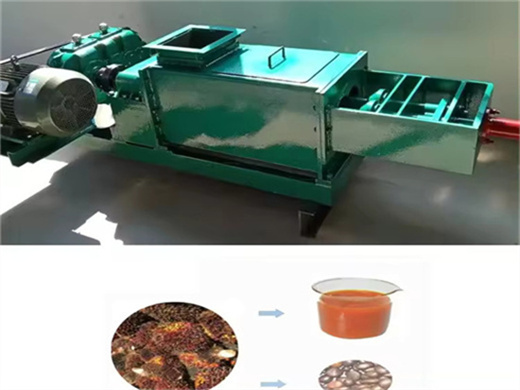

Palm Oil Processing Production Line Palm Kernel Oil Press Machine

- Usage: Palm oil mill

- Type: Cold & Hot Pressing Machine, Palm oil mill

- , Fully automatic

- Production Capacity: 10T-5000TPD

- Voltage: 220V/380V/440V

- Power(W): 10kw-50kw

- Dimension(L*W*H): 2500mm*2000mm*3000mm

- Weight: 2T-20T

- Materials: Carbon steel Q235 and SS304

- Water consumption: ≤ 0.3 t/t Palm

- Power consumption: ≤ 12kwh/t Palm

- Operate people: 2-3

- Circulating Water Cooling Water Yield: 150M3/H

- Supplier Type: Manufacturer

- Finished product: Grade 1 cooking oil

For small-scale palm processing farmers, HongDe Machine has designed single-screw and double-screw palm fruit oil press, which can process 1ton, 5 tons, 10 tons and 15 tons of palm fruit per hour. Reliable palm oil press machine with simple operation, gaining a good reputation in Africa and South America.

6. Palm Kernel Oil Press Equipment. The palm kernel oil press is the same as the conventional oil press and can be used in general. Throughpressing, we can get crude palm kernel oil. 7. Palm Kernel Oil Filtration Equipment. Crude palm kernel oil contains a lot of impurities, and palm kernel oil filtration equipment can enable us toobtain higher.

Palm Oil Processing Machine Palm Oil Production Line Palm Oil Refinery Machine

- Usage: Palm Oil

- Type: Vegetable Oil Processing Equipment

- Voltage: 380v

- Dimension(L*W*H): 5000*2580*2700

- Weight: 8000 KG

- Warranty of core components: 5 years

- Core Components: Gearbox

- Oil type: Palm Oil

- Product Name: ZX252

- Capacity: 20-25T/D

- Oil Rate: 5~8%

- Power: Y315M-6-45KW

- Company Type: Fatory

- Use For: Oil Press

- Advantage: High Oil Yield

- Function: Press Oil

- Material: Steel

Large Scale Continuous Screw Palm Oil Processing Machine. HongDe is leading & professional palm oil machine manufacturer and supplier in China. We provide 5-120TPH complete set machine for palm oil processing line at factory price, and undertake turnkey projects for customers.

Palm Oil Press Chart Flow: Palm Oil Press Station: Separate palm fruit and kernel, and Palm Oil Pressing Machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Process Flow of Palm Oil Press Processing Line: 1.

Palm Oil Pressing Machines

- Usage: Palm Oil

- Type: Vegetable Oil Processing Equipment

- Production Capacity: More than 95%

- Voltage: 220V/110V

- Dimension(L*W*H): 56*20*38 cm

- Weight: 20 KG

- Core Components: Motor, PLC, Gearbox

- Oil type: Palm Oil

- Product name: oil press machine

- Production: 10-13 kg/h

- Suitable for: Home or commercial use

- Product Material: Full stainless steel

- Press type: Hot & cold pressing

- Advantage: Industrial motor, double temperature control

After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).The pulp stone separation obtained CPO and stone, press machine adopts the double screw helix continuous discharge and hydraulic, greatly improving production efficiency.

Processing of palm fruit yields about 20% crude palm oil and 3% crude palm kernel oil. Palm Fruits Crude Palm Oil. The palm oil obtained from the pulp of the palm fruit is generally known as crude palm oil, which is not directly edible but can be processed into edible oil by refining equipment.

Palm Oil Pressing Process Introduction

- Usage: Palm Oil

- Production Capacity: 450 kg per hour

- Voltage: 220-240 volt

- Dimension(L*W*H): 840*240*540 mm

- Weight: 67 KG

- Warranty: 2 years

- Key Selling Points: High Productivity

- Machinery Test Report: Not Available

- Video outgoing-inspection: Not Available

- Warranty of core components: 2 years

- Core Components: Motor, Bearing, Gearbox, motor driver

- Thermostat: Temperature Control 600 Watt

- Gear Box: Helical Shaft Gear

- Energy Consumption: 850 - 1500 Watt/Hour

- Motor Power: 1,5 kW

The press process requires maximum extraction of palm oil from the pulp without crushing the kernels, as the crushed kernel oil will contaminate the crude oil and affect the quality. The crushing rate of nuts can be effectively reduced by using the secondary or multiple pressing process.

Good Performance Palm Oil Press Machine Palm Oil Milling Machine Small Scale Palm Oil Refining Machinery

- Usage: Palm Oil Press Machine For Sale

- Production Capacity: 30KG/H Oil Making Machine Price

- Voltage: 380V Nuts Oil Press

- Dimension(L*W*H): 800*650*1100mm

- Weight: 530kg

- Material: 304 Stainless Steel

- Function: Jackfruit s Oil Press

- Pressure: 55Mpa Nuts Oil Press

- Piston stroke: 450mm

- Feeding Diameter: 180mm

- Pressing Time: 7 Minute

- Raw material: vegetable,Palm,ginger,Moringa

- Application: Palm Oil Presser Machine

Screw palm oil pressing machine is widely used in small and large scale palm oil extraction plant. Why people tend to choose screw palm oil expeller press? The design of palm oil press machine is scientific and has higher oil extraction rate. And, the operation is relatively easy. So, palm oil press is popular in the market.

- How palm fruit is pressed in palm oil press machine?

- Palm fruit after digesting enters into oil expeller for palm oil pressing. After bunch reception, bunch sterilizing, threshing and digesting, the palm fruits are pressed into a screw palm oil press. Mixture of oil and cake will be extracted by use of palm oil press machine.

- How palm oil is extracted?

- Screw pressing is the main method of palm oil extraction. In pressing stage, mechanical screw palm oil pressing machine is used to extract the oil out of digested palm pulp which is a mixture of oil, water, fibre and nuts.

- How does a palm oil screw press work?

- Palm oil screw press is made of a rod-shaped punctured enclosure and a narrowly fitting screw running through it. The digested palm fruit mashes are unceasingly carried through the enclosure and taken to an opening that is restricted by a cone which generates the pressure needed to extract the oil via the cage perforations in the enclosure.