Palm Oil Processing Plant Quality Management Plan

- Usage: Palm Oil

- Type: Centrifuge Extraction Machine

- Production Capacity: 500KG/H

- Voltage: 220V/415V/440V

- Dimension(L*W*H): 9*1.5*2.5M

- Weight: 3500 KG, 3500KGS

- Core Components: Motor, PLC, Bearing

- Oil type: Palm OIL

- Product name: Palm Oil Extraction Line

- Extraction method: Centrifuge Extraction

- Core equipment: Decanter and Separator

- Equipment material: Stainless steel 304

- Capacity: 200-400KG/H

- Installation power: 22kw

- Oil yield: 13.5%

- Cover space: 9*1.5*2.6M

2 Project Quality Assurance Quality Assurance of the Palm Oil Processing Plant is achieved by specifying quality project. (1998), Managing Quality: Free press, N. Y. 7. Kolarik W. J. (1999.

Quality control for the Palm Oil Processing Plant will be achieved by defin ing the relevant qualit y criteria for the outputs, or what characteristics make them ‘fit for purpose’. 3.1 Output.

Food quality assurance of crude palm oil: a review on toxic

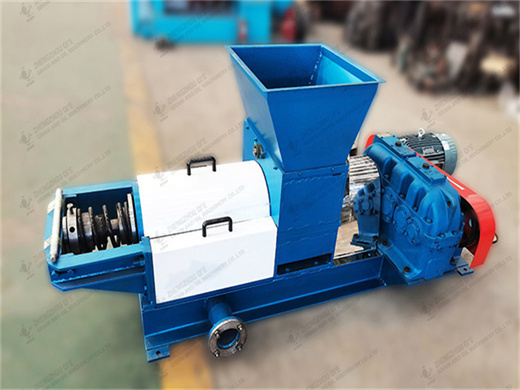

- Usage: Palm Oil

- Production Capacity: 150-230KG/H

- Voltage: 110v-220v-380v

- Dimension(L*W*H): 1800*1200*1500mm

- Weight: 1100 KG

- Warranty: 1 Year

- Key Selling Points: Easy to Operate

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Other

- Product name: oil pressing machine

- Raw materials suitable: seeds

- Machinery type: Single Oil Making Machine

- Color: Customers' Requirements

- Used for: oil extraction

- Function: Making Palm Oil

Halim RM, Ngan MA. 2001. Effect of temperature on the quality of fresh crude palm oil at different stages of processing. Oil Palm Bull 43: 31?37. [Google Scholar] Hassan A, Mohammad JA. 2005. Regulations on Quality of FFB. Oil Palm Bull 50: 31?38. [Google Scholar] Hawari Y, Halim RM, Aziz AA. 2018.

of palm oil and its fractions in the numerous fatty-foods[1]. The fractionation technique is the major modern modification method utilized especially for palm oil separation[2, 3]. It is worthy to mention that, palm oil production is still increasing rapidly in recent years and turn into the world’s most-produced and consumed oil[4]. In edible

a comprehensive guide to setting up the best Palm Oil Production Line

- Usage: Palm Oil

- Type: Oil refinery

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 10-50kw

- Dimension(L*W*H): 46*32*36cm

- Weight: 30tons

- Raw material: Palm

- Application: crude oil refinery

- Product name: crude Palm oil equipments

- Handling capacity: 5tpd-300tpd

- Power consumption: 18.8kw/h

- Steam consumption: 300kg/t

- Refinery rate: 96%

- Refinery method: Physical and Checmical

- Advantage: Energy Saving

Establish a strict palm oil refinery machine quality control system to monitor key parameters during the refinery process to ensure stable product quality. To sum up, setting up the best palm oil refinery plant requires comprehensive consideration multiple aspects to ensure that the palm oil refinery process is efficient and stable.

With over 20 years of experience in the quality assurance & food safety field, she is currently focused on transforming GAR’s palm oil refinery operations by establishing a fully integrated, digitalised system that will position the company at the forefront of Industry 4.0 innovation.

Palm Oil Producing Countries Quality Assurance For the EU

- Usage: Palm oil milling equipment

- Type: Palm oil milling equipment

- Production Capacity: 5-100T/H

- Voltage: 220V/380V/440V

- Power(W): 100kw

- Dimension(L*W*H): Depend on the capacity

- Weight: Depend on the capacity

- Raw material: Palm

- Process type: Palm oil milling equipment

- Water cosumption: ≤ 0.5 t/t material

- Power consumption: ≤ 15 kw*h/t material

- Steam consumption: ≤ 320 kg/t mateiral

- Manufacturing experience: mroe than 30 Years

- Advantage: Energy Saving

- Solvent consumption: ≤ 3 kg/t material

- Workshop name: Palm oil milling equipment

- Service: Arrange engineers

The value of the palm oil industry in tropical forest conservation has long been presented by palm oil producing countries as essential to global sustainability. Its tiny footprint compared to other vegetable oils is clear indication that it has a critical role to play as a sustainable source of food and fuel.

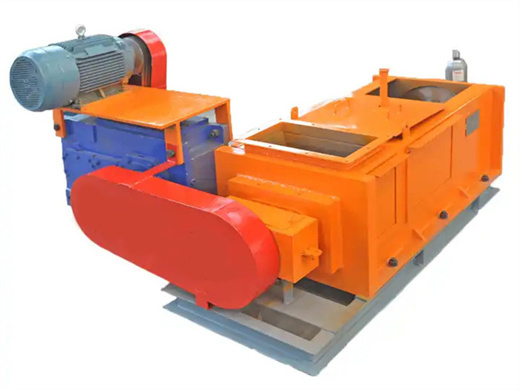

Quality Assurance Oil Mill & Oil Extraction Machinery

- Usage: Palm Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V/50HZ triphase

- Dimension(L*W*H): 1055*805*345mm

- Weight: 27.1 KG

- Warranty: 1 Year, 1year

- Core Components: Motor, Engine

- Oil type: Palm Oil

- Advantage: High Oilput

- Character: Easy Movable

- Function: Oil Pressing

- Color: Customer Required

- Quality: High Level

- Operation: Easily

- Model: TS-BXG-128

At Tinytech Udyog, our commitment for excellence and passion for quality oil mill products have shown as the way to growth and prosperity.The entire ranges of our products are finished at the apex of latest engineering techniques; making Tinytech Udyog a hallmark of quality.

- What is a palm oil press machine?

- The common used Palm Oil Press Machine is double screw palm oil expeller. Huatai Oil Machinery is a China leading palm oil processing machine manufacrtuer and supplier, offering the factory price equipmnet and palm oil production process design at low cost, have built mutiple Palm Oil Mill projects with customized production process in Nigeria.

- Why should you choose Huatai oil machinery for palm oil production line?

- High quality high oil yield and design of Palm Oil Production Line is the key to success of palm oil plant business. Huatai Oil Machinery is leading professional manufacture and supplier of palm oil production line equipment includes palm fruit oil press and palm kernel oil extraction, CPO Refinery, and palm oil fractionation.

- What is a palm oil processing machine?

- The complete set palm oil processing machine includes palm oil extraction process (how palm oil is extracted), Palm Kernel Oil Extraction Process and palm oil/palm kernel oil refining process. Oil palm is an important tropic oil seed plant. The palm oil content is very high: common fresh fruit: 45~50%, palm kernel: 50~55%.

- What is palm kernel oil production machine?

- Palm kernel oil production machine is suitable for both small and large palm kernel oil mill plant. The complete set of palm kernel oil production machine includes palm kernel oil pretreatment and press machine, palm kernel cake solvent extraction plant and palm kernel oil refinery machine. 1. Raw Materials Reception Station

- What are traditional palm oil processing methods in Indonesia?

- Traditional palm oil processing methods in Indonesia have a long history, including manual extraction using simple tools. These traditional methods are still prevalent in some small-scale and remote areas, but tend to be inefficient and labor-intensive.

- What is 1-5 tph palm oil processing plant?

- 1-5TPH palm oil processing plant is a small scale processing line, but it's specially designed by our professional engineers, for its low cost and high production rate is very suitable for most small and medium palm oil mill.