oil production.

The above is palm oil press machine and production line, and these palm oil machines are popular in nigeria. Of course, our company also has palm oil refining machine and palm kernel processing machine. If you want to know more about palm machine information, such as palm oil production process, palm oil press, and palm oil production business.

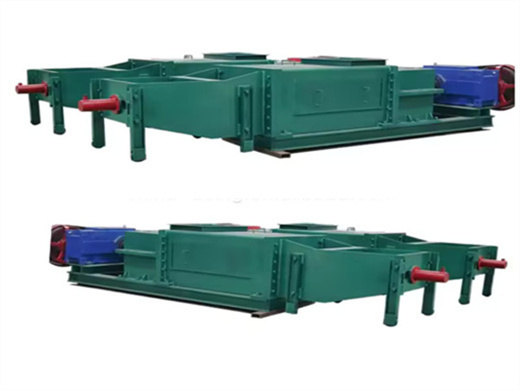

Palm Oil Mill Sterilizer Palm Oil Production Line

- Usage: Palm Oil

- Production Capacity: 100%

- Voltage: 380V/50HZ

- Power(W): 15KW

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 1200kg

- Raw material: Palm

- Color: Oil Equipment Product Line as your requirment

- Material: carbon steel and stainess steel

- Application: Palm peeling and press

- Advantage: Oil Equipment Product Line

- Warranty: 12 month

- Feature: press and extraction machine

- Character: our Palm pressing and extraction machine

- Use: press and extract Palm

sterilizer palm oil mill boiler villa-yasemin-tuerkei.de. Palm oil mill process_Manufacture Palm oil extraction . 2019-3-22 · 2. Palm oil mill process of sterilizer: Fresh palm fruit bunch are airtight sterilized in sterilizer, injecting direct steam (the pressure is 300KPa) to heat 60mins.

So, in order to improve the unfavorable condition of mini/small scale palm oil production, we design a new type of Small Scale Palm Oil Making Machine. It has many advantages for the Palm Oil Production Line, including reliable performance, simple operation, easy maintenance, high oil output, etc.. Hot-Sale Small Scale Palm Oil Machines Types

working principle of palm kernel cracker

- Usage: Palm Oil

- Voltage: 220V/110V, 220V/110V

- Dimension(L*W*H): 650*300*450mm, 650*300*450mm

- Weight: 20 KG

- Warranty: 1 Year

- Key Selling Points: Easy to Operate

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Product name: Small Oil Press Machine

- Production Capacity: 10kg/h

- Power: 1000w

- Function: Multifunction

- Application: Food Processing Units

- Keywords: Palm Powder Oil Press Machine

- Final product: Palm Oil

- After-sales Service Provided: Service Machinery Overseas

Till now, our palm kernel cracker and separating machine have exported to many countries, such as Nigeria, Ghana, Liberia, Sierra Leone, Cote d'Ivoire and so on. It is no exaggeration that we have rich experience in palm kernel cracker and separating machine installation, debugging and maintenance.

Sterilizer technology affects the overall energy efficiency

- Usage: Palm Oil, Palm EDIBLE OIL

- Type: Oil Extraction Machine

- Voltage: 380V/Customized

- Weight: 8000 KG

- Core Components: Motor, Pump, Other

- Oil type: Palm Oil

- Product name: Palm oil production line

- Raw material: Palm

- Function: pressing, solvent extraction ,refining

- finished product: edible oil

- application: oil factory

- factory visit: welcome

As outlined above, the type of sterilizer utilised in a palm oil mill can play a fairly significant role in the energy consumption of the palm oil production process. For example, a palm oil mill utilising the new horizontal sterilizer consumes 35 % less process steam than the vertical sterilizer.

- Why do palm oil mills use a horizontal sterilizer?

- This reduces much of the machinery associated with conventional sterilizers. In addition, there are cost savings in terms of manpower requirements, and maintenance. The horizontal sterilizer is the most commonly used sterilizer in palm oil mills.

- What are the different types of sterilizer in palm oil mill?

- Manufacturing Horizontal sterilizer, vertical sterilizer and tilting sterilizer,Sterilization is one of the key processes in any palm oil mill.For the production of palm oil, there are three types sterilizer for customer to choose: Horizontal sterilizer, vertical sterilizer and tilting sterilizer.

- Why is steam sterilization important in palm oil mill?

- In addition, steam sterilization of the FFBs facilitates fruits being stripped from the bunches. It also softens the fruit mesocarp for digestion and release of oil, and conditions nuts to minimize kernel breakage. Main stations in palm oil mill plant

- Why is palm oil sterilization important?

- This palm fruit sterilization step in the palm oil extraction process is crucial to the final oil quality as well as the strippability of fruits. Sterilization inactivates the lipases in the fruits and prevents buildup of free fatty acids (FFA). In addition, steam sterilization of the FFBs facilitates fruits being stripped from the bunches.

- Why is a cylindrical vessel sterilizer better than a vertical sterilizer?

- When disposed in a horizontal position, the cylindrical vessel sterilizer has fairly good disposition because the oil palm fresh fruit bunches placed in cages with a low stacking height are more uniformly spread out in this position across the length of the elongated vessel, as opposed to a vertical sterilizer.

- How does a continuous sterilizer improve fruit strippability?

- Continuous sterilizer showed improved fruit strippability, even with usage of low-pressure steam or atmospheric steam. The new system consists of conveyor belts taking crushed FFBs into the continuous sterilizer, where the fruits are sterilized and subsequently discharged. This reduces much of the machinery associated with conventional sterilizers.