Oil Extraction Process Explained: 7 Steps You Need to Know

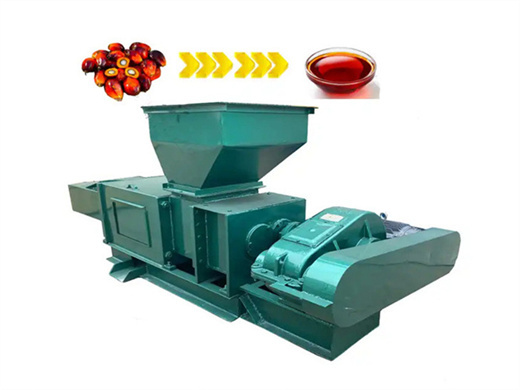

- Usage: Palm Oil press

- Type: Oil Pressing Machine

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Power(W): According to the capacity

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Item: Palm Separation Machine

- Material: Stainless Steel 304

- Function: Oil press

- Advantage: Energy Saving

- Feature: High output

- Performance: Excellent

- Color: As your requirement

- Application: Palm,etc.

- Turnkey Project: Yes

Various oil extraction methods and oil extraction techniques ensure the maximum recovery of oil, making it a vital component of the global energy supply. The continuous advancement in petroleum extraction technologies promises even greater efficiency and sustainability in the future.

The oil palm tree is an ancient tropical plant that originated from West Africa. Palm oil has centuries? long use as food and medicine. This review covers the recent significant materials found in the literature on palm oil processing, refining, and use in frying especially in blends with other vegetable oils.

A Comprehensive Guide to the Palm Oil Production Process

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, small production machinery in oil press

- Production Capacity: 250-400 kg/h

- Voltage: According to customer demand

- Power(W): 21 KW

- Dimension(L*W*H): 2200*1600*2150

- Weight: 1300kg

- Color: White, green

- Production Material: Carbon steel, stainless steel

- Raw material: Palm

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical extruding

- Warranty period: One year

- Factory visiting: Yes

The refining process is like giving it a spa treatment. Crude palm oil, as the name suggests, isn't perfect yet. It contains some things we don't want, like impurities and odors. That's where refining comes in. Hence, in the second stage of palm oil process, we discuss refinery process of crude palm oil. Refinery of Crude Palm Oil

step in the oil extraction process has been explained, it will be possible to apply the criteria for the selection of equipment required to meet the processor’s needs and investment potential. A by-product of palm oil extraction is the palm nut which, when cracked, yields a kernel

Palm Oil Milling & Processing Handbook

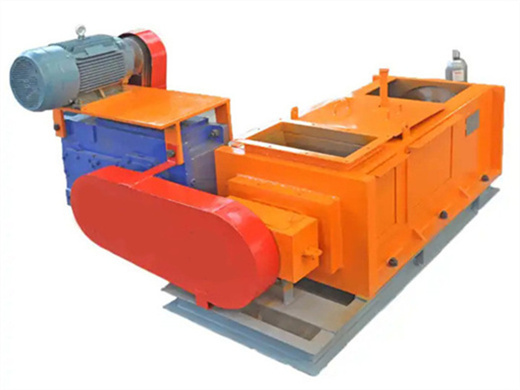

- Usage: Palm Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 50-1000kg/h

- Voltage: 220/380

- Dimension(L*W*H): 1400*860*1260

- Weight: 280 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Other, Gear, Bearing, Engine, Gearbox

- Oil type: Palm Oil

- Product name: Oli Press Machine

- Function: Making Edible Oil

- Application: Screw Oil Expeller

- Raw material: Palm

- Advantage: Energy Saving

- Material: 304 Stainless Steel

- Color: Customer Required

- Capacity: 750kg/h

The Roundtable on Sustainable Palm Oil (RSPO) is a non-government certification initiative by members of the palm oil industry with, inter alia, the aim of mitigating environmental impacts by.

Oil is an indispensable ingredient in our daily lives. From using it in food to its application in the manufacturing of cosmetics and as a renewable resource for bio-diesel fuel production, oil is one of the most important commodities in the market currently. Just like its different applications, the methods of oil extraction are also

threshing in palm oil production process

- Usage: Palm Oil

- Production Capacity: 98%-100%

- Voltage: 380V/

- Power(W): 5.5~18.5KW

- Dimension(L*W*H): 1950*1300*1900, according to the capacity

- Weight: 950KG

- Raw material: Palm

- Application: Oil Pressing

- Common capacity: 80-600kg/h

- Warranty: One Year

- Character: Screw Oil Pressing Machines

- decoloring time: 15-20min

- Moisture: 3%

- residual oil in cake: 2%

In palm oil production process, threshing is the second process. Threshing is to separate the palm fruit and bunches, and then make the palm fruit continue to be processed in the whole line. Next is the working process video of palm fruit threshing drum in palm oil production process. You can watch it to learn about the details.

Palm Oil Processing Machine Palm Oil Press Machine On Sale

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, Palm Oil Refinery Mill

- Production Capacity: 30-500TPD Palm Oil Refinery Mill

- Voltage: 380V

- Power: 2.2KW

- Dimension(L*W*H): 1910*550*765 mm

- Weight: Based on Palm Oil Refinery Mill capacity

- Raw material: Palm

- Cooking Oil Machinery Process: Pre-treatment,Solvent Extraction,Refining

- Solvent Extraction Process: DTDC,Miscella Toasting and Stripping,Solvent Collecting,etc

- Pretreatment Process: Cleaning,Hulling,Breaking,Soften,Flaking,Puffing,Toasting

- Service: Engineer Abroad Erection

- Refining Process: Degumming,Deacidification,Deordorization,Decoloration,etc

- Process Capacity: 500TPD Palm Oil Refinery Mill

- Packing: Frame and Container

1 General processing description. Research and development work in many disciplines biochemistry, chemical and mechanical engineering and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a.

- How is palm oil extracted?

- Palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. Palm oil extracting plant generally begins with the harvesting of the fruit. This is the process of palm oil physical extracting (screw pressing) and field factors that determine quality of expelled palm oil.

- What is palm kernel oil extraction process?

- PALM KERNEL OIL EXTRACTION Mechanical extraction processes are suitable for both small- and large- capacity operations. The three basic steps in these processes are (a) kernel pre-treatment, (b) screw-pressing, and (c) oil clarification. Diagram 2: Mechanical extraction of palm kernel oil.

- How to extract Palm oil from fruit?

- This is the process of palm oil physical extracting (screw pressing) and field factors that determine quality of expelled palm oil. For extracting oil from palm fruits, you will have to start by harvesting fresh fruit bunches and keeping them ready for the next stage of palm oil production.

- What is palm oil processing?

- The kernel processors have to go around the palm oil processors during the peak season, when prices are lowest, to purchase the nuts for drying. The nut processing and oil extraction is undertaken in the dry season when the pressure to obtain raw materials has subsided. The traditional palm oil processing starts with the shelling of the palm nuts.

- What equipment is used to extract Palm oil?

- Sterilizer, Thresher, palm oil expeller, clarification equipment, palm nut polishing machine. Palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. Palm oil extracting plant generally begins with the harvesting of the fruit.

- What is a palm oil production column?

- The Palm Oil Production Column will introduce the details of each process, providing you with the guidance and support you need for your palm oil business. Palm oil production is a complex process that involves a variety of stages, each of which is critical to the success of the overall operation.