CHS expands Palm oil refining capacity at Mankato

- Usage: Palm Oil

- Type: Oil Pressing Machine

- Production Capacity: 50T/D

- Voltage: 380V

- type: Palm oil production line

- Residual oil in meal: ≤ 1%

- Solvent consumption: ≤3Kg/T (6 #solvent oil)

- Crude oil moisture and volatile matter: ≤ 0.30%

- Power consumption: ≤ 15KWh/T

- Finished meal moisture: ≤ 10-13% (adjustable)

- Residual solvent in finished meal: ≤ 300PPM (qualified detonated experiment)

- after-sale training: engineer will fly to your county to do the staff training .

- Steam consumption: ≤280Kg/T (0.8MPa)

- after-sale service: long-term technical service

Renovation driven by strong global demand in food and energy markets . ST. PAUL, MINN. (September 07, 2021) CHS Inc., the nation’s leading agribusiness cooperative, today announced a major Palm refinery expansion and renovation project at the CHS Mankato, Minn., Palm processing plant, driven by global oil demand.

In the U.S.A. and in Europe, for Palm oil refining, the caustic Palm oil refining process is by far the most used. The physical refining of palm oil, lauric oils and other fats and oils that have a low phosphatide content by dry degumming and bleaching followed by distillation, deodorization, is 20 to 25 years old and common practice today.

The application of phosphoric acid in vegetable oil refining machine

- Usage: Palm Oil

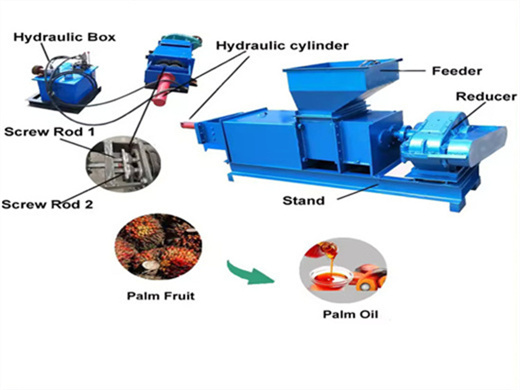

- Type: Screw Press Machine Palm Oil Pressing Extraction Machine

- Production Capacity: 200-300kg/h

- Voltage: 220V/380V

- Dimension(L*W*H): 1700*1400*1850mm

- Weight: 1100 KG

- Warranty: 1 Year

- Key Selling Points: Long Service Life

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pump

- Product name: oil press

- Function: Oil Making Machine

- Motor(KW): 11 Oil Machine

- Capacity: 6-8 oil press machine

- Feature: High Oil Yield Efficiency

- Spiral diameter: 100mm

- Spiral speed: 38r/min

- Raw material: Palm Kernel

- Advantage: High Oil Yield

1. In batch type vegetable oil refining plant: The acid degumming process generally proceed with alkali deacidification process together. After adding phosphoric acid, stir the oil for about 30 min, and then add alkali liquid to proceed the neutralization reaction.

Just feel free to know more about palm oil production and get more about palm oil refinery plant cost! Palm Oil Refining Process. Processing Flow of Small Scale Palm Oil Refinery: Crude palm oil → degumming (washing) → deacidification (alkali refining) → decolorization (clay adsorption) → dehydration (heating and drying) →.

Turnkey Project of Palm Oil Refinery Plant|Physical Refining

- Usage: Palm Oil

- Production Capacity: 20-2000TPD

- Voltage: 380V±10%

- Power(W): standard

- Dimension(L*W*H): standard

- Weight: standard

- After-sales Service Provided: Overseas third-party support available

- Production name: 20-2000tpd fullly automatic oil pretreatment machine price

- Manufacture range: 20-2000T/D

- Capacity: 500T

- Aavilable raw : Palm

- Palm oil yied: 15-20%

- Palm oil yied: 12-18%

- Oil color: LigLD yellow

- Materials: Carbon steel Q234R/ Stainless steel SS304/316

- Residue in cake: less than 1%

You are welcome to inquiry about detailed information about building a palm oil or palm kernel oil refining plant. Typical Proceess of Palm Oil Refining. Generally, palm oil refining machine includes: degumming, deacidification, decolorizing, deodorizing. Some of palm oil processing plant may also have fractionation process to enrich the final.

About Palm Oil: palm oil is a kind of vegetable oil that is the most produced, consumed and traded in the world. It is made from the fruits of oil palm tree. The palm fruit makes palm oil, while the kernel makes palm kernel oil. It is widely produced in Malayasia, Indonesia, and Nigeria. (Read more about palm oil processing>>)

Palm Oil Refining Process Unveiled Expert Guide

- Usage: Palm Oil

- Production Capacity: 100%

- Voltage: 220v/380V

- Dimension(L*W*H): According to your capacity

- Weight: According to your capacity

- Warranty: 1 Year, One Year

- After-sales Service Provided: Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

- Patent No.: ZL99252888.7

- Feature: High Oil Yield Efficiency

- Advantage: Energy Saving Low Residual

- Brand: HUATAI

- Material: S.S for deodorization pot, others in carbon steel.

- Application: Crude Palm Oil Refining plant

- Capacity: 1-5T

Complete Palm Oil Production Plant Layout. The refining of Palm oil, a process that removes impurities and enhances its stability, is a crucial step in ensuring the oil's superior quality. With its demand steadily increasing across industries, the market for Palm oil and its refined products is poised for further growth.

Palm oil refining machine

- Usage: Palm Oil

- Type: Continuous & semi-continuous refining

- Production Capacity: 90%

- Voltage: 220V/380V

- Dimension(L*W*H): 4150*900*2300mm

- Weight: 1400 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, Other, Gear

- Product name: oil refining machine

- Raw material: Palm Kernel

- Function: Oil refining

- MOQ: 1 Set

- Package: Wooden Case

- Application: Food Industry

- Operation: 1-2 Person

- Capacity: 1-10t/d

(developed in SWEDEN) in the refining of rapeseed oil. In the U.S.A. and in Europe, for the refining of Palm oil, the caustic refining process is by far the most used. We have not sufficient time to report on physical refining. Physical (steam) refining has advantages better yields better quality of fatty acids (purity and color)

- Who is developing palm oil plantations in Uganda?

- Wilmar International, one of the largest oilseeds corporations in the world is developing palm oil plantations in biodiverse islands off the coast of Lake Victoria, Uganda. The project is a partnership of Wilmar with the Government of Uganda, the International Fund for Agricultural Development (IFAD) and Kenyan oilseeds company Bidco.

- What is Uganda Oil Refinery?

- The Uganda Oil Refinery is a planned crude oil refinery in Kabaale village, on the Eastern shore of Lake Albert along the Hoima–Kaiso–Tonya Road, Buseruka Sub-county, Hoima District, Western Region, Uganda, near the border with the Democratic Republic of the Congo. It has been planned since 2010. Community opposition was repressed early on.

- Where is palm oil grabbing in Uganda?

- Land palm oil grabbing for in Uganda Wilmar International, one of the largest oilseeds corporations in the world is developing palm oil plantations in biodiverse islands off the coast of Lake Victoria, Uganda.

- Why is Uganda interested in palm oil?

- The Government of Uganda’s interest in the development of palm oil partly originates from the Comprehensive African Agriculture Development Programme (CAADP), and the government’s Vision 2040, National Development Plans, the National Agriculture Policy (NAP), and the Agriculture Sector Strategic Plan (ASSP).

- Who owns the oil palm project in Bugala Island?

- The project in Bugala Island in the Kalangala area is carried out by Oil Palm Uganda Limited (OPUL). OPUL is a subsidiary of Bidco Uganda, which holds 90% of its shares. Bidco Uganda is a joint venture formed between Wilmar International, Josovina Commodities and Bidco Oil Refineries, a Kenya-based company.

- Where is oil palm grown in Uganda?

- The best area for cultivation of oil palm in Uganda was found to be the Lake Victoria islands, notably the Ssese Islands (IFAD, 1997). Since 1998, the Government of Uganda has invested in domestic production and processing of vegetable oils to meet the increasing national demand.