Palm Oil Refinery Plant Palm Oil Refining Equipment

- Usage: Palm Oil

- Type: Palm Oil Fractionation Technology

- , Automatic

- Production Capacity: 100%, 5T-200T per hour

- Voltage: 380V/50HZ, 380V /440V or the local voltage

- Power(W): 15KW, According to the capacity

- Dimension(L*W*H): 1700*1100*1600mm, According to the capacity

- Weight: 1200kg, According to the capacity

- Supplier type: Factory(more than 35 years experience)

- Capacity: 5T-200T per hour

Crude Palm Oil (CPO) extracted by palm oil machine need to be further refined into edible oil in palm oil refinery plant. The purpose of palm oil refining is to get rid of the harmful impurities and needless substances in crude palm oil to improve the flavor, color and storage stability of palm oil.

Henan Glory's product range includes a wide range of edible oil refineries, which can be divided 1-20tpd batch type edible oil refining machine, 10-50tpd semi-continuous edible oil refinery plant and 30-1000tpd full-continuous edible oil refinery plant by type. Different types of edible oil refining equipment. Technology and Equipment

Edible Oil Refinery, Edible Oil Refinery Plant, Edible Oil Processing Machine

- Usage: Palm oil extraction

- Production Capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Power(W): Capacity

- Dimension(L*W*H): Palm oil extraction According to your request

- Weight: Palm oil extraction According to your request

- Processing: Batch-type or Semi-continuous

- Electric Consumption: 28Kwh/T Oil

- Soften Water:

- Phosphoric Acid:

- Bleaching Earth Consumption:

- Refining Rate:

- Waste Bleaching Earth Oil Content:

- Circulating Water Cooling Water Yield:

- Supplier Type:

- ITEM: Palm oil extraction

Edible Oil Refinery and Edible Oil Refining have been the areas of excellence for TINYTECH UDYOG. We are based in indonesia and since 1990 we have been the Basic Designers, Manufacturers and Exporters of complete Edible Oil Refinery Plants to convert the crude oils into pure RBD oils.

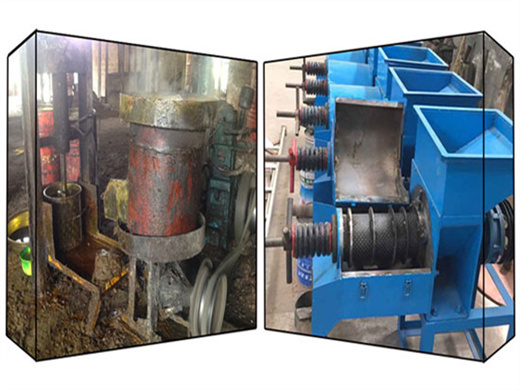

Batch Oil Refining Process (1~30 ton/day) This line of an oil refinery is perfect as a mini or small-scale palm oil mill plant. It requires low investment capital and a smaller occupation of land.

Cost of Establish Palm Oil Refinery Factory

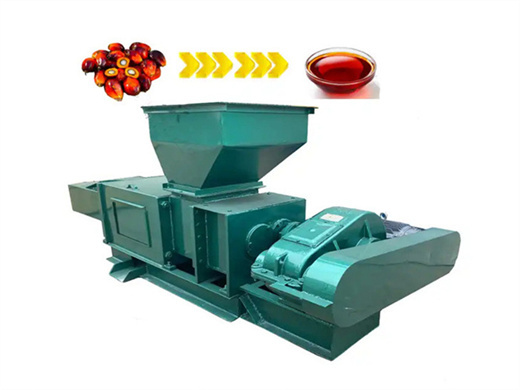

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, small Palm processing machine

- Production Capacity: 250-400 kg/h

- Voltage: According to customer demand

- Power(W): 21 KW

- Dimension(L*W*H): 2200*1600*2150

- Weight: 1300kg

- Color: White, green

- Production Material: Carbon steel, stainless steel

- Raw material: Palm

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical extruding

- Warranty period: One year

- Factory visiting: Yes

The cost of setting up a palm oil refinery factory or company in Malaysia should be the top concern for startups.To reduce the cost, make sure you select the right palm oil refinery equipment to enable efficient palm oil refinery process.

We receive many inquiries from Nigerian customers every month, and they want to know the cost of setting up a mini palm oil refinery plant in Nigeria. 1-2tpd mini palm oil refinery plant. Some of them have their own small scale palm oil mill plant, which produce crude palm oil, and then sell the crude palm oil to local palm oil refinery plant.

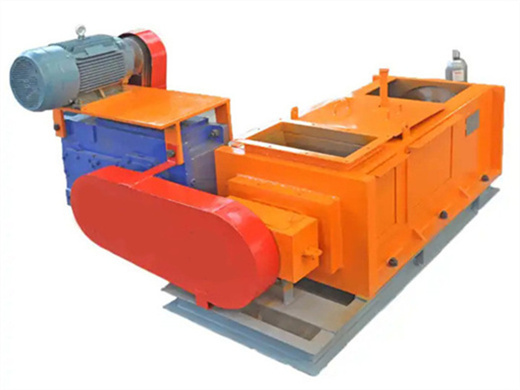

Edible Oil Refinery Plant, Edible Oil Refinery, Edible Oil Processing Machine

- Usage: Palm oil making machine

- Type: Palm oil making machine

- Production Capacity: 10T-300T/D

- Voltage: 220V/380V

- Power(W): Capacity

- Dimension(L*W*H): accoding to your capacity

- Weight: accoding to your capacity

- Item: Palmoil processing machine for home

- Processing: Leaching

- Production type: Edible oil

- Electric consumption: Low consumption

- Main material: Palm Oil

- Operation: PLC control

- Working life: Long

- Manufacturing experience: 35 years

- Supplier type: Manufacturer

- Texture: Mild steel and SS

We possess technological expertise in the manufacturing of Edible Oil Refinery Plants and Vegetable Oil Refinery Plants. Our machinery is suitable for crushing and refining of all types of oil seeds such as groundnut, Palm, soyabean, palm kernel, mustard, Palm, sesame seed, rapeseed, linseed, cotton seed etc.

Undertake Edible oil Refinery Plant from 1TPD to 500TPD

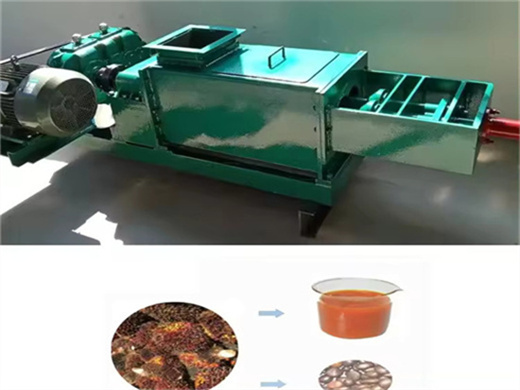

- Usage: Palm OIL

- Production Capacity: 3-5T/Day

- Voltage: 220V/380V

- Dimension(L*W*H): 1920*650*770MM

- Weight: 710 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, PLC, Gear, Bearing, Gearbox

- Capacity: 1-20T/Day

- Power: 5.5-22kw

- Guarantty Time: 12 Months

- Delivery Time: 15 Days

- Raw material: Palm Kernel

- Function: Making Palm Oil

- Color: Clients' Requirements

- Material: Carbon Steel Q235

- Advantage: Simple Operation

edible oil refinery With a growing world population, the demand for edible oil is also increasing year after year. Since most crude vegetable oils obtained either from expellers or solvent extraction plant contains impurities and need to be (at partially) refined for edible or technical applications, increased production volumes have resulted in a serious expansion of the edible oil refinery.

- How much does a palm oil refinery plant cost?

- The cost of palm oil refinery plant is affected by many factors Actually, the exact cost of a palm oil refinery machine would vary from the different requirements and specific situations. Usually, the equipment cost for setting up a palm oil refinery plant ranges from $ 60,000.00 to $ 300,000.00.

- What is the palm oil processing plant project report 2025?

- IMARC Group’s report titled “Palm Oil Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a palm oil processing plant.

- How a palm processing unit will increase palm oil production in India?

- October 204: Patanjali is set to establish a palm processing unit in Tripura, aiming to increase the local economy by enhancing palm oil production. March 2024: 3F Oil Palm launched India's first integrated oil palm processing unit, marking a significant step in the to increase domestic palm oil production in the country.

- What are the analysis and analysis of palm oil processing plant costs?

- This includes the analysis and detailed understanding of palm oil processing plant costs, including capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

- How does government support palm oil production?

- By providing financial assistance, governing agencies are encouraging farmers to increase production, ensuring a stable supply. Palm oil production is also supported through tax incentives, which reduce operational costs for businesses.

- Why did India launch national missions on edible oils & palm oil?

- In October 2024, India launched the national missions on edible oils and palm oil to increase its oilseed production and reduce reliance on imports. These initiatives focus on enhancing domestic production of edible oils and enhancing palm oil cultivation to meet growing demand.