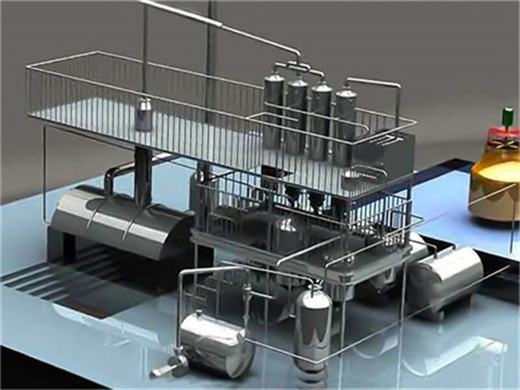

Sunflower Oil Refinery Plant Machine

- Usage: Cooking Oil

- Type: Used Cooking Oil Refinery

- Production Capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Power(W): Used Cooking Oil Refinery According to your request

- Dimension(L*W*H): Used Cooking Oil Refinery According to your request

- Weight: Used Cooking Oil Refinery According to your request

- Processing: Batch-type or Semi-continuous

- Electric Consumption: 28Kwh/T Oil

- Soften Water:

- Phosphoric Acid:

- Bleaching Earth Consumption:

- Refining Rate:

- Waste Bleaching Earth Oil Content:

- Circulating Water Cooling Water Yield:

- Supplier Type:

- ITEM: Used Cooking Oil Refinery

Bleaching. This is one the important stage in total refining process. Where the oil is heated to 100°C to 105°C and mixed with Bleaching earth chemical ( Acid Activated Clay) and also activated carbon in a vessel under vacuum at 70 mmHg where the stirring continues for specific designated time and then filtered the oil to remove the clay and carbon.

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

Tinytech Plants, Oil Mill Machinery, Tinytech Mini Oil Mills ..

- Usage: Cooking Oil

- Type: oil refinery machine

- Voltage: 380V

- Power(W): 222KW

- color: silver

- Main export countries: Asia,Africa,Latin Americ...

- Processing: Cooking oil refinery machine

- Electric consumption: 28Kwh/T oil

- soften water: 150Kg/T oil

- Phosphoric acid: 2~3 kg/T oil

- Bleaching earth consumption: 3-5Kg/Toil

- Refining rate: refining consumption 1%

- Waste bleaching earth oil content: 25% to 35 %

- Circulating water cooling water yield: 150M3/H

'TINYTECH PLANTS', established in the year 1983, is the pioneer in oil mill machinery, palm oil mill machinery, refinery plants not only in India but we have large customer base all over the world in 119 countries. 'TINYTECH PLANTS' began by manufacturing Mini oil mills to produce oil from any kind of oil seeds.

From soybean oil to sunflower oil, this adaptable equipment caters to a wide range of refining needs, providing flexibility and convenience to producers across the globe. ### Investing in Success For small-scale palm oil producers, investing in a small palm oil refinery machine is a strategic decision that can yield significant returns.

Batch Oil Refinery Plant

- Usage: Cooking Oil

- Type: refined Cooking oil in 1 liter pet bottles

- Production Capacity: 1-150t/d

- Voltage: 380V

- Power(W): 20-50KW

- Dimension(L*W*H): depond on capacity

- Weight: depond on capacity

- Main export countries: Asia,Africa,Latin American...

- Packaging: Glass Container,Plastic Container

- Grade: first Grade

- Extraction Type: Solvent Extraction

- oil content: 35%-48%

- fatty: 40~60.7

- protein: 20~37.2

- phosphlipid: 1.25~1.75

- saccharides: 5~15

- residual oil: <=1%

Process Description for Batch Type Oil Refinery Plant. Following are the basic processes of batch oil refining: De-Fatting Section. The crude oil is pumped to Reactor Vessels from storage tank & it is treated with weak solution of suitable degumming agent for removing gums.

Business Scope of Sunflower Oil Extraction Machine. 1-2000tpd sunflower oil pretreatment and pressing plant; 30-2000tpd sunflower oil solvent extraction plant

Mini Oil Refinery Plant

- Usage: for different kinds of crude oil

- Type: For Cooking oil refining machinery usage

- Production Capacity: 100-500 ton

- Voltage: 380V 440V

- Power(W): As Cooking oil refining machinery output every day

- Dimension(L*W*H): Depend on Cooking oil refining machinery capacity

- Weight: As Cooking oil refining machinery capacity

- Item: Cooking oil refining machinery

- Material: Stainless steel

- Refining process: Degumming, Bleaching, Deodorizatizing

- Grades of refined Cooking oil: one grade, two grade, three grade,

- Temperature of deodorization: 280degree

- Consumption of white clay: 1-3%

- Phosphoric acid: 0.2-0.3%

- Soften water: 150kg /ton

- Alkali consumption: 0.8-1.5kg /ton crude oil

- Circulating water: 1-2cm3 /ton crude oil

This versatile mini oil refinery works on soyabean oil, sunflower oil, palm oil, cottonseed oil, coconut oil as well as peanut oil. The input shall be the Filtered Crude Oil and the corresponding output shall be the RBD Refined Oil.

Sunflower Oil Refinery Plant In India, Sunflower Oil Machinery

- Usage: Cooking oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: High

- Voltage: Depend on the capacity

- Power(W): Depend on the capacity

- Dimension(L*W*H): Depend on the capacity, Depend on the capacity

- Steam consumption: 450kg/T oil

- Waste bleaching earth oil content: Less than 35%

- Color: Oil Refinery Process

- Use: Use used Oil Refinery Process to make oil

- Residual oil in meal: Less than 1%

- Crude oil moisture and volatile matter: Less than 0.30%

- Item: Oil Refinery Process

High-Quality Sunflower Oil. With the help of state-of-the-art sunflower oil machinery, a refinery plant can refine crude sunflower oil into high-quality sunflower oil suitable for cooking, baking, and other uses. The sunflower oil refining process removes impurities and ensures that the oil meets the desired standards.

- What is sunflower oil refinery plant?

- Sunflower Oil Refinery Plant is a machinery setup manufactured and developed to refine the crude sunflower oil with the key step of elimination of impurities from that crude oil. We at Tinytech Udyog offer small scale to medium scale Sunflower Oil Refinery Plants on Turnkey basis.

- How sunflower oil refining is successful?

- Sunflower Oil Refining becomes successful with the help of series of treatment processing being made through equipments in controlled conditions. Every refinery equipment leads to betterment in the oil quality. Clients can convert crude sunflower oil into refined sunflower oil on Tinytech Sunflower Oil Refinery Plant full of technology.

- What is a batch type sunflower oil refinery plant?

- Our Batch Type Sunflower Oil Refinery Plant will give High-Quality Refined Sunflower Oil as Output. Neutralization Reactor: For acid refining, alkali refining and water washing. Decolorization Reactor: To Bleach the Oil and remove pigment from oil. Deodorization Reactor: Removes odor from oil.

- Why should you refine sunflower oil on tinytech refinery machine?

- Refining the crude sunflower oil on our Tinytech refinery machine will eventually produce an additive free product having good oxidative, flavor and cold-test stabilities. Idea about our Sunflower Oil Refinery can be obtained by going through the below pictures.

- How to make sunflower oil edible?

- The extracted sunflower oil should be processed further to make it an edible product. Edible oils are refined to improve their flavor, odor, color and stability. The refining process will remove contaminants such as phosphatides, free fatty acids and pro-oxidants. Apart from the normal refining steps, some oils and fats need further processing.

- What is sunflower oil dewaxing?

- The process of dewaxing is carried out especially for Sunflower Oil to remove those waxes. The by-products of dewaxing can be further processed to create value-added products or reduce costs. Sunflower oil is liquid at room temperature. The refined oil is clear and slightly amber-colored.