large capacity palm oil refinery process flow in mali

- Usage: Palm Oil

- Type: oil refine

- Production Capacity: 100%

- Voltage: 380V,440V

- Power(W): 7.5kw/h-25kw/h

- Dimension(L*W*H): depend on the capacity

- Weight: according to capacity

- Product name: High quality Palm oil refinery

- Capacity: 1-1000TPD

- Material: Palm, flax, Palm , suzi, Palm

- Function: refine Palm oil

- Steam consumption: 450kg/T oil

- Phosphoric acid: 2~3 kg/T Oil

- Bleaching earth consumption: 5~50Kg/Toil

- Dodorization loss: ≤0.5%

- Waste bleaching earth oil content: <35%

- Manufacturing experience: 37 years

Palm Oil Processing Palm Kernel Oil Production Line. Palm oil processing starts with the fresh fruit bunches of the oil palm, which are pressed, refined, and fractionated to produce palm oil. [email protected] 0086-159-3728-9608 0086-159-3728-9608 Home . The process of crude oil refining.

Mainly through heating and steaming and frying, the palm kernel can achieve good oil production conditions, so that more high-quality palm kernel oil can be obtained; (6) Palm Kernel Oil Press Equipment: The palm kernel oil press is the same as the conventional oil press and can be used in general. Through pressing, we can get crude palm kernel.

Palm kernel oil extraction machine, Palm Oil Production Line

- Usage: Palm Oil

- Production Capacity: 100%

- Voltage: 220V/380V/440V

- Dimension(L*W*H): 1400*600*600mm

- Weight: 1100 KG

- Warranty: 2 years

- Key Selling Points: Famous brand motor

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel

- After-sales Service Provided: Engineers available to service machinery overseas

- Feed stock: FFB fresh palm fruit bunch

- Color: up to buyer

- Application: palm oil milling machine

- Advantage: Energy Saving

- Function: palm oil processing machine

- Material: Steel

- Product name: palm oil milling machine

- Application range: Palm Fruit Bunch

Type: Palm Kernel Oil Extraction. Processing material: Palm Kernel. Capacity: 20-1000T/D. Palm Kernel Oil Extraction Equipment: Crusher, Dryer, Oil Expeller. Application: High Efficiency Crude Oil Pressing & Extracting From Palm Kernel With Low Oil Residual. Palm Kernel Oil Solvent Extraction Plant is recommended for large Palm Kernel Oil Mill.

But palm kernel oil solvent extraction workshop is built on the basis of having palm kernel oil press production line. Palm kernel oil solvent extraction workshop is using solvent to extract oil from palm kernel cake, finally the oil residue inside meal is less than 1%. And dry meal can be used for animal feed.

High Quality Palm Oil Production Line For Big Capacity

- Usage: Palm oil production machine

- Type: Palm oil production machine, Palm oil production machine

- Production Capacity: According to your capacity

- Voltage: Match with local voltage

- Power(W): Capacity

- Dimension(L*W*H): 1610x615x1260mm of Palm oil production machine

- Weight: 1050 KG of Palm oil production machine

- Controlled: PLC

- PLC Use range: All kinds of vegetable s

- Solvent: X-hexane

- Capacity: According to your require

- Advantages: Suitable for many materials

- Residual oil: 1%

- Materials: Q304R & SS steel

- Color: According to your request

The Batch type is the ideal choice for small-sized palm oil production (1-20TPD), while the Semi-continuous Refinery plants are the best choices for middle-large size production lines (20-50TPD), a fully continuous refinery line(50-600TPD) is most used in large palm oil production plants.

Our Oil Machinery is a leading company in the field of palm oil pressing and palm kernel oil processing and equipment, we can provide completely set of 5-120tph palm oil production line. Our company offers a range of products and services for the palm oil extraction, palm kernel oil extraction, crude palm oil refining and complete palm oil.

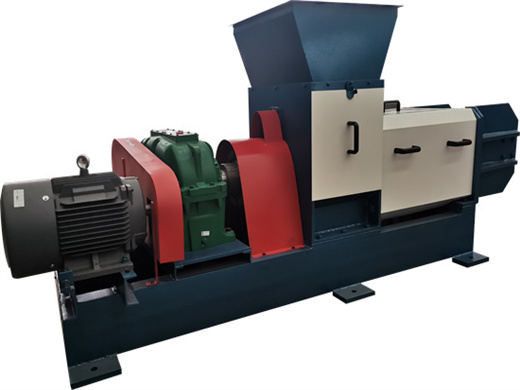

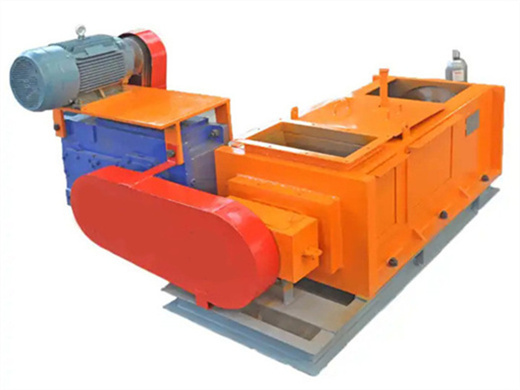

6YL-130 Palm Kernel Oil Line BTMA Palm Kernel Oil Press

- Usage: Palm Oil

- Production Capacity: 30-450kg/h

- Voltage: 3880V

- Dimension(L*W*H): 1800*1300*1680

- Weight: 1000kg

- Warranty: 1 Year, 12 Months

- Key Selling Points: Sustainable

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Raw material: Palm Kernel

- Function: Oil Pressing

- Application: Oil Production Line

- Capacity: 30-450kg/h

- Color: Customer Required

- Press type: Hot Press Oil Machine

- Advantage: Simple Operation

- Package: Wooden Case

- Local Service Location: None

- After-sales Service Provided: Video technical support, Online support

1. Model: gz-1 2. Capacity: 1t/h 3.Power: 3Kw/380V 4. Weight: 1200kg 5. Function: The palm fruit digester machine plays a crucial role in the palm oil extraction process. It effectively breaks down the palm fruit into a pulp, facilitating the release of oil during pressing.

Palm Kernel Oil Production Line Edible Oil Production Machine

- Usage: Palm Oil

- Type: Cold & Hot Pressing Machine, vegetable ghee making machine

- Production Capacity: 1TPD-500TPD

- Voltage: According to customer demand

- Power(W): According to project

- Dimension(L*W*H): According to project

- Weight: According to customer demand

- Color: According to customer demand

- Production Material: Carbon steel, stainless steel

- Raw material: Palm

- Export markets: Europe, Southeast Asia, Africa, etc

- Work principle: Mechanical principle

- Warranty period: One year

- Factory visiting: Yes

The Oil Extraction for Palm Kernel mainly include 2 methods, Mechanical extaction and Solvent extraction.Mechanical extraction processes are suitable for both small- and large- capacity operations. The three basic steps in these processes are (a) kernel pre-treatment, (b) screw-pressing, and (c) oil clarification.

- What is palm kernel oil pressing process?

- Palm kernel oil pressing. Palm kernel oil pressing processing line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing.

- What is palm kernel cleaning & crushing?

- Palm kernel Cleaning : It is used for removing the iron impurities, stone, fiber and pthers. These impurities are bad for machines, especial for the palm kernel oil expeller. ◆ Palm kernel crushing: because the palm kernel is hard and big size, it is required to crash to smaller and even pieces.

- Why is palm kernel oil expeller bad?

- These impurities are bad for machines, especial for the palm kernel oil expeller. ◆ Palm kernel crushing: because the palm kernel is hard and big size, it is required to crash to smaller and even pieces. If once crashing can not reach the requirements, the second crashing is required.

- Which method is used in palm kernel separation?

- Wet separation is mostly used in palm kernel separation, on basis of difference of relative density of palm kernel and shell. ◆ Palm kernel drying. Fresh kernel contains 20% moisture. Palm kernel has no mildew during transportation and storage while moisture drops below 7%.

- How do you crush a palm kernel?

- Crush palm kernels after softening and drying. The centrifugal crusher breaks nuts and separate palm kernel out completely. ◆ Palm kernel and nuts shell separation.