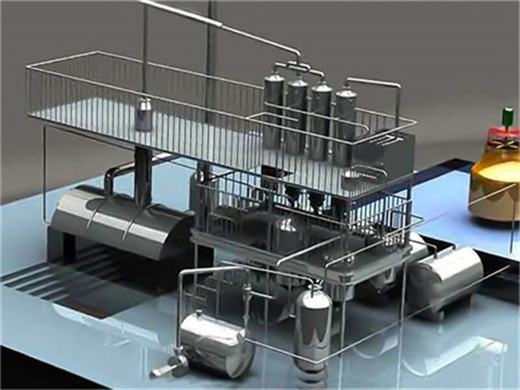

Small Scale Oil Refinery Plant

- Usage: biodiesel refinery

- Type: interesterification way

- Production Capacity: 100%

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): according to capacity

- Weight: various

- After-sales Service Provided: Overseas service center available

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Product: high quality biodiesel can be used as diesel

- Capacity: 5-600T

- Function: biodiesel refinery

- Manufacturing experience: 20 years experience

- Material of equipment: stainless steel and carbon steel

- Oil yield rate: 85%

- Market: more and more countries ask biodiesel

QIYI Machinery sets of small scale cooking oil unit equipment won the national patent (patent number: ZL 99 252888.7), is currently developing the third generation of our edible oil making machine.Our small scale oil refinery plant are great choice for small capacity oil refinery machine.The small scale oil refinery production plant can

It is to extract the oil from the oil material by pressing. four types of oil pressing are usually used. 1, Single pressing is usually applied at small-capacity oil milling plants. 2, Pre-pressing is for larger capacities oil mill plants. 3, Hot Pressing is to cook the oil seeds before pressing to get a high oil press yield. 4, Cold Pressing is to press oil seeds using only the application of

Types Of Cooking Oil Refining Machine Edible Oil Refinery Plant

- Usage: Cooking Cooking oil refining machine

- Type: Cooking Cooking oil refining machine

- Production Capacity: 50-200TPD

- Voltage: 380V or 440V

- Power(W): according to the capacity

- Dimension(L*W*H): according to the capacity

- Weight: according to the capacity

- Color: Yellow

- description: Continuous automatic oil refining machine

- steam consumption: 450kg/T oil

- phosphoric acid:

- electric consumption: 28kwh/T oil

- Bleaching earth consumption: 5~50Kg/Toil

- Waste bleaching earth oil content: <35%

- Deodorization loss consumption: ≤0.5%

It is available for refining palm oil, palm kernel oil, corn germ oil, peanut oil, soybean oil, sunflower seed oil, rapeseed oil, rice bran oil, coconut oil, etc. Contact Us. Please kindly leave your requirements in detail or contact us via +86 13526627860. Our professional project manager will contact you within 24 hours.

Parameter Capacity of Oil Refinery; 3- Tons Per Day: 5- Tons Per Day: 10- Tons Per Day: Machinery Costing: Approx $50,000: Approx $75,000: Approx $1,30,000: Covered Building Area (in meters)

Edible Oil Refinery Machinery

- Usage: Cooking Oil

- Type: Oil refining machine

- Production Capacity: 100TPD

- Voltage: 230-380-430

- Power(W): 40kw/h

- Dimension(L*W*H): 50m*30m*15m

- Weight: 50tons

- After-sales Service Provided: Overseas third-party support available

- Machinery type: Refinery plant for Cooking oil

- Capacity: 30-1000tons

- Oil loss: less than 5%

- Refining type: semi continuous and full continuous

- Vacuum degree: high vacuum

- Function: crude oil refining

- Steam consumption: less than 300kg/t oil

- Working mode: circulation usage of steam

- Soft water consumption: about 160kg/h

- Color: light yellow

China Edible Oil Refinery Machinery wholesale Select 2025 high quality Edible Oil Refinery Machinery products in best price from certified Chinese Oil Machine manufacturers, Oil Machinery suppliers, wholesalers and factory on Made-in-China.com

Small scale oil refining plant Introduction: QIYI Machinery sets of small scale cooking oil unit equipment won the national patent (patent number: ZL 99 252888.7), is currently developing the third generation of our edible oil making machine.Our small scale oil refinery plant are great choice for small capacity oil refinery machine.The small scale oil refinery production plant can remove

Equipment For Small Scale Edible Oil Processing Machine

- Usage: Cooking Oil

- Type: cooking oil refinery plant

- Production Capacity: 2T/D---10T/D

- Voltage: 380v/50Hz

- Power(W): up to specification

- Dimension(L*W*H): up to specification

- Weight: up to specification

- Function: cooking oil refinery plant

- Capacity Model: 5~2000T/D

- Suitable material: crude oil

- Patent product: Yes

- Patent No.: ISO9001

- Fully automatic: Yes

- Technology support: life time

- Warrenty: one year

- After-sale service: Offering installation and debugging

The small scale edible oil refinery plant usually use batch type edible oil refinery plant, including degumming and deacidification tanks and decolorization tank and deodorization tank. In this article, we will discuss the common equipment used in small scale edible oil refinery plant. Small scale edible oil refinery plant. Degumming tank:

Edible Oil Filter Machine For Purify Crude Oil, Oil Filter Press

- Usage: crude Cooking oil refinery machine

- Type: Cooking Oil Refinery Machine

- Production Capacity: 100TPD caster oil plant

- Voltage: 220V/380V/440V

- Power(W): depend on capacity

- Dimension(L*W*H): depend on capacity

- Weight: depend on capacity

- After-sales Service Provided: Overseas service center available

- Keywords: crude Cooking oil refinery machine

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: oil extraction machine

- oil rate: 20%-98%

Refinery Equipment. Small Edible Oil Refinery Plant; Crude Oil Degumming System; Crude Oil Deacidification System; Crude Oil Decolorizing Equipment; Crude Oil Deodorizing Tower; Oil Dewaxing,Fractionation; Batch Type Small Edible Oil Refining Plant; Cotton Seed Oil Refinery Plant; Plate Pressure Oil Filter; Edible Oil Filling Packing Machine

- Who makes edible oil refining equipment & services?

- With a focus on quality and advanced technology, they provide comprehensive equipment and services for refining edible oils. The N&T management team is composed of experts with more than 40 years of expertise in the manufacturing of edible oil refinery machinery and equipment.

- Why should you choose N&T for your edible oil refinery?

- N&T is dedicated to providing high-quality edible oil refinery machines that require little to no maintenance with a wealth of manufacturing and processing expertise. Our edible oil refinery package is efficiently designed to maximise production in available working areas. Thus allow us to design compact equipment that uses low space.

- How to refine edible oil?

- The procedure we use to refine edible oil is as follows: Oil contains both hydratable and non-hydratable gums. Hydratable gums are removed by water degumming. N&T had developed the process for proper gum conditioning and caustic neutralisation, this process reduces the phosphorus content to the desired limits.