Effect of different sterilization methods on the extracted

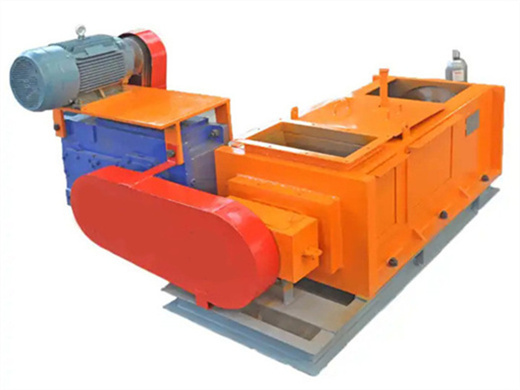

- Usage: Palm Oil, All kinds of oil Palm

- Type: Oil Extraction Machine

- Production Capacity: 5t/day-5t/hour

- Voltage: 220/380

- Dimension(L*W*H): 1400*860*1260

- Weight: 280 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Other, Gear, Bearing, Engine, Gearbox

- Oil type: Palm Oil

- Product name: Oli Press Machine

- Function: Making Palm Oil

- Application: Screw Oil Expeller

- Raw material: Palm

- Advantage: Energy Saving

- Material: 304 Stainless Steel

- Color: Customer Required

- Capacity: 750kg/h

Horizontal-sterilizer is the most commonly used sterilizer in palm oil mill palnt.When disposed in a horizontal position, the cylindrical vessel sterilizer has fairly good disposition because the oil palm fresh fruit bunches placed in cages with a low stacking height are more uniformly spread out in this position across the length of the.

One is mini palm oil mill plant for 1~10 ton/day factory, and the other one is 10~20 ton/day palm oil milling plant for small and medium-sized factory. Main Processing Equipments for Crude Palm Oil Mill Plant. The main equipment for small palm oil mill is palm fruits cooking and sterilizing tank, FFB Stripper and screw palm oil press machine.

How to filter crude palm oil? What machines will be used

- Usage: Palm Oil

- Production Capacity: 100% oil Palm Oil extractor

- Voltage: 220V/380V/440V

- Power(W): Depand on your capacity

- Dimension(L*W*H): Depand on your capacity

- Weight: Depand on your capacity

- Raw material: Palm

- Application: Palm oil Pressing

- Common capacity: 1-2000TPD

- Character: semi-auto, automatic

- Certificate: CE/BV/ISO9001

- Advantage: Energy saving/high oil yield

- Flowchat: cold press/hot press/prepress

In other words, the palm oil will be dried under the vacuum conditions. Palm oil filtration steps of new type palm oil mill plant. The above is the introduction of crude palm oil filtering methods and filtering steps, but they only the brief introduction, there are still more knowledge will be involved in the crude palm oil filtration process.

Old type palm oil processing machine. New type palm oil processing machine. Capacity. 1-2-3-5tph. 1-2-3-4-5tph. Sterilizing way. Use hot water boil bunches. Use boiler to provide steam or use hot water to boil bunches. Digesting part. Horizontal digester. Vertical digester. Pressing. Double screw press machine. New type palm oil press machine.

copr palm coco hydraulic extraction oil press machine in kabwe

- Usage: Palm oil pressing plant

- Production Capacity: 80kg/h, 500kg/h, 100kg/h

- Voltage: 220V/380V/440V

- Power(W): 22kw

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- Product name: Palm oil pressing plant

- Advantage: 40 years experience

- Application: Oil Production Line

- Production period: 45 days

- Installation period: 60 days

- Supplier Type: manufacturer

- Technology support: lifetime

copr palm coco hydraulic extraction oil press machine in kabwe . Type: Palm & Palm Kernel Oil Pressing Machine; Production Capacity: 98-100%; Voltage: 220V/380V

In order to set up palm oil mill plant, you need to make feasibility study based on market research about local situation, like how to source the palm fruits, where to sell your final products, where to get budget, where to set up the factory, what kind of permissions or certificates you need to apply from government, how to choose reliable.

factory sale by palm kernel oil processing machine in kabwe

- Usage: Palm Oil

- Type: all kinds of crude oil

- Production Capacity: 98%-100%

- Dimension(L*W*H): According to capacity

- Weight: 500 KG

- Warranty: 1 Year, 12months

- Key Selling Points: design as customized

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Product name: screw Palm oil press plant

- After-sales Service Provided: Engineers available to service machinery overseas

- Capacity: 1TPD-1000TPD

- Material of epuipment: stainless steel and carbon steel

- Final product: Palm oil

- Application: all kinds of crude oil

- Advantage: high oil out rate ,low oil loss

- Residual oil: less than 1%

- Color: As customized

factory sale by palm kernel oil processing machine in kabwe . Type: Palm & Palm Kernel Oil Pressing Machine; Production Capacity: 500-8000kg/h; Voltage: 220v/110v; Dimension(L*W*H): 60*27*38cm; Weight: 14 KG; Key Selling Points: Automatic; Marketing Type: Hot Product 2023; Machinery Test Report: Provided; Video outgoing-inspection: Provided

How Much Does a Palm Oil Mill Cost? BTMA Palm Oil Production Line

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, Palm oil pressing machine

- Production Capacity: 1TPD-500TPD

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Color: According to customer demand

- Production Material: Carbon steel, stainless steel

- Raw material: Palm

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical principle

- Warranty period: One year

- Factory visiting: Yes

In this article, we’ll delve into the factors that influence the cost of a palm oil mill, considerations to keep in mind, and provide estimates to help you gauge the investment required. Factors Influencing Palm Oil Mill Costs 1. Scale of Operation. The size and capacity of the palm oil factory significantly impact the overall cost.