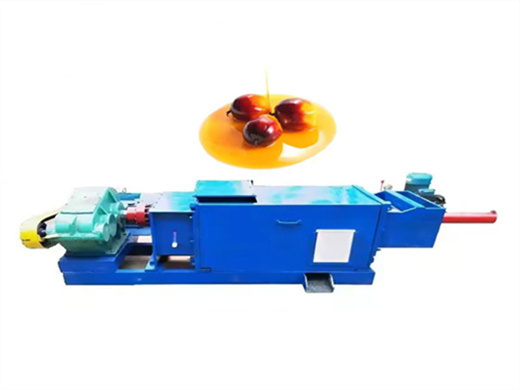

Small Scale Palm Oil Mill Plant, Equipment for 1-20t/d Production Line

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, Palm oil mill project

- Production Capacity: 98%-100%

- Voltage: 380

- Power(W): 2.2KW

- Dimension(L*W*H): 1050*950*1650

- Weight: 550kg

- Raw material: Palm

- Capacity: 450-7000kg/h

- Advantage: Easy Operation

- Application: Oil Pressing

- Customers: China/America/Europe/Africa/Asia

- Oil standard from it: high purity crude oil

Features of Our Small Palm Oil Mill Plant Save manpower. Less investment but with full extraction function. Easy to install and operate. Process Design of Small Palm Oil Factory. If you are planning to run a small palm oil making factory, here is the factory layout design for your reference: Small Crude Palm Oil Milling Plant Design

The cooking or steaming can be done using specialized equipment. 6. Oil Extraction with Expeller Press: The cooked palm kernels are then fed into a palm kernel oil press or expeller. The expeller applies mechanical pressure to squeeze the oil out of the palm kernels. This process separates the oil from the solids, resulting in crude palm kernel.

DESIGN AND FABRICATION OF A PORTABLE PALM KERNEL EXTRACTOR

- Usage: Palm Oil

- Type: whole red Palm oil machine

- Production Capacity: 100%

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): various with capacity

- Weight: changed with capacity

- Raw material: Palm

- Product: to make crude Palm oil or refined Palm oil

- Solvent name: n-hexane

- Capacity: from 5T to 2000T red Palm oil machine

- Oil content in Palm: about 40%

- Oil residues: less than 1%

- Function: getting Palm oil

- Manufacturing experience: 19 years experience in edible oil field

- Material of equipment: stainless steel and carbon steel

Is to design and fabricate a portable palm kernel oil extraction plant that willproduce 100kg-200kg of palm kernel oil per day using palm kernel and to reducewaste and improve the efficiency and output of palm kernel. This can only be * achieved by mechanizing the palm kernel oil extraction processes over the manual process of

Palm oil extraction process: Palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. Palm oil extracting plant generally begins with the harvesting of the fruit. This is the process of palm oil physical extracting (screw pressing) and field factors that determine.

How many tons palm fruit are needed to produce 1 ton of palm oil

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, batch solvent extraction plant

- Production Capacity: 100%

- Voltage: Local Voltage

- Power(W): Capacity

- Dimension(L*W*H): 1700*1100*1600mm

- Weight: 1100kg

- Application: Oil Pressing and production line

- Machine output: according to you need

- Character: Semi-auto and automatic

- Item: Edible Oil Press

- Advantage: Energy Saving

- Warranty: Long Term Technical Support

- Package: Wooden Case

- Price: Cost Effective

- Quality: China Top

However, this is only a theoretical calculation method. Actually, the oil yield of palm oil can also be influenced by many other factors, such as the variety of oil palm fruit, oil content of oil palm fruit, the palm oil extraction technology and the degree of automation. Next, Henan Glory will introduce them in details for you. 1.

It is a device that squeegee the oil in palm kernel by pressing the screw continuously. The palm kernel oil press is a palm kernel oil press equipment specially designed by Henan Guorui Engineering Technology Co., Ltd. according to the characteristics of palm kernel. It is easy to operate, easy to maintain and has a high degree of automation.

Palm oil mill process flow diagram introduction

- Usage: Palm oil refinery

- Automatic Grade: Semi-Automatic

- Production Capacity: 200t-2000t per day

- Voltage: as requirement

- Power(W): according to capacity

- Dimension(L*W*H): 1200*400*900mm3

- Steam consumption:

- Electric Power consumption:

- Water consumption:

- Citric acid:

- Caustic soda:

- Bleaching Earth consumption:

- Residue Oil content in Waste clay:

- Water circulation:

The above is the mainly introduction of palm oil mill (suitable for capacity above 15tph). Any question about palm oil mill process flow chart diagram and any capacity palm oil processing machine, please feel free to contact Henan Doing Company. You will get more thank you think.

Development of a manually operated palm oil extraction machine

- Usage: Palm Oil, Cooking Oil

- Type: Cooking Oil Press Machine

- Production Capacity: 5TPD-100TPD

- Voltage: 220V

- Power: 5.5kw

- Dimension(L*W*H): 40*21*58 cm

- Weight: 45 kg, 45 kg

- capacity: 30kg/hour

- voltage: 220v/50hz

- material: SS304

- Press type: Low temperature press

- Control type: Automatic microscope

- size: 40*21*58 cm

- product name: Grape Oil Press Machine/oil crushing machine on sale

method to extract palm oil. Both the methods are not suitable for extraction of high quality palm oil. It is done for small-scale purpose. Ikechukwu (2012) stated et al. that the mechanical extraction method uses screw press as the principal means of extracting vegetable oil. However, use of the screw press for full extraction has been

- How to start a palm oil processing plant in Indonesia?

- Establishing a palm oil processing plant in Indonesia is a lucrative opportunity, and a careful understanding of the associated costs is key to success. Key steps include the cost of acquiring suitable land, infrastructure costs, processing machinery costs, and various management and operational costs. Plant Layout and Design:

- Do Indonesian smallholder oil palm plantations yield more than corporate plantations?

- Indonesian smallholder oil palm generally yield much less than corporate plantations. We analysed a smallholder oil palm production system in West Sumatra which outperformed its nucleus estate plantation, consistently producing yields far above the national average for over 25 years.

- Should oil palm smallholders be certified in Indonesia?

- In the near future, certification for oil palm smallholders will be mandatory in Indonesia. Sustainability certification includes attention for using best management practices, socio-economic development and decision rights for smallholders.

- How much does a palm oil plant cost?

- A small palm oil mill plant may cost around US70,000, while a large palm oil manufacturing plant may cost more than $1 million. At ABC Machinery, we are committed to providing you with superior palm oil processing solutions that are designed to achieve optimum production efficiency through customized process flows and plant layouts.

- Can palm oil plantation waste be used for house building materials?

- Natural Fiber Waste from Palm Oil Tree: An Overview of Potential Usage for Indonesia's Affordable House Building Materials The palm oil plantation in Indonesia is an overgrowing industry that also poses significant environmental waste problems.

- How to invest in palm oil processing mills in Indonesia?

- In the business of investing in palm oil processing mills in Indonesia, site selection is a crucial decision. Choosing the right location not only directly affects the factory construction process and the size of the investment, but also has a profound impact on the local economy, environment, agriculture and society.