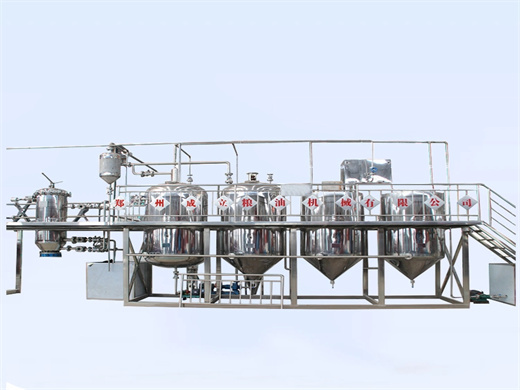

Vegetable Oil Refinery Plant (Physical &Amp; Chemical)

- Usage: Cooking Oil Refinery Plant

- Type: Cooking Oil Refinery Machine, Cooking Oil Refinery Plant

- Production Capacity: 5-300TPD Cooking Oil Refinery Plant

- Voltage: 380V

- Refining process: Degumming,Deacidification,Decolorization,etc

- Oil quality: 1st,2nd,3rd,4th,salad oil,cooking oil

This process separates different triglycerides in the oil based on their melting points, allowing for the production of specific fractions with desired properties.Vegetable oil refinery plants, Physical refining of vegetable oils, Chemical refining technology, Edible oil processing plants, Advanced refinery solutions, Customizable refinery systems, Turnkey refinery plant solutions

Ambika Oil Industries Manufacturer of best quality Palmolein Oil in Hyderabad, Telanagana, India; Geeta Refinery Pvt. Ltd. Edible Oil Refinery Plant and Solvent Extraction in Jalna, Maharashtra,… Surana Cotton Industries Address Gut No. 673, Opp. Gajanan Nagari, Meti Kheda… SHRIRAM OIL INDUSTRIES Manufacturer Of Cotton Seed Oil Cake in

Soybean Oil Refinery Plants Manufacturer In India,Technology

- Usage: seed oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 1-1000TPD

- Voltage: 220V/380V

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Advantage: Simple Operation; Saving Energy; High oil yield

- Material: Stainless Steel and Carbon Steel

We are leading manufacturer and exporter of Soybean Oil Refinery Plant for processing the crude soya oil into the refined soya oil -SHFT Nagpur Office Time : Thursday To Tuesday 9:30 am 7:00pm

Get Neutralizer Refinery, For Cotton Seed Oil, Capacity: 5-20 ton/day at best price in Ghaziabad, Uttar Pradesh by Azad Engineering Company and more manufacturers ID: 2358580655

Edible Crude Oil Refinery Machine Machinery Equipment Plant

- Usage: Cooking Oil making machine

- Type: Cooking oil making machine

- Production Capacity: 10-1000MT

- Voltage: 380V

- Power(W): According to capacity

- Dimension(L*W*H): According to capacity

- Weight: According to capacity

- Item: Cooking oil making machine

- Supplier type: Manufacturer

- Manufacturing experience: 19 years

- Steel type: MiId steel and SS

- Raw materials: Cooking/ Cooking

- Fina product: High quality cooking oil

- Processing method: Machanical press

- Handling capacity: 10-1000MT

- Model type: Continuous

About Pemac Projects Pvt. Ltd., Manufacturer, Supplier, Service Provider of Edible Oil Refinery Plant, Air Cascade Cotton Seed Cleaner, Cotton Seed Dehulling Machine from Navi Mumbai, Maharashtra.

Welcome to Shri Hari Fabtech India Pvt. Ltd,a premier provider of advanced Palm Kernel Oil Refinery Plant designed to ensure superior quality and efficiency. We specialize in designing and manufacturing state-of-the-art facilities that refine Palm Kernel Oil to meet global standards and exceed client expectations.

Oil Refinery Plant Biodiesel Refinery Plant Latest Price ..

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine, Cooking Oil Refinery Machine

- Production Capacity: 300TPD Cooking Oil Refinery Machine

- Voltage: 380V

- Material: Stainless and Carbonless Steel

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Cooking Oil Machinery Process: Pre-treatment,Solvent Extraction,Refining

- Pretreatment Process: Cleaning,Hulling,Breaking,Soften,Flaking,Puffing,Toasting

- Solvent Extraction Process: DTDC,Miscella Toasting and Stripping,Solvent Collecting,etc

- Process Capacity: 300TPD

- Refining Process: Degumming,Deacidification,Deordorization,Decoloration,etc

- Service: Engineer Abroad Erection

- Packing: Frame and Container

Cooking oil refinery plant; Edible oil deodorization plant; Waste oil to diesel plant, capacity: 10 ton/day; Automatic oil refinery plant; Physical refining plant; Ss,ms rice bran oil refineries, >20, capacity: 20-1000 tpd; Continuous deodorizing section; Industrial oil refining, capacity: 1000 ton/day; Oil refinery plant; Commercial expeller

List Of Oil Refineries In India

- Usage: Oil Refinery Machine

- Type: Cooking Oil Refinery Machine

- Production Capacity: As Oil Refinery Machine capacity

- Voltage: As Oil Refinery Machine capacity, 220V or 380V

- Power(W): As Oil Refinery Machine capacity, Accoding to your capacity

- Dimension(L*W*H): As Oil Refinery Machine capacity

- Weight: As Oil Refinery Machine capacity

- Item: rubber oil refining equipment

- Color: As Oil Refinery Machine capacity capacity

- Processing: Oil press, extraction, refinery

- Phosphoric acid: 2~3 kg/T oil

- Refining rate: Refining consumption 1%

- Supplier type: Manufacturer

- Waste bleaching earth oil content: 25% to 35 %

- Soften water: 150Kg/T oi

After discovery of oil in the Assam state of India in late 1880s, the first oil refinery was set up at Digboi. Digboi Refinery was commissioned in 1901. [1] Following is a list of oil refineries in India, per the Petroleum Planning and Analysis Cell of the Ministry of Petroleum and Natural Gas, Government of India, [2] arranged in decreasing order of their capacity.

- What is cottonseed mixed oil refining?

- Cottonseed Oil Refining Plant Cottonseed mixed oil refining is to degum and deacidify the mixed oil (the mixture of solvent and oil) gained from the first vaporization system in cotton seed extraction technology before it is not totally evaporated and desolventized, and before its viscosity and density are lower than crude oil.

- What is the history of cottonseed oil industry in India?

- In India traditionally, the cottonseed utilisation has been as an animal feed and it was in 1914 that Indian Oil Company established the first cottonseed oil mill at Navsari. Since then the Indian cottonseed oil industry has come a long way. 1. Cotton Production (Lakh bales) 2. Cottonseed Production (@333Kg/bale) (Lakh tonnes) 3.

- What is cotton seed oil?

- We are a global reputed manufacturer and exporter of Cottonseed Oil Refinery Plant with our manufacturing facilities in Ludhiana ( Punjab ), India. The Cotton Seed Oil is the Oil extracted from cotton seeds which are obtained after removing cotton fiber, lint and hulls. The Kernel in the cotton seed contain oil.

- How a cottonseed oil plant can achieve 500 t/d?

- The combination use of the cottonseed extrusion, oil extraction and the mixed oil refining process can make the production of our cottonseed oil plant reach 500 t/d. The extrusion & extraction technology can improve the oil yield and reduce the solvent loss.

- How is cotton seed oil produced?

- The production of cottonseed oil has 3 methods: mechanical screw oil pressing, pre-pressing & solvent extraction, and direct solvent extraction. Cotton seed oil pressing mainly rose in 1960s when cottonseed oil was pressed by small batch type cold oil press machine and sold in the form of crude oil.

- What is cottonseed oil obtained from solvent extraction?

- Cottonseed oil obtained from solvent extraction is crude oil. Figure 11, gives an idea about various steps involved in extracting cottonseed oil through scientific method. The crude oil contains varying levels of non-triglyceride materials, the majority of which would be considered impurities in most finished oils.