Palm Oil Dry Fractionation, Solvent Fractionation, Surfactant

- Usage: All kinds of edible oil

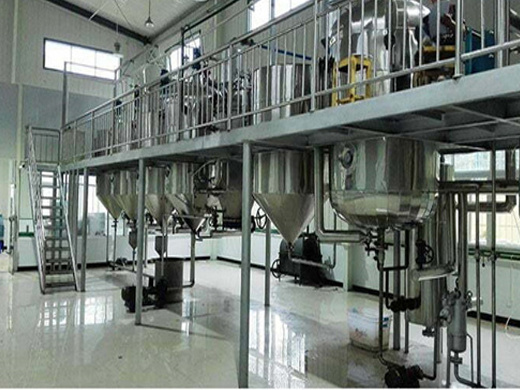

- Type: Cooking Oil Refinery Machine

- Production Capacity: 100%

- Voltage: 380V OR REQUESTED

- Power(W): 300KW

- Dimension(L*W*H): 14X8X9M WORKSHOP

- Weight: 10T

- material: stainless steel or others

- Capacity: accordding to your requirement

- outstanding: low price, fast return

- Distillation range: 68-75℃

- Installation time: 30-45 days

- Delivery Time: 30 days

- Delivery port: Qingdao port

- Project: Turn key project

- Item: oil refining equipment

A Kenyan client successfully ordered an integrated edible oil pressing machine and 2tpd edible oil refinery machine from Henan Glory Company; What is a comprehensive guide to setting up the best cpo refinery plant? The 0.5TPD edible oil refinery machine have been successfully shipped from Henan Doing company to Uganda

India has around 550 units of edible oil refineries located in different States. The sources of edible oil manufacture are soyabean, groundnut, rapeseed, sunflower, safflower, cotton, sesame, coconut, palm, mustard, rice bran, watermelon, neem, mahua etc. The refined edible oil manufacturing units generate solid waste (spent earth) and wastewater

Edible Oil Refining Process Flow Chart Introduction_Tech

- Usage: crude Cooking seed oil refinery equipment

- Type: crude Cooking seed oil refinery equipment

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 10-50kw

- Dimension(L*W*H): 46*32*12m

- Weight: 30tons

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Application: crude oil refinery

- Product name: crude Cooking seed oil refinery equipment

- Handling capacity: 5tpd-300tpd

- Power consumption: 18.8kw/h

- Steam consumption: 300kg/t

- Refinery rate: 96%

- Refinery method: Physical and Checmical

- Advantage: Energy Saving

- Warranty: 12 Months

Edible oil refining process flow chart is usually designed by engineers according to customer's plant area and process requirements. Generally, edible oil refining process flow chart has three types based on the input capacity, batch type edible oil refining process flow chart, semi- continuous edible oil refining process flow chart and full

This continuous palm oil physical refining process flow chart is based on our engineers' designing palm oil physical refining technology, which is for 100tpd continuous palm oil refinery plant project in Kenya. It is different from other oil refining process, such as soybean oil refining process, sunflower oil refining process, etc.

The Importance Of Steam Deodorization In Edible Oil Refining Machine

- Usage: Cooking Oil refining equipment

- Type: Cooking oil refining equipment

- Production Capacity: 5T~10T/D

- Voltage: 220V/380V

- Power(W): according to capacity

- Dimension(L*W*H): depend on capacity

- Weight: according to capacity

- Item: Cooking oil refining equipment

- Application: various crude oil like Cooking oil

- Operating ways: safe and simple

- Residual oil in cake: low

- Oil grade: high

- Cultivation Type: organic

- Processing Type: refined

- Refining technics: batch refining, semi-continuous refining

- Moisture and volatile: 0.08%

See the following edible oil refining process flow chart they send to customers. Other manufacturer’s edible oil refining process flow chart. As you can see, this edible oil refining process flow chart doesn’t contain deodorization part, and the deacidification part and the time of separation and standing are not standard refining process.

Sunflower Oil Refining Process Flow Chart. Sunflower Oil Refining becomes successful with the help of series of treatment processing being made through equipments in controlled conditions. Every refinery equipment leads to betterment in the oil quality.

Ivory Coast Lets Technology Contract For Abidjan Refinery

- Usage: Multi-functional

- Type: Oil refining plant

- Production Capacity: 160kg/h

- Voltage: 220V/380V

- Power(W): 4.3KW

- Dimension(L*W*H): 3750*850*1990MM

- Weight: 310

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Application: Oil Production Line

- Material: Stainless Steel SS304/316

- Function: Oil refining

- Advantage: Simple Operation

- Warranty: 12 Months

- Color: Customers' Request

- Cycle time: 2.5h

- Working time: 24 hours

According to SIR’s website, the Abidjan refinery includes two 75,000-b/d atmospheric distillation units, and 18,000-b/d hydrocracker, as well as the following major installations: A vacuum

Edible Oil Refining Process Flow Chart Introduction

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Automatic Grade: Semi-Automatic

- Production Capacity: 100%

- Voltage: 220V/380V

- Power(W): 7.5kw

- Dimension(L*W*H): Based on Oil Press Machine capacity

- Weight: 1200kg

- Product name: Cooking oil refinery factory building

- Advantage: Energy Saving

- Warranty period: 12 months

- Application range: Oil -bearing Material

- Function: Refining Vegetable Oil

- Item: Vegetable Oil Refining Machines

- Use for: Vege

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Section: Oil Refinery Machine Section

- Product: National Oil Standard

Edible oil refining process flow chart is usually designed by engineers according to customer's plant area and process requirements. Generally, edible oil refining process flow chart has three types based on the input capacity, batch type edible oil refining process flow chart, semi- continuous edible oil refining process flow chart and full

- What is the process of refining crude vegetable oil into edible oils?

- The document discusses the process of refining crude vegetable oils into edible oils. It describes the major steps in oil refining which are degumming, bleaching, and deacidification to remove impurities and free fatty acids.

- What equipment is used in an edible oil refinery?

- The key equipment used in an edible oil refinery are neutralizers, bleachers, deodorizers, filters, tanks, and associated pumps. The refining process heats and treats the oil to remove color, odor, and other undesirable components through various chemical and physical processes to produce a refined edible oil suitable for human consumption.

- What are the major steps in oil refining?

- It describes the major steps in oil refining which are degumming, bleaching, and deacidification to remove impurities and free fatty acids. The key equipment used in an edible oil refinery are neutralizers, bleachers, deodorizers, filters, tanks, and associated pumps.

- How do you refine edible oil?

- For refining the edible oil, there are three basic processes in the refinery. (FFA) by adding caustic soda. • Oil is heated up to about 60°C by thermic fluid coils and oil is stirred by stirrer. the neutralizer from where it is taken out into soap pan. bleaching earth. Oil is generally heated up to 110°C by thermic fluid coils.

- What is palm oil refining process?

- An overall summary of the palm oil refining process is an example of vegetable oil processing and depicted in Figure 1 It is important to remove impurities from the refined vegetable to ensure that the quality requirements are met and the oils are safe for consumption. The quality of the extracted oils Figure 1. ...

- Can crude oil be consumed directly?

- Usually, apart from virgin oils, crude oils cannot be consumed directly or incorporated into various food applications without technological treatments (refining). Indeed, crude oils like soybean, rapeseed, palm, corn, and sunflower oils must be purified or refined before consumption.