Palm Oil Extraction Process, Methods, Steps Agri Farming

- Usage: Palm Oil

- Type: Palm Oil

- Production Capacity: 300-4000kg/h

- Voltage: 220v

- Dimension(L*W*H): 1247 * 382 * 1171mm

- Weight: 254 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, PLC, Gear, Other

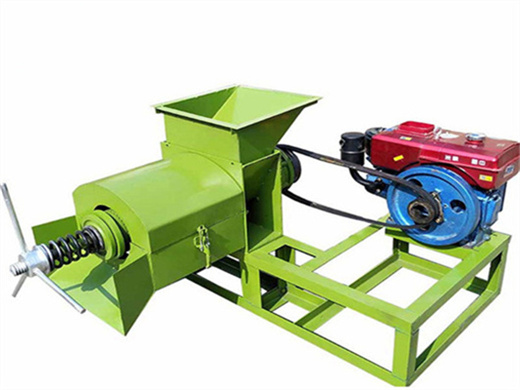

- Product name: Screw Oil Press Machine

- After-sales Service Provided: Video Technical Support

- Function: Making Palm Oil

- Application: Small Palm Oil Processing

- Advantage: Low Consumption High Efficiency

- Feature: High Oil Yield Efficiency

Palm oil extraction process: Palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. Palm oil extracting plant generally begins with the harvesting of the fruit. This is the process of palm oil physical extracting (screw pressing) and field factors that determine.

Palm oil is an oil with a high oil content, about 46-50%, and can be easily squeezed to produce oil. Better quality palm oil can be obtained through refining and fractionation. The first process of palm oil extraction begins at the palm oil extract plant, where fresh palm fruit bunches are received and processed.

Palm Oil Processing Machine Palm Oil Press Machine On Sale

- Usage: Palm oil extracting machine

- Type: Palm oil extracting machine

- Production Capacity: 1-2000TPD

- Voltage: 220V/380V/440V

- Power(W): 7.5kw

- Dimension(L*W*H): 2000x1400x1850mm

- Weight: 1200kg

- Application: Palm oil extracting machine

- Raw material: Palm

- Material: Stainless Steel 304

- Function: Palm oil extracting machine

- Character: Palm oil extracting machine

- Warranty: 2 Years

- Feature: Feeding Automatically

- Quality: Top Level

- Wearing parts: Squeeze Spiral

The extraction of palm oil from boiled palm fruit can be accomplished by handling successive batches of materials or continuously feeding material to the machines. 3.2.1 Batch systems. The batch systems work directly on successive loads of boiled fruit to extract oil in one operation for clarification.

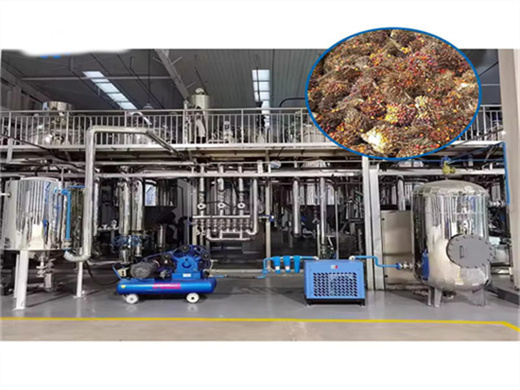

Time for palm oil extraction machines. PALM OIL EXTRACTION. Now we come to the central step in the palm oil production process: extraction. Separated palm fruits are processed to extract crude palm oil. Fibres and the palm kernel get left behind. There are two commonly used methods for palm oil extraction. Approach 1: wet method.

PALM OIL PROCESSING Palm Oil Mill Machine Leading

- Usage: Palm oil refinery plants

- Production Capacity: 80kg/h, 500kg/h, 100kg/h

- Voltage: 220V/380V/440V

- Power(W): 22kw

- Dimension(L*W*H): 48m*12M*15M(30TPD)

- Weight: 30tons

- Product name: Palm oil refinery plants

- Advantage: 40 years experience

- Application: Oil Production Line

- Production period: 45 days

- Installation period: 60 days

- Supplier Type: manufacturer

- Technology support: lifetime

Extraction of oil from the palm kernels is generally separate from palm oil extraction, and will often be carried out in mills that process other oilseeds (such as groundnuts, rapeseed, cottonseed, shea nuts or Palm). The stages in this process comprise grinding the kernels into small particles, heating (cooking), and extracting the oil using.

Palm oil refining process of palm oil production process: 1. Degumming: The clarified palm oil then needs to go through a refining process, the first step of which is degumming. Impurities such as phospholipids in crude palm oil are removed by physical dry degumming or chemically by adding 85% or 75% food grade phosphoric acid. 2. Deacidificating:

Palm Oil Extraction Process Palm Oil Mill Machine Leading

- Usage: Palm Oil

- Type: Palm Oil Expeller

- Production Capacity: 100%, 5T-200T per hour

- Voltage: 380V/50HZ, 380V /440V or the local voltage

- Power(W): 15KW, According to the capacity

- Dimension(L*W*H): 1700*1100*1600mm, According to the capacity

- Weight: 1200kg, According to the capacity

- Supplier type: Factory(more than 35 years experience)

- Capacity: 5T-200T per hour

At the same time, during the crushing process, the palm fruit (i.e., palm kernel) is separated, and then crushed and removed from the shell. The remaining kernels are extracted to obtain the crude palm kernel oil (CPKO) and palm kernel meal (PKE).The oil palm fruit contains two different fats and oils, and palm oil is obtained from the pulp.

Local and Modern Methods of Crude Palm Oil Extraction

- Usage: Palm Oil

- Type: Palm Oil production plant, Palm Oil production plant

- Production Capacity: 45~70kg/h

- Voltage: 380V

- Power(W): 2 KW

- Dimension(L*W*H): 1050*950*1650(mm)

- Weight: 1350 kg

- Suitable objects: Palm , Palm etc.

- Plant: 10㎡

- After sale service: Yes

- Business type: manufacturer

- Year Established: 1999

- Guarantee: 1 Year

- Accepted Delivery Terms: FOB, CFR, CIF, EXW

- Packing: Wooden package

The secondary crude palm oil extract is obtained by further processing palm oil milling residues, such as palm oil mill effluent (POME), fiber, and pressed chaff. It involves recovering residual oil trapped in these by-products, typically through mechanical pressing, decantation, or solvent extraction.

- How is palm oil extracted?

- Palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. Palm oil extracting plant generally begins with the harvesting of the fruit. This is the process of palm oil physical extracting (screw pressing) and field factors that determine quality of expelled palm oil.

- How to extract Palm oil from fruit?

- This is the process of palm oil physical extracting (screw pressing) and field factors that determine quality of expelled palm oil. For extracting oil from palm fruits, you will have to start by harvesting fresh fruit bunches and keeping them ready for the next stage of palm oil production.

- How do you extract oil from a palm tree?

- Extracting oil from the oil palm tree is a multi-stage process. It begins with the cultivation and harvest of the fruit from mature trees anywhere between the ages of four and 30 years. After the preparation of the fruit, it is transferred to a palm oil extraction machine.

- What is palm kernel extraction?

- Palm kernel extraction is a specialised operation undertaken by a completely different set of processors. They are usually better organized as a group and are not as dispersed as palm oil processors. The kernel processors have to go around the palm oil processors during the peak season, when prices are lowest, to purchase the nuts for drying.

- What are the steps in palm oil production?

- PALM FRUIT PREPARATION Step 1: inspection. When they arrive at a palm oil processing unit, the palm fruits are first inspected and subjected to quality assessments to ensure that only good quality fruit makes it to the palm oil production line. Step 2: sterilization.

- How does palm oil production process work?

- Step 1: inspection. When they arrive at a palm oil processing unit, the palm fruits are first inspected and subjected to quality assessments to ensure that only good quality fruit makes it to the palm oil production line. Step 2: sterilization. Then, the FFBs are sterilized, with high-pressure steam destroying bacteria and deactivating enzymes.