Palm Oil Mill Processing Machines Palm Oil Mill Machine

- Usage: Palm oil solvent extraction

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 22kw/h

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 40tons

- Capacity: 10-500tpd

- Application: Palm oil solvent extraction

- Oil rate: 18-22%

- Processing capacity: 20tpd to 200tpd

- Steam consumption: ≤280Kg/T (0.8MPa)

- Power consumption: ≤ 15KWh/T

- Solvent consumption: ≤3Kg/T(6#solvent oil)

- Residual oil in meal: ≤1%

- Residual solvent in finished meal: ≤ 300PPM (qualified detonated experiment )

8.Palm oil mil process of clarification: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. The oil and the sludge taken out separated (by 90% pure oil) is taken out.

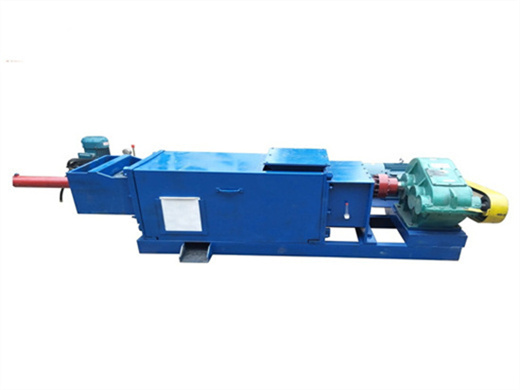

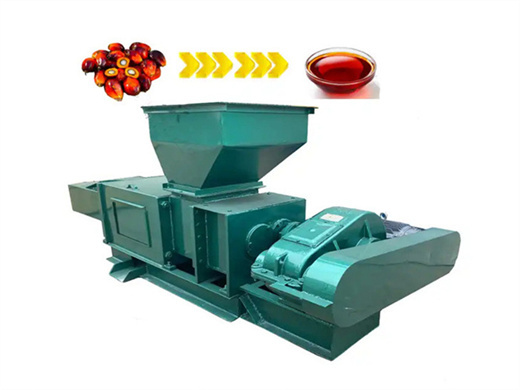

1. Palm kernel oil pressing machine: Next, in the palm kernel oil extraction unit, the roasted palm kernels are transported to the palm kernel oil press machines, where the palm kernels are continuously squeezed by the pressing screw to squeeze out the oil. After pressing, we can get crude palm kernel oil and pressed cake.

PALM OIL MILL MACHINE

- Usage: Palm oil

- Production Capacity: 10-300T/D

- Voltage: 380V /440V or the local voltage

- Power(W): 30kw

- Dimension(L*W*H): 120*45*12m

- Weight: single 5000KG

- Key word: mini Palm oil mill plant

- Supplier type: Factory(more than 35 years experience)

- Capacity: 10-300T/D

- Materials: Carbon steel Q235 and stainless steel SS304/316

- Services: Three-D design and turnkey project

- After-sale services: Installation, debugging,trainning your workers

- Oil residues: Less than 1%

- Advantage: Professional engineer team in oil mill plant design

Type: palm fruit/bench oil pressing, making machines Processing Material: Palm fruit Processing Capacity: 5-120TPH . Palm Oil Mill Plant Flow Chart Introduction: 1.Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge.

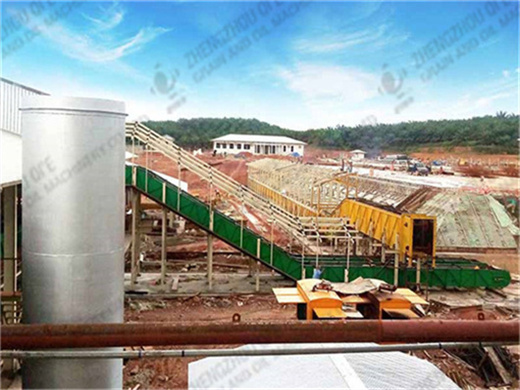

1tph palm oil processing mill plant project in Nigeria. Liberia 2TPH palm kernel oil processing plant project case. 30tpd palm oil refinery and fractionation plant project in Uganda. Palm kernel cracker and shell separator machine successfully installed in Sierra Leone

machines used for palm oil processing

- Usage: Palm Oil

- Production Capacity: 100%

- Voltage: 380V/440V or required

- Dimension(L*W*H): 3740*1920*3843 mm, 3740*1920*3843 mm

- Weight: 9160 KG, 9160kg

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Marketing Type: Ordinary Product

- Machinery Test Report: Not Available

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Other

- Application: Oil Production Line

- Item: Industrial Oil Extractor

- Function: Making Palm Oil

- Advantage: High Oil Yield

- Raw material: Palm Kernel

- Color: Optional

- Material: Stainless Steel/Carbon Steel

5. press: the major function of screw palm oil press machine is to extract palm oil from palm fruit. As for different palm oil processing capacity, there two kinds of screw palm oil press machine for people to choose, one is screw palm oil press machine, the other is double screw palm oil press machine. Screw palm oil press machine. 6.

8.Palm oil mil process of clarification:Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. The oil and the sludge taken out separated (by 90% pure oil) is taken out.

Palm oil milling equipment and machinery | Alfa Laval

- Usage: Palm oil press equipment

- Type: Vegetable Oil Machine

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 22kw/h

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 40tons

- Capacity: 10-500tpd

- Application: Palm

- Oil rate: 18-22%

- Processing capacity: 20tpd to 200tpd

- Steam consumption: ≤280Kg/T (0.8MPa)

- Power consumption: ≤ 15KWh/T

- Solvent consumption: ≤3Kg/T(6#solvent oil)

- Residual oil in meal: ≤1%

- Residual solvent in finished meal: ≤ 300PPM (qualified detonated experiment )

For decades, Alfa Laval has worked closely with palm oil mills in the development of reliable, efficient solutions for converting palm fruit into crude oil. Today our palm oil milling equipment can be found throughout the oil room. Designed with over a century of separation technology expertise, we offer state-of-the-art decanter and disc stack centrifuges optimized for mills, as well as.

Palm oil Fraction plant machine Lingfine Machinery

- Usage: Palm Oil

- Type: Automatic Palm Fruit Oil Processing Machine

- Production Capacity: 50-60 kg/h

- Voltage: 220V/380V

- Dimension(L*W*H): 1450*870*1190 mm

- Weight: 320 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Item: screw oil press machine

- Capacity: 50-60 kg/h

- Use: Extract oil

- Raw material: Palm Kernel

- Function: Cold&hot oil press

- Advantage: Simple Operation

- Material: Carbon Steel

- Application: Industrial oil press

Oil fractionation introduction: Palm oil fractionation technology adopts advanced palm oil processing technology of controlled cooling, crystallization, filtration and separation technology, obtaining palm oil with different melting points, like 33℃, 24℃, 18℃, 14 ℃,12℃,10℃,8℃,etc.

- Which machine is required for palm kernel oil processing?

- Palm Kernel Shell Separation System: the fiber separation machine is the machine required for the first step of palm kernel oil processing. Magnetic separators are used to remove metal debris; vibrating screens are used to remove stones and sand. Plam kernel cracker and separator machine 8.

- What is palm oil extraction?

- Extraction of oil from the palm kernels is generally separate from palm oil extraction, and will often be carried out in mills that process other oilseeds (such as groundnuts, rapeseed, cottonseed, shea nuts or copra).

- What is a kernel recovery section of palm oil processing?

- 8. Kernel Recovery Section of palm oil processing: the separated husks are sent to the warehouse for temporary storage, and used as fuel for the boiler room when necessary; the dried kernels are sent to the kernel storage for storage, and a palm kernel pressing production line can also be configured if necessary.

- Where can I find palm oil milling equipment?

- Today our palm oil milling equipment can be found throughout the oil room. Designed with over a century of separation technology expertise, we offer state-of-the-art decanter and disc stack centrifuges optimized for mills, as well as dryers, pumps and much more. Discover how we can help you maximize yield and profitability.

- How do palm oil processing machines work?

- Palm oil processing machines 1. Fruit Reception: It is used for temporary storage and unloading fresh palm fruit bunches from palm plantation. Fruit reception 2. Sterilizer: three types of sterilizers can be chosen in palm oil processing. All use high temperature of 145°C to soften and sterilize the fruit bunches.

- What types of palm oil processing lines can Henan Glory company provide?

- Henan Glory Company can provide three types of palm oil processing lines and machines used for them, from simple type to large scale.