Revolution of Enzymatic Technologies in Palm Oil Industry

- Usage: Palm Oil

- Production Capacity: 210kw

- Voltage: 380v

- Dimension(L*W*H): 8*2*4m

- Weight: 6000 KG, 6T

- Warranty: 1 Year

- Key Selling Points: Long Service Life

- Marketing Type: 2022 new

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing

- Power: 2.2kw

- After-sales Service Provided: Engineers available to service machinery overseas

- Packing: Standard Packing

- Key words: efficient oil refining equipment

- Engine: 7HP Engine

- Product name: Oil Refining Production Line

? Malaysia is currently the second largest producer and exporter of palm oil worldwide. Malaysia supply a total of 32% in which is 19.96 million tons of total output for the global palm oil production in year 2015. In 2015, Malaysia palm oil export reached RM 40.14 billion and accounted for 5.1% of the total exports. Why Palm Oil?

Biodiesel from enzymatic transesterification of palm oil waste streams Enzyme biodiesel processing of palm oil waste streams will reduce recycling and significantly improve CPO quality 300 tpd Enzymatic biodiesel plant at High Plains Bioenergy, USA Flexibility Flexibility on feedstock, eg CPO, high FFA CPO, PFAD, Acid Oil Simpler Process

ENHANCEMENT OF PALM OIL EXTRACTION USING CELL WALL DEGRADING

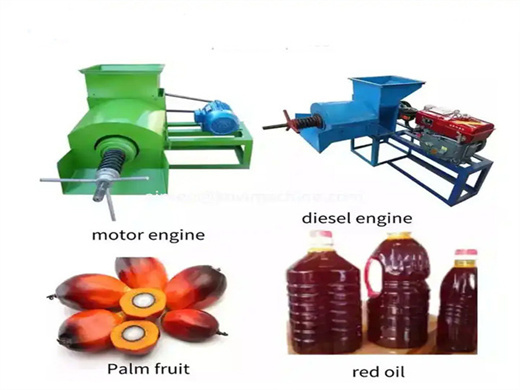

- Usage: Palm OIL

- Type: Automatic Palm Fruit Oil Processing Machine

- Production Capacity: 60%

- Voltage: 220V/380v

- Dimension(L*W*H): 1200*780*1100mm

- Weight: 300-2000KG

- Warranty: 1 Year

- Key Selling Points: High Productivity

- Local Service Location: None

- After-sales Service Provided: Free spare parts, Field installation, commissioning and training, Video technical support, Online support

- Raw material: Palm Kernel

- Capacity: 100kg/h

- Advantage: High Oil Yield

- Package: Wooden Case

- Market: Global

- Application: Palm

- Quality: 15-150KG/H Palm Oil Making Machine Palm Oil Press Machine

- Method to press: hydraulic Press

- Keyword 1: Hydraulic Cold Press Palm Oil Extractor

crude palm oil is further processed to remove among others, a signi?cant quantity of FFA and to obtain re?ned, bleached, and deodorized oil (RBDO). The oil that was not extracted remains in the solid residue and ends up as waste oil. However, aqueous enzymatic oil extraction can be employed in our palm oil industry due its potential as

Aqueous enzymatic extraction of oil from the palm pulp was performed by using a mixture in the range from 0 to 1.0 % of enzyme preparations Cellic CTec2, Cellic HTec2 and Pectinex Ultra SP-LThe highest oil yield of 88.0 % was obtained at the optimal amounts of these enzyme preparations taken in the mass ratio of 0.46:0.34:0.2 %, respectively .

Enzymes in Oil Refining, Present and Future Extended title

- Usage: Palm Oil

- Voltage: 380V

- Dimension(L*W*H): depends on the capacity

- Weight: 100000 KG

- Warranty: 1 Year

- Key Selling Points: Long Service Life

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, PLC

- Product name: Palm oil production line

- Capacity: 5-5000 Tons per day

- Machine color: Depends on your requirement

- Solvent residual(mg/kg): 0 after crude oil refinery

Novozymes offer wide-range of enzymatic solutions across the palm value chain Specialty oils & fats Palm oil extraction Palm oil mill Palm oil refining (3-MCPD) Palm biodiesel Palm oil refinery Specialty fats producer Biodiesel producer Cooking oil Margarine & shortenings CBE OPO, etc. Low trans fat and 3-MCPD Biodiesel

the present invention provides an enzymatic process for extracting oil from oil palm fruits with improved efficiency and/or increased yield comprising steps of: incubating the mixture containing mashed mesocarp portion or mesocarp containing mashed oil palm fruit mass, water and enzyme composition of the present invention at about 25-65 degree Celsius for atleast 60 -.120 minutes and.

ENZYME ASSISTED TECHNOLOGY TO IMPROVE PALM OIL EXTRACTION YIELD

- Usage: Palm Oil, Palm EDIBLE OIL

- Type: Oil pressing machine

- Production Capacity: 30-60kg/h

- Voltage: 220V

- Dimension(L*W*H): 1200*780*1100

- Weight: 380 KG

- Core Components: Bearing

- Oil type: Palm Oil

- Raw material: Palm Fruit

- Function: Press Oil s

- Application: Oil Production Line

- Advantage: Energy Saving Low Residual

- Used for: Oil Making Expeller

- Extraction of Oils: 90% Oil Yield

- Machinery type: Automatic Screw Oil Mill Machine

- Quality: Top Level

- Processing Types: Screw Pressing

- Method to press: Screw Squeezed Press

Palm Fruit Composition FFB Fruits EFB Debris 100Kg 65.7Kg 10Kg 24.3Kg Oil Extraction rate 20.34Kg Mill Oil Loss 1.86Kg Bound oil Loss 3.82Kg Oil to Bunch 26.02Kg MF : 0.4 0.6% Loss EFB : 0.4 0.6% Loss POME : 0.7 1.0% Loss FFB : Fresh Fruit Bunch MF : Mesocarp Fiber EFB : Empty Fruit Bunch

OPTIMISATION OF ENZYMATIC SLUDGE PALM OIL RECOVERY FROM Palm Oil Processing Plant

- Usage: Palm Oil, Palm EDIBLE OIL

- Type: Cooking Oil Press Machine

- Production Capacity: 50-1000kg/h

- Voltage: 380V

- Dimension(L*W*H): According to your capacity

- Weight: According to your capacity

- Warranty: 1 Year, 12 Months

- Advantage: Energy Saving

- Raw material: Palm

- Extraction of Oils: 96% Oil Yield

- Character: Professional Manufactuer

- Application: Oil Production Line

- Feature: High Oil Yield Efficiency

From the RSM-generated model, the optimum conditions for extraction of oil from POME were identified to be at an enzyme concentration value of 0.25% in 81.46 hr reaction time, with a rotation speed of 111.05 rpm. Predicted oil yield was 93.56% while the experimental oil yield was 81.95% as revealed by the One Sample T-Test of confirmatory studies.

- Can aqueous enzymatic oil extraction improve palm oil extraction?

- In the present study, a new blend of enzymes, CTe2, HTec2 and Pectinex Ultra SP-L, was tested on aqueous enzymatic oil extraction process to achieve high performance extraction of palm oil from palm mesocarp. AEOEP is certainly an alternative way for palm oil extraction being an environmentally friendly process.

- What is the optimum enzyme mixture for palm oil extraction?

- Predicted optimum enzyme mixture was verified at 98% confidence interval of predicted value (experimental value of 88.36% oil extraction and 16.55 g/L sugar extraction yield). As quoted earlier, a maximum palm oil recovery of 90-93% was achieved with enzyme mixture of tannase, cellulase and pectinase at optimized hydrolysis conditions.

- How enzymatic technology will benefit palm oil industry?

- Enzymatic technologies are likely to bring benefits in many areas: greater efficiency, saving in natural resource, lower energy consumption, and lower production cost. Compared with traditional approaches, the more specific and cleaner enzymatic will promote the continued trend towards sustainable processes in palm oil industry.

- Why is tannase used in palm oil extraction?

- The use of tannase led to an increase in total phenolic compounds in the lipophilic and hydrophilic fractions, resulting in and a higher antioxidant capacity of the oil. This process is an environmentally friendly means for high quality palm oil extraction.

- What is the best enzyme mixture for aqueous enzymatic oil extraction?

- This study aims to characterize oil palm fruit mesocarp and formulate best enzyme mixture for aqueous enzymatic oil extraction. The fresh oil palm fruits (Elaeis guineensis) and mass passing to digester (MPD) samples were kindly provided by Sime Darby East Palm Oil Mill, Carey Island, Selangor and were kept frozen prior to use.

- What enzymes are used in oil extraction?

- The extraction efficiency and quality of the oils depend on the combination of the applied enzymes (Lamsal et al., 2006). The enzymes for oil aqueous enzymatic extraction that are most frequently reported in the literature are protease, α-amylase, cellulase and pectinase (Rosenthal et al., 1996).