PRL advances upgrade of Papua New Guinea refinery Oil & Gas Journal

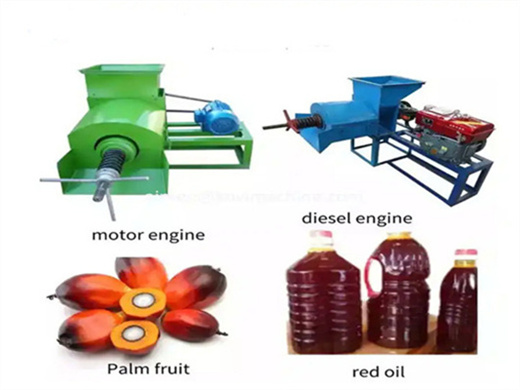

- Usage: Palm oil, Palm germ oil

- Core Components: Motor

- MOQ: 1set

- Application: Palm Oil

- port: qingdao/shanghai

- Packaging: container

- Weight: Based on capacity

- Color: according to customer's requirement

- quality: high quality

- After-sales Service Provided: Field installation, commissioning and training, Online support,attrValueId: 190000887

Robert Brelsford. Downstream Technology Editor. nigeria Refinery Ltd. (PRL) is moving forward with its previously announced plan to upgrade and expand its 55,000-b/d hydroskimming refinery along.

PALMOILMAGAZINE, Uganda One of the latest innovations in the palm oil industry is the application of artificial intelligence (AI) technology. This technology can automatically detect the maturity level of fresh fruit bunches (FFB) and count the number of FFBs at collection points.

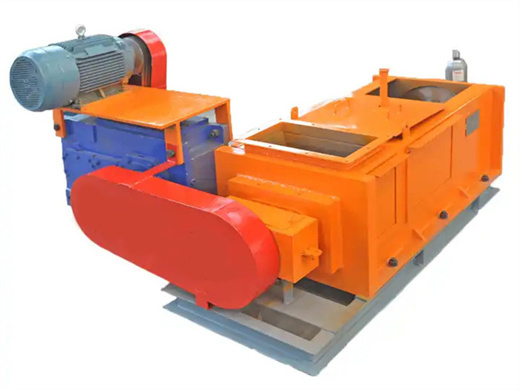

Edible Oil Refinery Plant Batch Type Small Scale Palm Kernel Oil Refining Machine

- Usage: Palm oil making machine

- Type: Palm oil making machine

- Production Capacity: 1-2000TPH

- Voltage: 220V/380V

- Power(W): 18.5KW

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- Equipment name: Palm oil making machine

- warranty: 1 year

- material available: Palm oil making machine

- texture: stainless steel, carbon steel, alloy steel

- projects done: 1-2000TPD complete oil lines

- markets: America, Europe, Africa, Asia, Australia

- delivery: within 1 month after the payment

- services: engineering, producing ,installation, construction

- Advantage: Energy saving, environment friendly

Our products include: Palm fruit /palm kernel pressing line: 1-2-3-5TPH small palm oil processing plant; 15-30-45-60-80-120TPH palm oil processing plant; 5-600TPD palm kernel oil processing plant; Palm oil refining: 1-2-3-5-10TPD batch palm oil refinery plant; 10-15-20-25-30-50TPD semi continuous palm oil refinery plant; 50-80-100-150-300.

Sucessful Palm Oil Refining Projects around the World. Mastering palm oil refining technology is akin to mastering alchemy, transforming ordinary fats into precious "green gold." In the "Palm Oil Refining Technology" column, we offer a panoramic view of the industry, unlocking the secrets of refinement, and opening the door to success.

a comprehensive guide to setting up the best Palm Oil Production Line

- Usage: Palm Oil

- Production Capacity: 200KG/H

- Voltage: 380/220V

- Dimension(L*W*H): 2040*840*1600

- Weight: 1400 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, PLC, Other, Gear

- Product name: refined palm oil ton

- Keyword 2: Palm refined Palm oil

- Keyword 1: Palm oil refined turkey

A comprehensive guide to setting up the best palm oil refinery plant should encompass the following key steps: market research and feasibility analysis, site selection, design and engineering, machine procurement and installation, and so on.

Palm oil fractionation is to separate palm oil into low melting point liquid phase (soft fat) and high melting point solid phase (stearin) by control the cooling and crystallizing process. Finally, the palm oil can be divided into 3 components: Palm Stearin (melting point around 50℃): Suitable for making margarine and shortening.

20TPD Continuous Palm Kernel Oil Refinery and Fractionation

- Usage: Palm Oil

- Production Capacity: 100%

- Voltage: 380V

- Power(W): Less than 85kw

- Dimension(L*W*H): according to the specification

- Weight: about 40ton

- type: Palm processing equipment

- Residual oil rate: 1%

- Materials: Carbon steel Q235 and stainless steel SS304/316

- Workshops: Expanding workshop,extraction workshop and refining workshop

- Patents: 23 patents

- Engineering achievements: hundreds of projects

- Invention patent: 7 invention patents

- Enterprise strength: TOP 10 OIL MACHIINE MANUFACTURER

- Research and development: Strong R& D team

- Warranty period: 1 year

Palm Kernel Oil Fractionation Knowledge. Palm kernel oil fractionation process can produce different palm kernel oil products at different melting points, including 8℃, 10℃, 14℃, 18℃, 24℃, 33℃, 44℃, 55℃, which greatly increase the added value of palm kernel oil and increase the economic benefits of Palm Kernel Oil Factory in Nigeria.

Palm Oil Refinery Plant Palm Oil Refining Equipment

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, home use oil expeller machine

- Production Capacity: 4-6KG per time

- Voltage: 220V

- Dimension(L*W*H): 310*190*270mm

- Weight: 12kg

- Warranty: 1 Year, 2 years

- Key Selling Points: Energy saving

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- After-sales Service Provided: Engineers available to service machinery overseas, Online support

- Application: Palm,sunfower seed

- Color: red

- Price: cheap

- Noise: small

- After sale service: best

- Machine quality: good

- Customer feedback: well

- Local Service Location: None

HongDe is the leading company in palm oil refinery field with years of experience in designing, installing and exporting of palm oil refinery plant. We supply various palm oil refining equipment and technology to ensure the best quality of palm oil with the lowest production cost. Contact us in the following form to get more information about.

- Why should Papua New Guinea develop a sustainable palm oil platform?

- This platform is designed in a way that these stakeholders may be able to develop a common vision and agenda, and ultimately implement them into a National Action Plan. Sustainable palm oil production holds the potential to boost many of Papua New Guinea’s development goals.

- What is the Papua New Guinea national interpretation 2014?

- The Papua New Guinea National Interpretation 2014 is based on the Principles and Criteria for Sustainable Palm Oil 2013 (P&C 2013). New Criteria, with associated Indicators, that have been added into P&C 2013 will be used as a standard for palm oil mills and plantations attaining certification under RSPO.

- Is Papua New Guinea a sustainable country?

- Being widely recognised for the fact that 95% of the country’s palm oil is rated as sustainable, Papua New Guinea is a global leader in premium palm oil produce, but the recent introduction of the palm oil and logging industries have begun to put a serious strain on the once evergreen landscapes of the country.

- Which provinces are suitable for oil palm cultivation in PNG?

- Map of PNG showing provinces and suitability for oil palm cultivation (source Trangmar et al. 1995). Province acronyms are: C, Chimbu; E.H., Eastern Highlands; S.H., Southern Highlands; W.H., Western Highlands.

- What is the Papua New Guinea agricultural development program?

- It was geared to improve the economic and social wellbeing of smallholder oil palm growers throughout Papua New Guinea by providing an appropriate field extension and development services comparable to that of the private sector as well as to reign over regulatory function of the industry on behalf of DAL.

- What is the Papua New Guinea national interpretation Task Force?

- eaPNG National Interpretation Task Force07 April 2017PreambleThe Papua New Guinea National Interpretation 2017 is based on the generic document of the Principles and Criteria for Sustainable Palm Oil 2013 (P&C 2013), which will be used as a standard for p