Palm Oil Processing Machine Palm Oil Press Machine On Sale

- Usage: Palm OIL

- Type: Automatic Palm Fruit Oil Processing Machine

- Production Capacity: Rose Essential Oil Extractor

- Voltage: 220V

- Dimension(L*W*H): 67*35*50cm

- Weight: 12.5 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Gear

- Item: Household Essential Oil Distilling Machine

- Function: Make Essential Oil

- Application: Distillation Flowers Herb Roots Plants

- Tank volume: 10L

- Operation: one person

1 General processing description. Research and development work in many disciplines biochemistry, chemical and mechanical engineering and the establishment of plantations, which provided the opportunity for large-scale fully mechanised processing, resulted in the evolution of a sequence of processing steps designed to extract, from a harvested oil palm bunch, a.

Palm oil extraction process: Palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. Palm oil extracting plant generally begins with the harvesting of the fruit. This is the process of palm oil physical extracting (screw pressing) and field factors that determine.

BRITISH COLONIAL POLICIES AND THE OIL PALM INDUS- TRY IN THE

- Usage: Palm Oil, Cooking Oil

- Production Capacity: More than 95%

- Voltage: 220V/110V

- Dimension(L*W*H): 650*670*1125 mm

- Weight: 85 KG

- Core Components: Motor, PLC, Gearbox

- Oil type: Palm Oil

- Product name: oil press machine

- Apply to: oil mill, home use, oil factory

- Production: 20-30 kg/h

- Control method: automatic with oil filter

- Advantage: with vibration amplitude controller

- Press type: Hot&cold pressing

- Machine material: stainless steel screw and chamber

- Package: Export plywood package

- Features: oil press with oil filter

Since the oil palm industry was a principal source of revenue for the people, it had its pantheon deity called Edjokpa. This goddess protected the people as they executed their duties relating to oil extraction. In return, the deity was venerated before the palm bush could be declared of?cially open for tapping. In some parts of

This stage involves careful quality control and adherence to strict regulations to ensure that the palm oil meets the required standards for use in various applications. Palm Oil Powerhouse: QIYI Machinery's Superior Palm Oil Milling Solutions . QIYI Machinery is a leading manufacturer specializing in palm oil milling equipment.

OLEOCHEMISTRY Chapter 3- Palm Oil Processing UMP

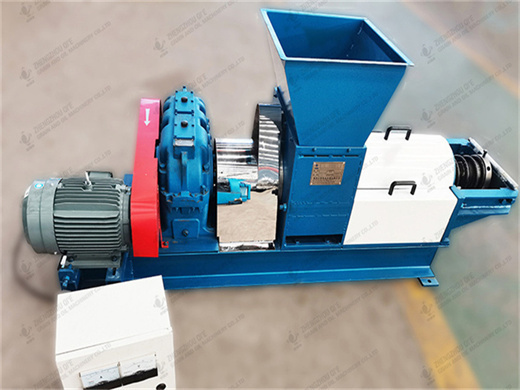

- Usage: Palm Oil Extruder Machine

- Type: Oil Pressing Machine

- Production Capacity: 98%-100%

- Voltage: 380

- Power(W): 5.5KW~15KW

- Dimension(L*W*H): 2200*1600*2150

- Weight: 780kg

- Capacity of cold pressed Palm oil: 35kg-400kg/h

- Material of cold pressed Palm oil: Stainless Steel SS304/316

- Residual oil rate: 5~7%

- Raw material: Palm

- Warranty period: 12 months

- Application range: Oil Production Line

- Feature of cold pressed Palm oil: High Oil Yield Efficiency

- Function of cold pressed Palm oil: Produce High

- Character: Palm Oil Extruder Machine

Palm oil processing. WHY REFINING 1. Remove unwanted compounds from fats & oils after extraction before human consumption or for industrial use. 2..

In direct screw pressing, kernels must undergo seed preparation steps of size reduction, flaking and steam conditioning prior to mechanical extraction. Mechanical wear and tear, maintenance expenses and electricity are the major costs.The direct solvent extraction process is used in larger plants. Production cost depends mainly on solvent loss and energy used in solvent recovery and.

5. PALM KERNEL OIL EXTRACTION Food and Agriculture Organization

- Usage: Palm Oil, Cooking Oil

- Type: Oil Extraction Machine, Cold Pressing Machine

- Production Capacity: 1.3TPD

- Voltage: 360v

- Dimension(L*W*H): 1094*405*806 mm

- Weight: 195 KG

- Warranty: 6 Months

- Core Components: Other, Gear, Gearbox, frame, Squeezing part, Feeding system

- Oil type: Palm Oil

- Item: Small Oil Press machine

- Feature: Small Model for commercial store or small capacity business

- Used for: soja Palm Oil Making

- Advantage: High Efficient and small investment

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

Methods of Palm Oil Processing in Ogun state, Nigeria: A

- Usage: Palm

- Type: screw pressing

- Production Capacity: 45%-55%

- Voltage: 220V

- Dimension(L*W*H): 1350*1170*2000

- Weight: 270 KG

- Core Components: Motor

- Oil type: Palm Oil

- Palm oil press machine pressure per kg: 1600KN 2200KN 3000KN

- oil press machine heater ring power: 7.5kw

- Max working pressure: 55Mpa

- heater ring controll temperature: 70-100C

- per time mateiral adding weight: 250kg

- Raw material: Oil s

- Function: Press Oil s

- Feature: High Oil Yield Efficiency

The oil palm is one of the important economic crops in the tropics (Anyawu et al., 1982). It is the most important source of oil and produces more oil per hectare than any of the oil producing crops. The primary products of the oil palm are palm oil (from the mesocarp) and palm kernel oil obtained from the kernels (seeds). Palm oil contains

- How palm oil is extracted?

- In the dry method, the fruit is first cooked by dry heat followed by extraction procedures. These two methods produce different grades of oil. The standard procedure of oil extraction is through the use of organic solvents. Recently, impact of organic solvents on environment. The extracted oil Figure 1. World palm oil production in 2011.

- How to extract Palm oil from boiled palm fruit?

- The extraction of palm oil from boiled palm fruit can be accomplished by handling successive batches of materials or continuously feeding material to the machines. The batch systems work directly on successive loads of boiled fruit to extract oil in one operation for clarification.

- When was palm oil discovered?

- The finding of oil that may have been palm oil in an Egyptian tomb dating back to 5000 BP. The presence of oil palm pollen in early deposits in the Congo dating from 24000 BP and in the Cameroons from 2730 BP. The discovery of fossil seeds and shells of oil palm in Uganda, the latter dating from 5000 BP.

- How much palm oil can be extracted from tenera?

- Most processing operations are automatically controlled and routine sampling and analysis by process control laboratories ensure smooth, efficient operation. Although such large installations are capital intensive, extraction rates of 23 - 24 percent palm oil per bunch can be achieved from good quality Tenera.

- Why is oil palm cultivation a problem in West Africa?

- The successful establishment and expansion of oil palm cultivation has been much dependent on the availability of suitable facilities for extracting oil and kernels from harvested fruit bunches. This was one of the factors that initially impeded development of the industry on a plantation scale in West Africa (Hartley, 1977).

- How did the price of palm oil change from 1950 to 1990?

- From 1950 to the 1990s, there was a clear, downward trend in the infla tion‐adjusted price for palm oil (Fry, 1998). In the sec ond half of the twentieth century, inflation‐adjusted market prices for all agricultural commodities declined at 1.5–3.5% per year. Palm oil declined at 3% (Fig. 1.4), soya bean oil at 3.1% and coconut oil at 2.9%.