Sterilization Station Process Palm Oil Production Line Palm Oil Refinery Machine

- Usage: Palm Oil Presser

- Type: Oil Pressing Machine

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Power(W): According to the capacity

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Item: PalmGrinder

- Material: Stainless Steel 304

- Function: Oil press

- Advantage: Energy Saving

- Feature: High output

- Quality: Efficient

- Color: As your requirement

- Application: Palm ,etc.

- Turnkey Project: Yes

HongDe is leading & professional palm oil machine manufacturer and supplier in China. We provide 5-120TPH complete set machine for palm oil processing line at factory price, and undertake turnkey projects for customers. Welcome to consult us for Detailed Quotation. Email: [email protected]

Nut & Kernel Separation Station. HongDe is leading & professional palm kernel oil machine manufacturer and supplier in China. We provide complete machine of palm kernel oil processing line at factory price, and undertake turnkey projects for customers.

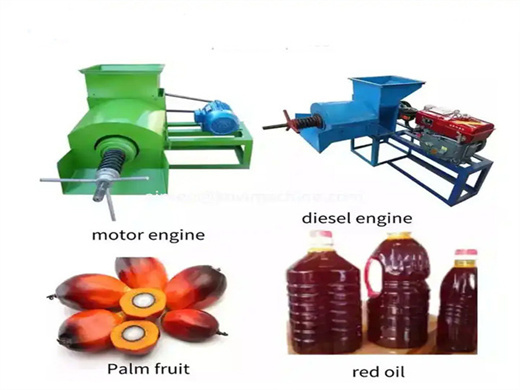

Palm Oil Press Machine FFB Oil Press Palm Oil Production Line Palm Oil Refinery Machine

- Usage: Palm Oil

- Type: Palm Oil Processing Machine Manufacturers

- Production Capacity: 100%

- Voltage: 380V/50HZ, 380V /440V or the local voltage

- Power(W): 15KW

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 1200kg

- Capacity: 5T-200T per hour

- Raw material: Palm

- Function: Palm oil press machine

- Application: crude Palm oil press machine

- Color: alternative

- Warranty: 365 Days

- Advantage: Energy Saving

- Supplier type: Factory(more than 35 years experience)

The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Process Flow of Palm Oil Press Processing Line: 1. Palm fruits through elevator and conveyors, enters into upper steaming boiler of palm oil press machine. 2.

palm kernel sludge and palm kernel shell which is used as a bio fuel can be gotten from palm kernel nuts. Palm kernel oil is processed to yield edible fats, soaps and candles and is used in the confectionery, pharmaceutical and perfume industries.

Palm Kernel Oil Mill Palm Oil Production Line Palm Oil Refinery Machine

- Usage: Palm Oil

- Production Capacity: above 98%

- Voltage: 220V/110V

- Dimension(L*W*H): 545*200*320 mm

- Weight: 12 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Engine

- Product name: Palm oil extraction machine

- Machine size: mini oil press machine

- Control mode: Automatic oil extraction machine

- Squeezing type: screw oil press machine

- Function: Oil Pressing

- Production: 6-8KG/H

- used for: Palm,beans,Palm etc

- Material: 304 SS materials body 316 stainless steel screw and chamber

- Machine color: silver

- keep working: 24 hours

The palm oil content is very high: common fresh fruit: 46~50%, palm kernel: 50~55%. As professional manufacturer of palm kernel oil mill machine, we can supply complete set of Palm Oil Mill Plant, complete set of palm kernel oil milling plant and complete set palm kernel oil refinery and CPKO fractionation plant.

1.The Palm fruit is conveyed to the mashing tank by screw conveyor 2.The mashing tank will break the fruit and heat it and discharge it to the press 3.The press squeezes the oil and the cake is used as a fuel for a steam boiler

Palm kernel oil extraction machine, Palm Oil Production Line

- Usage: Palm Oil, Palm,beans,Palm etc

- Production Capacity: 50%-55%

- Voltage: 180~240V,50-60HZ

- Dimension(L*W*H): 48*30*25cm

- Weight: 12 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Product type: small oil press machine

- Input: About 3kg raw material per hour

- Control mode: Automatic

- Application: Family

- Material: Stainless steel

- Keep working: More than 12 hours

- Shipping: by Express/ Air / Sea

Basic Unit Operations of Palm Kernel Oil Extraction Processing: · Palm Kernel Pre-treatment; · Oil Extraction; · Solvent Recovery From Oil and Meal; The following is the main advantages of palm kernel oil extraction machine and plant: 1. Fit for mass production of Palm Kernel Oil Extraction Machine; 2.

High Quality Palm Oil Production Line For Big Capacity

- Usage: Palm oil hexane extraction machine, Palm and many other kind of crude oil extraction

- Type: Palm oil hexane extraction machine

- Production Capacity: 10-3000TPD

- Voltage: 220V 380V or local voltage

- Power(W): Adjustable

- Dimension(L*W*H): Adjustable

- Weight: Adjustable

- Machine Name: Palm oil hexane extraction machine

- Solvent: Hexane

- Texture: Stainless steel or carbon steel

- Oil grade: Grade 1

- Residual oil in meal: ≤ 1%

- Whole Production Line: YES

- Turnkey Project: YES

- Engineers abroad service: Available

- After sales service: YES

This 500 kg/h Fresh Fruit Palm Oil Mill is a compact and efficient solution for small-scale palm oil production. Designed for farms, cooperatives, and small oil processing businesses, this mill provides a complete solution to extract crude palm oil from fresh fruit bunches (FFBs) with minimal labor and time investment.

- How palm fruit is pressed in palm oil press machine?

- Palm fruit after digesting enters into oil expeller for palm oil pressing. After bunch reception, bunch sterilizing, threshing and digesting, the palm fruits are pressed into a screw palm oil press. Mixture of oil and cake will be extracted by use of palm oil press machine.

- How palm oil is extracted?

- Screw pressing is the main method of palm oil extraction. In pressing stage, mechanical screw palm oil pressing machine is used to extract the oil out of digested palm pulp which is a mixture of oil, water, fibre and nuts.

- How does a palm oil screw press work?

- Palm oil screw press is made of a rod-shaped punctured enclosure and a narrowly fitting screw running through it. The digested palm fruit mashes are unceasingly carried through the enclosure and taken to an opening that is restricted by a cone which generates the pressure needed to extract the oil via the cage perforations in the enclosure.