MALAYSIAN PALM OIL INDUSTRY PERFORMANCE 2023 ISP

- Usage: Palm Oil

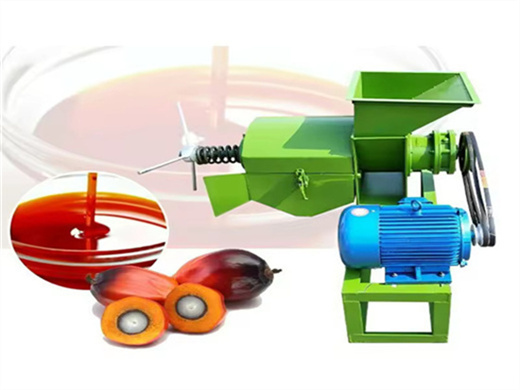

- Type: 10t/d Palm oil machine, mini Palm oil screw press price For Multi Palm Oil

- Production Capacity: 10t/d

- Voltage: 380V

- Power(W): 15w

- Dimension(L*W*H): 2500x1600x2500mm

- Weight: 950 kg

- staff requirement: 1-2 persons to 10t/d Palm oil machine

- space requirement: 60-80 square meter for 10t/d Palm oil machine

- usage: press oil Palm/material Palm oil, Palm fruit

- Color: according to customer's requirement

- Operating ways: Safe and simple

- quality: life-long machine

- features: low investment and high output

- Application: 10t/d Palm oil machine For Multi Palm Oil

The Malaysian palm oil industry witnessed mixed performance in 2023 as against 2022. CPO production, FFB yield, OER and stocks of palm oil registered increases. HIGHLIGHTS OF THE 2023 PERFORMANCE 3 Sufficient supply situation had pushed down prices to below RM4,000/tonnes after breaking a new record high in 2022.

Malaysia is the second leading producer of palm oil worldwide, supplying around a third of the world’s palm oil. Palm oil is one of Malaysia’s primary industries, contributing 2.4 percent to.

ART-00091 00 91-Palm Kernel Oil Extraction The

- Usage: Palm OIL

- Production Capacity: 100%

- Voltage: 220V/380V

- Dimension(L*W*H): 900*1250*1750mm

- Weight: 1500 KG

- Warranty: 1 Year, 12 Months

- Key Selling Points: Energy saving

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Other

- Raw material: Palm Kernel

- Material: Iron, stainless steel

- Quality assurance: CE,ISO

- Capacity: 100kg/hour

- Function: Making Palm Oil

- Advantage: Energy Saving

- key words: Palm oil press machine

- Place of origin: Henan,China

1) Mechanical extraction and direct solvent extraction are the two main methods used in Malaysia to extract oil from palm kernels. 2) Mechanical extraction involves size reduction, flaking, and screw pressing of kernels. Direct solvent extraction uses solvents in larger plants and has higher oil recovery. 3) A third method uses pre-pressing followed by solvent extraction to achieve higher.

Despite the fact that palm oil plays a major role in satisfying global demand, the sector faces social and environmental issues that call for sustainable practices and programs like the Roundtable on Sustainable Palm Oil (RSPO) to address issues related to the production of palm oil. Malaysia is the second highest country for palm oil.

OIL PALM ECONOMIC PERFORMANCE IN MALAYSIA AND R&D

- Usage: Palm oil press machine for sale

- Production Capacity: 100% oil press machine

- Voltage: 220V/380V/440V

- Power(W): 5.5~18.5KW

- Dimension(L*W*H): 1950*1300*1900, according to the capacity

- Weight: 950KG

- Raw material: Palm

- used for: Palm oil press machine for sale

- Application: Oil Pressing

- Common capacity: 80-600kg/h

- Warranty: One Year

- Character: oil press machine

- decoloring time: 15-20min

- Moisture: 3%

- residual oil in cake: 2%

Malaysia is the second largest palm oil producer in the world. This review article highlights the performance of the industry in 2023 and the recent R&D progress throughout the entir e supply chain.

The overall palm oil milling efficiency in terms of oil recovery is typically about 90?93%, depending on plant machinery and process control. The typical crude palm oil extraction rate (OER) during the milling process is in the region of 18?23% by weight to FFB, while the palm kernel extraction rate (KER) ranges between 4 and 6%.

Palm Oil Production Line. Tailor-made Palm Oil Mill Plant

- Usage: Palm OIL

- Voltage: 220v/110v

- Dimension(L*W*H): 43x27x35cm

- Weight: 11 KG

- Warranty: 2 years

- Key Selling Points: Automatic

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- type: Sr-X5

- capacity: 3.5-5.5kg/h

- power: 610w

- working hours: 24hours per day

- Raw material: Palm Kernel

The nuts are sent to the nut silo. The palm kernel will be recycled from the nuts by the cracking machine. The palm kernels are further processed in the palm kernel oil extraction plant to produce palm kernel oil (PKO) and palm kernel cake (PKC). Equipment: Nut and fiber separator, nuts cracker, Palm kernel oil press.

Solvent Extraction Plant Eonmetall

- Usage: Palm oil extraction machine

- Type: Palm oil extraction machine

- Production Capacity: 400~600kg/h

- Voltage: 220V/380V

- Power(W): 18.5kw

- Dimension(L*W*H): 1500*1600*2500mm

- Weight: 2000kg

- Keywords: Palm oil extraction machine

- Raw material: Palm

- Advantage: Energy Saving

- Machine Material: Part of are stainless steel

- Warranty: 1year

- Residual: Less than5%

- Supplier strength: with 30 years experiences

- Machine color: According customer needs

- Product name: Palm oil extraction machine

- Business type: manufactory

A food grade solvent known as hexane is used to extract the remaining 5% 6% of residual crude palm oil (CPO) available in palm-pressed fibre, thereby enhancing oil extraction rate (OER) by 0.5%. Palm Kernel Oil Extraction (PKOE) Plant, is designed to extract the oil from kernel cake by means of solvent. This shall extract an additional 3% PKO.

- Who is the largest palm oil company from Malaysia?

- The Rank of 10 Largest Palm Oil Companies from Malaysia Based on Net Income in 2023 Sime Darby Guthrie still became the largest palm oil company from Malaysia based on planted area and net income in 2023. Officially, this company is headquartered in Petaling Jaya, Malaysia.

- Are oil palm plantations in Malaysia more productive than in Indonesia?

- In terms of land productivity, oil palm plantations in Malaysia are more productive than in Indonesia, when calculated from the yield of fresh fruit bunches per hectare. However, Malaysia's development area is already limited due to its small size. Therefore, many Malaysian companies are expanding to open land in Indonesia.

- Who is TH Plantations Sdn Bhd (THP)?

- TH Plantations Sdn Bhd (THP) was incorporated under the Company Act 1965 and has become an active oil palm contributor in Malaysia’s oil palm industry. TH Plantations’ core business comprises of two, which are the cultivation of oil palm and production of crude palm oil (CPO) and palm kernel.

- How many palm oil plants are there in Malaysia?

- Of the total land area, there are 295 thousand hectares of oil palm in Malaysia, 182 thousand hectares in Indonesia and the rest in other countries. Furthermore, Sime Darby has also processed plants and facilities of 68 palm oil mills, 11 kernel crushing plants, and 5 R&D centers.

- Which country produces the most palm oil in 2023?

- 10 Largest Palm Oil Companies from Malaysia- Malaysia still become one of the world’s largest country producers of Palm Oil in 2023. According to the report of FAO Statistical Corporate Database (FAOSTAT) in 2022, the production of oil palm fruits from Malaysia reached 92 million tons.

- What is Malaysian palm oil board (MPOB)?

- The states of Sabah and Sarawak on Borneo Island, as well as Peninsular Malaysia, are particularly renowned for their extensive plantations that stretch across hectares of land. The Malaysian Palm Oil Board (MPOB) oversees the development and regulation of the palm oil industry in Malaysia.