Cooking Oil Refining Machine South African

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 300TPD

- Voltage: 220V/380V/440V

- Power(W): According to the different capacity

- Dimension(L*W*H): According to the different capacity

- Weight: According to the different capacity

- After-sales Service Provided: Overseas service center available

- Warranty: 3 Years

- Application: Plant Seed,stem,foliage

- Processing Types: Seeds Oil Refining

- Color: as your request

- texture: SS or CS

cooking oil refining machine south african,prices for cooking oil refining machines in south africa,Hence, there will remain a serious interest in new developments that make chemical refining more attractive. Edible oil refinery can remove the phospholipid, FFA, pigment, peculiar smell and other impurities in the crude oil, it includes degumming, deacidification, bleaching, deodorization

Amidst all the above, TINYTECH has tried a bit to develop Tiny Technology machinery plants which are economical and viable. “Small Scale Oil Refinery Plant” is an innovative Oil Refining Unit for the Edible as well as Non-Edible Oils. Our research to invent the small scale refinery in early 20’s resulted into a great achievement.

Oil Refining Equipment,Oil Press Equipment,Dewaxing Equipment ..

- Usage: crude Cooking oil refining making machine

- Type: Cooking Oil Refinery Machine

- Production Capacity: 45 sets per year

- Voltage: 380V/440V

- Power(W): 30KW

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 500TON

- Usage: crude Cooking oil refining making machine

- oil clolor: yellow

- advantage: save energy

- bleaching earth consumption: 5-50kg/t oil

- decolor function: remove the bad color

- deodor function: remove the bad smell

1TPD. Crude Oil is mainly further processed into edible oil for food purpose. To meet the international industry’s standards for edible oil, the crude oil produced by oil mills should be refined in oil refinery plant.

>20TPD Oil Refinery Plant Project Coconut Oil Refining Process Expert Tips for smart investment High-Effect Rice Bran Oil Refining Process Low-Cost Solutions Proven Sunflower Oil Refining Process to Better Refined Results Soybean Oil Refinery Process and Machines Explained: Maximize Efficiency

Build Your Own Small Cooking Oil Refinery Plant For Making ..

- Usage: Cooking Oil

- Type: Cooking oil

- Production Capacity: 98%

- Voltage: 380V,as required

- Power(W): refer to capacity

- Dimension(L*W*H): refer to capacity

- Weight: refer to capacity

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Capacity: 1-1000TPD

- Main production line: Cooking prepressing plant, solvent extraction plant, oil refinery

Offer Customized Cooking Oil Refining Plant. After oil is extracted from vegetable seeds, the crude oil should go through a number of different processes in cooking oil refinery plant to make it ready for human consumption. Simply defined, refining is the process of removing impurities which may be present in the crude oil. Such impurities

20T/D fuel oil processing line in South Africa. 30T/D soya extruding and pressing plant in nigeria. 50T/D soya oil refining in Peru. 50T/D oil filling&bottle blowing machines line in Zambia. 50T/D cotton seed oil pressing plant in India. 50T/D soyabean pressing & refining complete oil mill plant in Brazil..

High Grade Cooking Oil Refinery Machine For Small &Amp; Large Plant

- Usage: crude Cooking oil refining process

- Type: Cooking Oil Refinery Machine

- Production Capacity: 50T~100T/D

- Voltage: 220V/380V

- Power(W): 28KWh/T

- Dimension(L*W*H): according to capacity

- Material: stainless steel and carton steel

- Steam consumption: <280KG/T (0.8MPa)

- Business type: manufacturer

- Crude oil moisture and volatile matter: <0.3%

- Item: crude Cooking oil refining process

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Dimension: depending on capacity

Small scale edible oil refinery machine. The small cooking oil refinery machine is suitable for small-scale oil mills or plants. It is specially designed for small oil refining and oil-refining complete sets of units, and realizes degumming (dehydration, dephosphorization), deacidification, decolorization, deodorization, thus achieving large

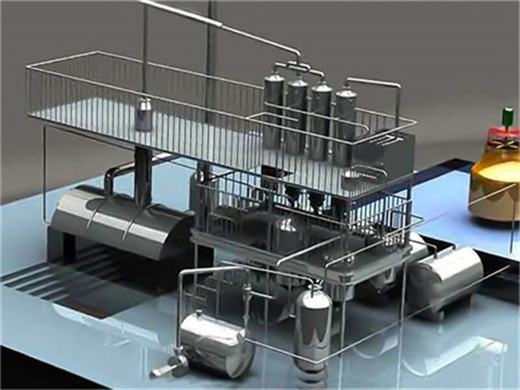

Equipment Layout Design Of Mini Oil Extraction &Amp; Refinery ..

- Usage: all vegetable seeds crude oil refinery machinery

- Type: automatic

- Production Capacity: 10-500TPD oil refinery machine

- Voltage: 380V or according to your request

- Power(W): according the capacity

- Dimension(L*W*H): according the capacity

- Weight: according the capacity

- color: silver or according to your request

- type: edible oil refinery machine

- Use:

- description: semi-continuous

- steam consumption: 450kg/T oil

- phosphoric acid:

- electric consumption: 28kwh/T oil

- Bleaching earth consumption: 5~50Kg/Toil

- Waste bleaching earth oil content: <35%

- Deodorization loss consumption: ≤0.5%

Mini Oil Extraction and Refining Machines for Complete Oil Mill Plant. To build an oil mill factory for cooking oil production, oil extraction machine and edible refinery machine are necessary investment. Many customers, especially those who needs to buy these equipment from other countries worry about to buy inferior equipment at high price .

- What is Soyabean oil refinery by tinytech?

- Soyabean Oil Refinery by Tinytech comes in various capacities ranging from entry level small scale plant of 5-TPD to medium and big scale plants upto 30-TPD. We are leading manufacturers and exporters of Soyabean Oil Refinery Plant systems for processing the crude soya oil into the refined soya oil.

- What is soya oil refining?

- Refining technology means separating impurity from oil in order to enhance stability and purity of oil. Soya oil refining can be utilized in order to ensure procurement of best quality oils at vary less cost. We have experience of installing more than 12 soya oil refining projects with successful startup and productions.

- Which countries produce soybean oil in the world?

- The major Soybean producing countries in the world are USA, Brazil, Argentina, China, India, Uruguay, Ukraine, Bolivia, Nigeria, South Africa Complete Turnkey 60 TPD Soybean Oil Mill Installed in Ethiopia Feel free to inquire for detailed information about soya bean oil extraction plant and soybean oil mill machinery.

- How to set up a soybean oil mill plant?

- Here we have listed some of the basic machinery required to set up Soybean Oil Mill Plant Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration.

- What is soybean oil?

- Soyabean Oil is primarily obtained from the Soya Beans. This Soyabean Oil is one of the most widely consumed recent oils. Most soybean oil is filtered, refined or sometimes even blended / hydrogenated. It has a good balance of fatty acids. It has very high protein ingredient.

- What are the basic processes of soybean oil production plant?

- Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions. Seed cleaner is used to remove the big and small impurities such as iron, stones, clump, dust, plant leaf, etc.