The ultimate guide to the palm oil production process

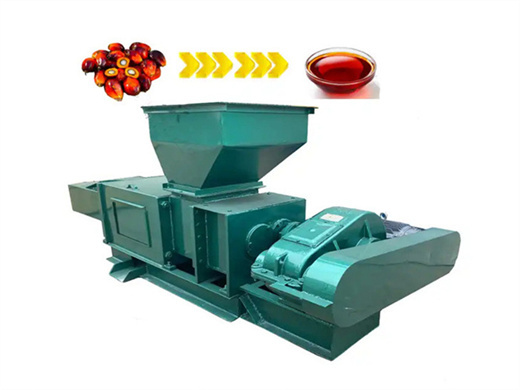

- Usage: Palm OIL

- Production Capacity: 98---100%

- Voltage: 380v

- Dimension(L*W*H): 2600*1890*3000mm

- Weight: 1600 KG

- Warranty: 1 Year

- Key Selling Points: Long Service Life

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Other, Gear, Bearing, Engine, Gearbox

- Product name: vegetable oil/Palm oil production line

- Application: Palm Oil Production

- Function: Oil Pressing Palm

- Capacity: 230kg/h

- Used for: Palm Oil Making Plant

- Quality: High Level

- Color: Silver

- Character: Screw Automatic Extrator

- MOQ: 1 Set

Time for palm oil extraction machines. PALM OIL EXTRACTION. Now we come to the central step in the palm oil production process: extraction. Separated palm fruits are processed to extract crude palm oil. Fibres and the palm kernel get left behind. There are two commonly used methods for palm oil extraction. Approach 1: wet method.

The Palm Oil Production Column will introduce the details of each process, providing you with the guidance and support you need for your palm oil business. Unveiling Palm Oil Production Process Steps Refining Process-Starting a Palm Oil Refining Plant Cost

Palm Oil Press Machine Palm Kernel Oil Extraction Machine

- Usage: Palm Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 45 kg per hour

- Voltage: 220-240 volt

- Dimension(L*W*H): 840 *240 *540 mm

- Weight: 67 KG

- Warranty: 2 years

- Warranty of core components: 2 years

- Core Components: Motor, Gear, Bearing, Gearbox, motor driver

- Oil type: Palm Oil

- Thermostat: Temperature Control 600 Watt

- Motor Power: 1,5 kW

- Raw material: STAINLESS STEEL

- After-sales Service Provided: Video technical support

Palm oil is an oil with a high oil content, about 46-50%, and can be easily squeezed to produce oil. Better quality palm oil can be obtained through refining and fractionation. The first process of palm oil extraction begins at the palm oil extract plant, where fresh palm fruit bunches are received and processed.

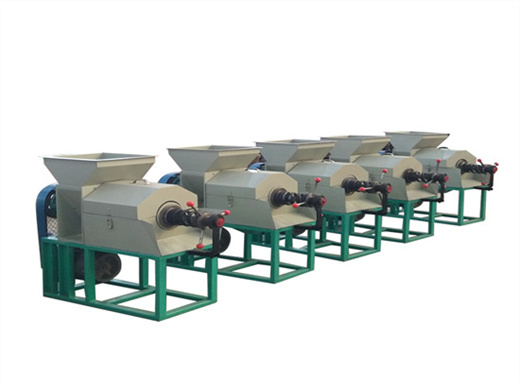

In addition to medium and large palm oil extraction plant, we can also customize different daily processing capacity of small scale palm oil production lines for small business, such as: 1 ton/hour, 2 tons/hour, 3 tons/hour, 5 tons/hour, etc. Small scale palm oil extraction plant include six steps: threshing, sterilization, digestion, pressing, crude oil clarification and filtration, all.

costs involved in setting up a palm oil mill

- Usage: Palm Oil

- Type: Automatic Palm Fruit Oil Processing Machine

- Production Capacity: 4-20kg/h

- Voltage: 110v/220v

- Dimension(L*W*H): 460*180*290mm

- Weight: 13 KG

- Warranty: 1 Year

- Key Selling Points: Low Noise Level

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Pressure vessel, Bearing, Engine

- Keywords: Automatic Oil Press Machine

- Production: 4-20kg/h

- Voltage/Frequency: 220V,50Hz/110V,60Hz

- Material: Brushed Stainless Steel

- Wide Application1: Palms

- Wide Application2: pumpkin seeds,eans,Palm

- Wide Application3: Palm,hazelnut kernels, Palm Kernels

- Driven Way: Electric Motor

- WhatsApp/WeChat/Mobile: 0086 18903714772

- Package: Special Tailored Wooden Case for Package

In addition, we also need to have enough space for palm oil processing, storage and office facilities for staff. The palm oil mill construction cost will vary depending on the location of the palm oil mill, its size, and whether a new building is needed or whether an existing building can be renovated. The picture of setting up a palm oil mill. 2.

Palm nuts are very valuable because they can be used to create three raw products palm kernel oil (Palm Kernel Oil Extraction Machine), dry cakes made of mesocarp fibre, and palm kernel shells. The three main by-products from the process of extracting oil from palm kernels are the Empty Fruit Bunches (EFB), the Palm Kernel Shell (PKS), and.

PALM OIL PROCESSING Palm Oil Mill Machine Leading

- Usage: Palm Oil, Cooking Oil

- Type: Cold & Hot Pressing Machine, Screw Press

- Production Capacity: High

- Voltage: 380V/440V

- Dimension(L*W*H): Customised

- Weight: 0 KG

- Warranty: One Year warranty against manufacturer defect.

- Warranty of core components: Other

- Core Components: Other

- Oil type: Palm Oil

- Raw material: Crude Vegetable Oil

- Function: Making Edible Oil

- Application: Edible Oil Production

- Feature: High Oil Yield Efficiency

- Complete Warranty Service: Video technical support

- Post sales Warranty Service: Spare parts

- On site Warranty Service: Field maintenance and repair service

3. 1 General processing description. Research and development work in many disciplines biochemistry, chemical and mechanical engineering and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a high yield of a.

Local and Modern Methods of Crude Palm Oil Extraction

- Usage: Palm OIL

- Type: Automatic Palm Fruit Oil Processing Machine

- Production Capacity: 800KG/H

- Voltage: 380V/50HZ

- Dimension(L*W*H): 2670*1000*1726mm

- Weight: 1800 KG

- Warranty: 1 Year

- Key Selling Points: Long Service Life

- Machinery Test Report: Not Available

- Video outgoing-inspection: Not Available

- Warranty of core components: 1 Year

- Core Components: Gearbox

- Product name: YZYX168 Screw Oil Press Machine

- Company character: manufacturer with export right

- Color: Blue,Yellow,Sliver

- Capacity: 800kgs/h

- Raw material: Palm Kernel

- Oil content of dry cakes: <=7.6%

- Spiral axes rotate speed(r/min): 36-44

- Advantage: Simple Operation/high efficiency

- Application: Screw Oil Expeller

- Material: Carbon Steel Q235

The secondary crude palm oil extract is obtained by further processing palm oil milling residues, such as palm oil mill effluent (POME), fiber, and pressed chaff. It involves recovering residual oil trapped in these by-products, typically through mechanical pressing, decantation, or solvent extraction.

- What is the palm oil processing plant project report 2025?

- IMARC Group’s report titled “Palm Oil Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a palm oil processing plant.

- How a palm processing unit will increase palm oil production in India?

- October 204: Patanjali is set to establish a palm processing unit in Tripura, aiming to increase the local economy by enhancing palm oil production. March 2024: 3F Oil Palm launched India's first integrated oil palm processing unit, marking a significant step in the to increase domestic palm oil production in the country.

- How does government support palm oil production?

- By providing financial assistance, governing agencies are encouraging farmers to increase production, ensuring a stable supply. Palm oil production is also supported through tax incentives, which reduce operational costs for businesses.

- What are the analysis and analysis of palm oil processing plant costs?

- This includes the analysis and detailed understanding of palm oil processing plant costs, including capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

- How AI is transforming Malaysia's palm oil industry?

- November 2024: Malaysia launched its first palm oil mill incorporating artificial intelligence (AI) to enhance efficiency and sustainability. This initiative leverages AI technology to optimize operations, reduce waste, and improve production quality, aligning with Malaysia's efforts to modernize its palm oil industry.

- Why is 3F oil palm launching India's first integrated oil palm processing unit?

- March 2024: 3F Oil Palm launched India's first integrated oil palm processing unit, marking a significant step in the to increase domestic palm oil production in the country. The facility will help strengthen India’s edible oil supply chain and reduce dependency on imports.