Horizontal sterilizer, vertical sterilizer and tilting sterilizer

- Usage: Palm Oil

- Production Capacity: 10 Tons / Day

- Voltage: 30HP

- Dimension(L*W*H): 2641MM*1016MM*2489MM

- Weight: 5500 KG

- Warranty: 1 Year

- Key Selling Points: Energy saving

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 5 years

- Core Components: Motor, Bearing, Gearbox

- After-sales Service Provided: Engineers available to service machinery overseas

- Extraction of Oilseeds: Palm ,Palm,Maize ,Palm Kernel ,Palm

- MOTOR: 30 HP

- CAPACITY: 10 Tons/Day

The following discussion on the different types of sterilizer: Horizontal Sterilizer The horizontal sterilizer is the most commonly used sterilizer in palm oil mills.When disposed in a horizontal position, the cylindrical vessel sterilizer has fairly good disposition because the oil palm fresh fruit bunches placed in cages with a low stacking height are more uniformly spread out in this.

Best Steel Berhad is redefining the future of palm oil milling processes by introducing latest technology in sterilization known as the Tilting Sterilizer?, a patented design by Best Steel. Its operation and performance have been successfully proven with a fresh fruit bunch (FFB) filling capacity of 15 to 30 t per charge and a throughput of 10.

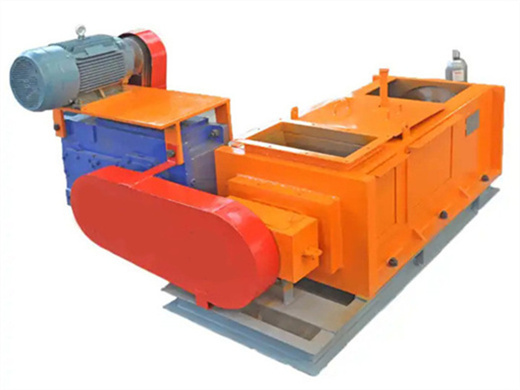

Offer BEST Palm Oil Machinery with Reasonable Price

- Usage: Palm Oil

- Type: Vegetable Oil Processing Equipment

- Production Capacity: 150-200KG/H,3.5-5T/24H

- Voltage: 380V/220V

- Dimension(L*W*H): 1900*1300*2000mm

- Weight: 9100kg

- Warranty of core components: 2 years

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Other

- Oil type: Palm Oil

- Product name: Oil Press Machine

- Function: Oil Pressing

- Feature: Automatic Machine

- Key words: Cooking Oil Making Machine Palm

- Application: Squeeze Oil

- machine material: Carbol Steel

- Raw material: Palm

- Advantage: High Oil Yield

- Capacity: 3.5-12TPD

Palm Oil Mill Plant Design. Alll the projects we build for our customers are designed depanding on their specific situation, requirements and cost budget. If you are keen in buying palm oil machines or building a palm oil mill plant, don't hesitate to inquiry about the details or cost! We are always at your service 7x24 hours!

5tph palm oil processing machines project successfully installed in Liberia. 1tph palm oil pressing plants project successfully installed in Uganda, Nigeria. 5tph palm kernel cracker and separator machine project and 1tph palm kernel oil making machine project in Uganda. 2tpd batch type cooking oil refinery plant project in China

Effect of different sterilization methods on the extracted

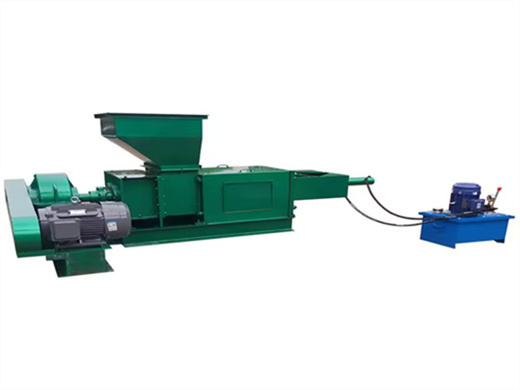

- Usage: Palm Oil, Cooking Oil

- Production Capacity: 10TPD-100TPD

- Voltage: 380v

- Dimension(L*W*H): See the detailed information

- Weight: 1000 KG

- Core Components: Motor, Pressure vessel, Pump, PLC, Other, Gear, Bearing, Engine, Gearbox, Complete Palm Oil Production Line

- Oil type: Palm Oil, Complete Palm Oil Production Line

- Raw material: Palm

- Product name: Complete Palm Oil Production Line

- Function: Making Edible Oil

- Material: Stainess Steel

- Advantage: High Oil Yield

- Capacity: 10-300tpd

- Package: Wooden Case

- Quality: High Level

- Brand: Huatai

Horizontal-sterilizer is the most commonly used sterilizer in palm oil mill palnt.When disposed in a horizontal position, the cylindrical vessel sterilizer has fairly good disposition because the oil palm fresh fruit bunches placed in cages with a low stacking height are more uniformly spread out in this position across the length of the.

Description. The sterilizer is made up of fruit, water and fire chambers. It is used to sterilize fruits under atmospheric conditions in order to inactivate oil-splitting enzyme (lipase), soften the mesocarp for easy digestion, facilitate the release of oil during digestion stage, coagulate nitrogenous and mucilaginous substances so as to prevent formation of emulsions in crude palm oil during.

Vertical Palm Fruit Sterilizer SUMPOT Retort

- Usage: Palm Oil

- Production Capacity: 98%-100%

- Voltage: 380V/

- Power(W): 5.5~18.5KW

- Dimension(L*W*H): 1950*1300*1900, according to the capacity

- Weight: 950KG

- Raw material: Palm

- Application: Oil Pressing

- Common capacity: 80-600kg/h

- Warranty: One Year

- Character: Screw Oil Pressing Machines

- decoloring time: 15-20min

- Moisture: 3%

- residual oil in cake: 2%

Description This palm fruit sterilizer uses high-pressure steam to loosen the nuts and make them expand in the moisture. Thissterilization process softens the fruit bunch, reducing the amount of water released while preserving the quality of thefruit. when the pressure is lowered, the stem is more easilu separated from the pulp, ensurina that the nuts pass thesterilization process with minimal.

Vertical Sterilizer For Palm Oil Mill

- Usage: Palm Oil

- Production Capacity: 45 sets per year

- Voltage: 380V/440V

- Power(W): 30KW

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 500TON

- usage: automatic Palm oil making machine

- oil clolor: yellow

- advantage: save energy

- bleaching earth consumption: 5-50kg/t oil

- decolor function: remove the bad color

- deodor function: remove the bad smell

- Function: automatic Palm oil making machine

High-Productivity Design: Our Vertical Sterilizer For Palm Oil Mill boasts a high productivity design, ensuring efficient processing of palm fruits. This is particularly beneficial for large-scale manufacturing plants and farms looking to increase their output.

- Why is palm oil sterilization important?

- This palm fruit sterilization step in the palm oil extraction process is crucial to the final oil quality as well as the strippability of fruits. Sterilization inactivates the lipases in the fruits and prevents buildup of free fatty acids (FFA). In addition, steam sterilization of the FFBs facilitates fruits being stripped from the bunches.

- How a palm oil mill is sterilized?

- Conventionally, in a palm oil mill plant the sterilization process is carried out in cylindrical pressure vessels, lying in horizontal or vertical position, and filled with steam under pressure as a batch process.

- What are the different types of sterilizer in palm oil mill?

- Manufacturing Horizontal sterilizer, vertical sterilizer and tilting sterilizer,Sterilization is one of the key processes in any palm oil mill.For the production of palm oil, there are three types sterilizer for customer to choose: Horizontal sterilizer, vertical sterilizer and tilting sterilizer.

- Why is steam sterilization important in palm oil mill?

- In addition, steam sterilization of the FFBs facilitates fruits being stripped from the bunches. It also softens the fruit mesocarp for digestion and release of oil, and conditions nuts to minimize kernel breakage. Main stations in palm oil mill plant

- What is avatar technology in palm oil extraction?

- 2. Share with us how Avatar Technology or known as dynamic sterilization, for the extraction of crude palm oil helps the work environment, sustainability, and profitability. The advantages of using Avatar Technology in palm oil extraction over traditional systems are manifold.

- How can palm oil processing plants be automated?

- Automation in Processing Plants Processing palm oil fruits involves several stages traditionally reliant on manual labor, prone to being slow and error prone. GAPKI is implementing automated conveyor systems to streamline the transport of fruits within processing plants.