PALM OIL PROCESSING Palm Oil Mill Machine Leading

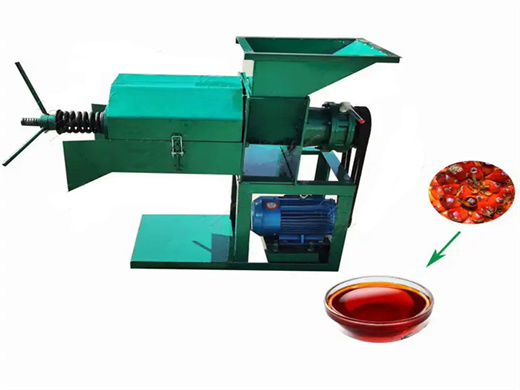

- Usage: Palm Oil

- Production Capacity: 95%

- Voltage: 380V

- Dimension(L*W*H): 1400*860*1260mm

- Weight: 280 KG

- Warranty: 1 Year

- Key Selling Points: Long Service Life

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Name:: oil press/extractor

- Raw material:: Palm, Palm, Palm, oil Palm,

- Application: Palm Oil Production Line

- Extraction of Oilseeds: 95% Oil Yield

- Method to press: screw squeezed press

- Oil rate: Meal Residual: 8%

- Advantage: Energy Saving Low Residual

- Process: mechanical pressing

- Application range: oil pressers

- Product name: oil pressers

3. 1 General processing description. Research and development work in many disciplines biochemistry, chemical and mechanical engineering and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a high yield of a.

The global price of palm oil, the most widely consumed edible oil, has been increasing since last year after the Covid-19 lockdowns cut output from plantations in Southeast Asia. Reuters reported on June that Malaysia’s benchmark crude palm oil price touched US$1,007.30 a tonne (Sh108,587) in mid-March, the highest since 2008.

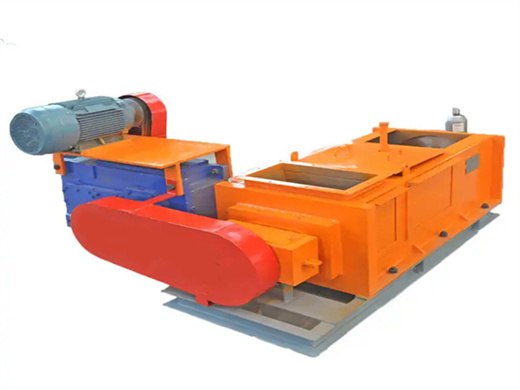

Palm Oil Farm Machinery & Equipment in Nigeria

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, Palm press oil plant for sale

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Power(W): 30KW

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 1200 Tons

- Oil getting method: pressing/extraction

- Heating way: steam

- Oil Color: Yellow

- Steam consumption: 900KG/T oil

- Water(soften water): 150Kg/T oil

- Alkali: Acid valuex1-3kg/T oil

- Circulating water cooling water yield: 150M3/H

- Waste bleaching earth oil content: <25~35%

- Refining rate: 1-refining consumption %

Hammer Mills. Popular . Quick reply . DIAMOND.. Palm kernel cracker/separator with other palm oil processing machines for full automated Complete 20,500,000.

This work discusses the palm oil mill processing carried out at Jugra Palm Oil Mill Sdn Bhd, situated at Sel angor, Malaysia with the capac ity of 45 t fresh f ruit bunch (FFB)/h. Typically, oil.

Local and Modern Methods of Crude Palm Oil Extraction

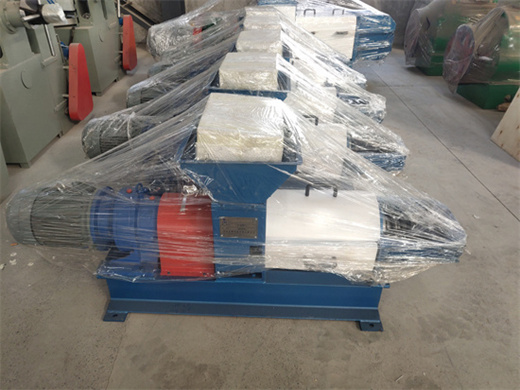

- Usage: Palm Oil

- Production Capacity: more than 98%

- Voltage: 220V/380V/415V

- Dimension(L*W*H): Depends on capacity

- Weight: 250 KG, 250kg

- Warranty: 1 Year

- Key Selling Points: Easy to Operate

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Product name: 300-500kg/h Palm oil press palm fruit plant

- Function: extraction Palm fruit oil

- Product type: Palm fruit oil press machine

- Diesel engine: 8HP

- motor: 5.5kw

- Processing capacity: 300-500kg/h

The secondary crude palm oil extract is obtained by further processing palm oil milling residues, such as palm oil mill effluent (POME), fiber, and pressed chaff. It involves recovering residual oil trapped in these by-products, typically through mechanical pressing, decantation, or solvent extraction.

Palm oil mill process flow diagram mainly uses the expression of graphical symbols, which can clearly express the structure of the whole palm oil mill and the operation process of the palm oil mill process. The entire palm oil mill process involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the.

3. PALM OIL PROCESSING Food and Agriculture Organization

- Usage: Palm Oil

- Type: palm oil refining machine

- Production Capacity: 360L

- Voltage: 380v

- Dimension(L*W*H): 1450*580*1540

- Weight: 1000 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pump

- material: stainless steel304 or 201

- Raw material: Palm Kernel

- standard: Palm oil

- oil purity: more than 99.8%

1 General processing description. Research and development work in many disciplines biochemistry, chemical and mechanical engineering and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a.

multifunctional seed oil mill with oil filter in indonesia

- Usage: Palm Oil, Cooking Oil

- Type: Cold & Hot Pressing Machine, hot press

- Production Capacity: 55-500kg/h

- Voltage: 220/380v

- Dimension(L*W*H): 1700*1200*1500mm

- Weight: 780 KG

- Core Components: Motor

- Oil type: Palm Oil

- Product name: oil making machine cold press

- Machinery type: Screw Oil Expeller Machine

- Raw material: Palm

- Oil yield: 40-50%

- Related machine: dryer,oil filter

- Output Capacity: 65-130kg/h

- Screw diameter: 80mm

- Application: for Palm oil making

- Advantage: High Oil Yield

Product Name: seed oil mill: Production Capacity: ≥400 kg/h (Customizable) Voltage: According to the local votage: Dimension(L*W*H) 2430*1250*2850mm: material of machine

- Can you set up a palm oil milling plant in Indonesia?

- Setting up a palm oil milling plant in Indonesia can be a lucrative venture, considering the country's status as the largest palm oil producer in the world. However, embarking on such a palm oil processing project requires careful planning and a thorough understanding of the costs involved.

- How much does a palm oil processing plant cost in Indonesia?

- The first critical step in establishing a palm oil processing plant is to obtain suitable land, the cost of which varies according to location, soil quality and accessibility. In general, prime agricultural land suitable for palm oil cultivation may cost between US$2,000 and US$5,000 per hectare in Indonesia.

- How to invest in palm oil processing mills in Indonesia?

- In the business of investing in palm oil processing mills in Indonesia, site selection is a crucial decision. Choosing the right location not only directly affects the factory construction process and the size of the investment, but also has a profound impact on the local economy, environment, agriculture and society.

- How is palm oil produced in Indonesia?

- Currently, the dominant palm oil production processes in Indonesia are modern, and these large mills typically employ continuous sterilization, threshing, and pressing processes to extract oil from the palm fruit bunches (As noted earlier).

- How much palm oil will Indonesia produce in 2023?

- Mr. Airlangga Hartarto, Indonesia's Coordinating Minister of Economy, said that Indonesia's total palm oil production will reach 56 million tons in 2023, and exports will reach 26.33 million tons. This figure not only shows the huge potential of Indonesia's palm oil industry, but also brings unlimited business opportunities to investors.

- Who is the largest palm oil company in Indonesia?

- In the realm of largest palm oil companies in Indonesia, Wilmar International commands attention. The company is involved in various aspects of the agricultural supply chain, including oil palm cultivation, processing, refining, and distribution of a wide range of products.