Palm Oil Press Machine Palm Kernel Oil Extraction Machine

- Usage: Palm oil extraction plant

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 22kw/h

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 40tons

- Capacity: 10-500tpd

- Application: Palm

- Oil rate: 18-22%

- Processing capacity: 20tpd to 200tpd

- Steam consumption: ≤280Kg/T (0.8MPa)

- Power consumption: ≤ 15KWh/T

- Solvent consumption: ≤3Kg/T(6#solvent oil)

- Residual oil in meal: ≤1%

- Residual solvent in finished meal: ≤ 300PPM (qualified detonated experiment )

Better quality palm oil can be obtained through refining and fractionation. The first process of palm oil extraction begins at the palm oil extract plant, where fresh palm fruit bunches are received and processed. Next, let’s explore the process of palm oil extraction and some palm oil extraction machine: 1.Reception:

This paper gives an overview of the plant layout of palm oil processing and the scheduling operation, which includes bunch reception, fruit removal, bunches sterilization, digestion of the fruit.

The Ultimate Guide to the Palm Oil Production Process

- Usage: Palm Oil

- Production Capacity: above 98%

- Voltage: 220V/110V

- Dimension(L*W*H): 60*30.6*77.5 cm

- Weight: 50 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 2 years

- Core Components: Motor, Engine, Gearbox

- Product name: oil press machine

- Control model: full automatic

- Squeezing type: screw type

- Function: Oil Pressing

- Production: 20 kg/h

- used for: Palm,beans,Palm etc

- Material: SS materials body

- Certificaiton: CE,ROHS

- Machine color: silver

- keep working: 24 hours

The role of palm oil refinery plants. PALM OIL REFINING. Crude palm oil comprises the products of hydrolysis and oxidation as well as unwanted flavours and colours. Palm oil refinery plants are designed to eliminate these undesirable components. Palm oil refining involves four major steps. Step 1: degumming.

The Palm Oil Production Column will introduce the details of each process, providing you with the guidance and support you need for your palm oil business. Unveiling Palm Oil Production Process Steps Refining Process-Starting a Palm Oil Refining Plant Cost

Solvent Extraction Process-Palm Oil Production Plant

- Usage: Palm OIL, Cooking Oil

- Type: Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/110V

- Dimension(L*W*H): 46*26*36cm

- Weight: 8 KG

- Warranty: 1 Year, One Year avocado oil extraction machine

- Core Components: Motor

- Oil type: Palm Oil

- Product name: avocado oil extraction machine

- Raw material: Palm,moringa,camellia,perilla ,Palm

- Application: Edible Oil Production

- Advantage: High Oil Yield cooking oil making machine

- Material: Stainless Steel SS304/316

- Color: Sliver mini oil press machine

- Item: Edible avocado oil extraction machine

- Motor: AC motor with copper core

- Quality: Top Level

The primary objective of palm oil solvent extraction plant is to extract the palm oil from palm fruit bunches by the process of solvent?a petroleum by-product.Palm oil solvent extraction plant, nevertheless, is one of the best modern methods to extract palm oil at the very low temperature under void to produce outstanding quality of palm oil.

Fig. 18 Palm nut cracker (Ogunoroke Steele Construction Works Ltd, Nigeria) Fig. 19 Palm nut cracker combined with Kernel/Shell separator (Hormeku Engineering works, Ghana) 3.2 Process equipment design and selection criteria. In designing equipment for small-scale oil extraction one of the key factors to consider is the quality required.

Palm Kernel Oil Extraction Method Provided by Oil Press

- Usage: Palm Oil

- Type: Oil Pressing Machine, Palm cake oil extraction machine

- Production Capacity: 30TPD-1000TPD

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Color: Silver

- Production Raw material: Palm

- Work principle: Mechanical operating

- Warranty period: One year

- English manual: Yes

- Factory visiting: Yes

And the main producing countries are Malaysia, Indonesia, and Nigeria. The output of these three countries accounts for 88% of the world’s total palm oil production. And since 2004, the total amount of palm oil and palm kernel oil has been more than Palm oil, the world’s major edible oil, for the first time.

REVIEW OF PALM KERNEL OIL PROCESSING AND STORAGE TECHNIQUES

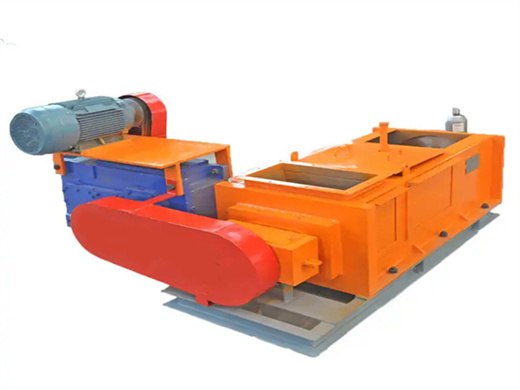

- Usage: Palm Oil

- Type: Oil Pressing Machine

- Production Capacity: 100TPD

- Voltage: 220V/380V

- Power(W): According to the Palm Oil expeller machine capacity

- Dimension(L*W*H): 1200*400*900mm3

- Weight: According to the Palm Oil expeller machine capacity

- Product name: Palm Oil expeller machine

- Material: Stainless Steel 304

- Color: According to the customer's request

- Warranty: 1year

- Function: Making Palm oil

- Advantage: High Oilput

- Quality: Efficient

- Model: 6YL-130-3

- Suitable for: Palm or other s

- Application: Oil Production Line

A Plant Design for Mechanical Extraction of Nmanu Aki (Palm Kernel Oil) Using Complete Pretreatment Process : Proceedings of the World Congress on Engineering and Computer Science 2012 Vol II.

- Why is palm kernel oil so popular in Nigeria?

- The Nigerian vegetable oil market uniquely features palm kernel oil packaged for household and commercial food frying. More than 60% of refineries in Nigeria are built on palm kernel oil as raw materials. This is because processing of palm kernel oil involves degumming, bleaching, deodorization, cooling, and packaging.

- Why do Nigerian vegetable oil refiners prefer palm kernel oil?

- As a result of the above, Nigerian vegetable oil refiners prefer palm kernel oil as raw material. Demand for vegetable oils in Nigeria is estimated at 1,968,500 tonnes, taking into account a per capita consumption of 12.7 kg and a population of 155 million in 2009 (WDI, 2011).

- What is the plant layout of palm oil processing?

- This paper gives an overview of the plant layout of palm oil processing and the scheduling operation, which includes bunch reception, fruit removal, bunches sterilization, digestion of the fruit, extracting of palm oil, clarification of oil, oil storage, and recovery of the kernel.

- Why was unfractionated refined palm oil not marketable in Nigeria?

- Unfractionated refined palm oil was not marketable to industrial end users in Nigeria hence the boom in the smuggling of refined bleached and deodorized palm olein from Malaysia and Singapore and the extraction of palm kernel oil for household frying.

- How much palm oil is consumed in Nigeria?

- Palm oil and palm kernel contribute about 65% to the total vegetable oils and fats consumed in Nigeria. This implies that palm oil and palm kernel oil demand and supply is 1,279,525 tonnes and 739,427 tonnes, respectively, leaving a gap of 540,098 tonnes annually.

- Is palm oil production a problem in Nigeria?

- Furthermore, the survey of an area in Nigeria was also carried out to ascertain factors affecting the production of palm oil and individual view on the impact of processing. Due to the yield in oil palm enterprise, if the sector is judiciously managed, it will be a source of solution to problems that Nigeria is experiencing.