Processing Technology Of Rice Bran Oil Sciencedirect

- Usage: crude Cooking oil refinery manufacturers

- Type: crude Cooking oil refinery manufacturers

- Production Capacity: 100%crude Cooking oil refinery manufacturers

- Voltage: 220V/380V/440V

- Power(W): 10-50kw

- Dimension(L*W*H): According to processing capacity

- Weight: According to processing capacity

- Item: Crude Cooking oil refinery manufacturers

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Steam pressure: ≥1.2MPa

- Voltatile substance in crude oil: ≤0.3%

- Steam consumption in refining: ≤280kg/ton of oil

- Oil residue in waste clay: ≤25% of waste clay

- Solvent contain in crude oil: ≤200ppm

- Oil residue in meal: <1%

- Warranty: 2years

- Feature: High Oil Yield Efficiency

This process (Cavanagh, 1974) separated > 90% of rice bran Waxes miscella phase dewaxing is a well-known process in Japan as the solvent plants are quite large. In addition, miscella dewaxing also depends on the oil content in the miscella, operating temperature, and inclusion of additives (calcium chloride, etc.).

We are the leading players in managing end-to-end operations for leadin national and multi-national companies in India. Our customers can finally focus on their core areas, while fully entrusting us to manufacture, pack and ship the various SKU’s as per their requirements and quality standards.

Process Of Rice Bran Oil Production Line

- Usage: cooking Oil Refining

- Type: Oil refinery

- Automatic Grade: Automatic, Automatic

- Production Capacity: 200---300T/D

- Voltage: adjusted to the refining equipment

- Refining Grade: RBD Oil

- Refining Main Machine: Deodoriser,Clay Tank,etc

- Refining Process: Degumming,Deordorization,Decolorization,etc

- Steel: All equipment in Type 304 steel

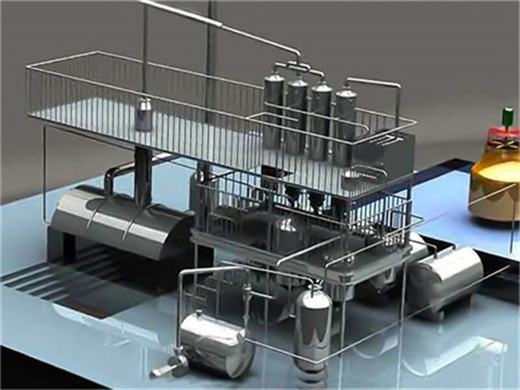

The process of rice bran oil production involves three main steps: pretreatment, extraction, and refining. Hua County Henan Province, China +8615937289608 [email protected] Follow on us :

Degumming. Rice Bran oil contain phosphatides like other oils 1.5% max. This will be removed through the standard degumming process by addition 2% water and 1kg to 1.5Kg of food grade phosphoric acid to the oil at 60°C and allowing to mix for 20 minutes and then by separating through the centrifugal separators.

Rice Bran Oil Production Process

- Usage: hot sell Cooking seed oil refining machine price for sale

- Type: Cooking Oil Refinery Machine

- Production Capacity: 45 sets per year

- Voltage: 380V/440V

- Power(W): 30KW

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 500TON

- Usage: hot sell Cooking seed oil refining machine price for sale

- oil clolor: yellow

- advantage: save energy

- bleaching earth consumption: 5-50kg/t oil

- decolor function: remove the bad color

- deodor function: remove the bad smell

Completed rice bran oil processing plant includes rice bran oil pretreatment or extrusion, rice bran oil extraction and rice bran oil refinery. Hua County Henan Province, China +8615937289608 [email protected]

As the screw worm moves, the space becomes smaller and smaller, thus squeezing rice bran oil out. Then the fresh rice bran oil seeps out through the small openings in the bottom of the squeezing barrel where the rice bran oil cake cannot pass through, and thus separating rice bran oil from oil cake. After collecting rice bran oil cake, rice

Cost Of Setting Up A Rice Bran Oil Refinery Plant ..

- Type: flexseed oil refining

- Use: flexseed oil refining

- Production type: flexseed oil refining

- Machine application: flexseed oil refining

- Workers needed: 2-3person

- Steam consumption: less than 300kg/t oil

- Soft water consumption: about 160kg/h

- Operation time: 24hours

- Dimension(L*W*H): 20m*16m*15m

- Voltage: 230V-380V-430V

- Machine material: carbon steel or stainless steel

But if you own process crude rice bran oil, then less it will cost to set up a rice bran oil refinery plant. 3.Rice bran oil refinery machine cost. There are mainly three kinds of rice bran oil refinery machine: batch type, semi-continuous type and full continuous type.

Rice Bran Solvent Extraction Plants Rice Bran Oil Solvent ..

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 98%

- Voltage: as Cooking oil refinery plant capacity

- Power(W): as Cooking oil refinery plant capacity

- Dimension(L*W*H): as Cooking oil refinery plant capacity

- Weight: As Cooking oil refinery plant capacity

- Item: Cooking oil refinery plant

- Method of Cooking oil process: extrusion and leaching, and refining

- Refining ratio: 97%

- Water consumption: about 4 ton

- Process of refining: degumming, bleaching, deodorization

- Temperature of deodorization: about 280 degree

- Standard of refined oil: grade two and one

- the by-products of bleaching: waste white clay

- Method of refinery: chemical and physical method

- Shipping method: by sea

Here's an overview of the process involved in such a plant : 1. Oil Refining: The crude rice bran oil obtained from the extraction process undergoes refining to