Setting Up An Edible Oil Refinery Plant

- Usage: Cookingbean crude oil refinery

- Type: Cookingbean crude oil refinery

- Production Capacity: 1T~10TPD

- Voltage: 220V/380V

- Power(W): according to capacity

- Dimension(L*W*H): depend on capacity

- Weight: according to capacity

- Purity: high

- Application: crude oil such as Cooking oil

- Operating ways: safe and simple

- Brand: Qi'e

- Oil grade: high

- Cultivation Type: organic

- Processing Type: refined

- Refining technics: batch refining, semi-continuous

- Moisture and volatile: 0.08%

If you’re looking to get into the edible oil refining business, this article covers all the key steps and considerations that will help you set up an edible oil refinery plant. Make sure you carefully consider each of these points before you reach out to any edible oil refinery plant manufacturers in India or abroad.

Refining crude oil into edible oil requires deep process knowledge—from degumming, neutralization and dewaxing through to bleaching, deodorizing and GE and 3-MCPD mitigation. Edible oil producers worldwide rely on Alfa Laval know-how to remove impurities and volatile components and optimize refining processes.

40Tpd Soybean Processing Plant Installed In Zambia Oil Expeller And Oil Refinery Machine

- Usage: PLC oil refining machine

- Type: PLC oil refining machine

- Production Capacity: 10T-3000T/D PLC oil refining machine

- Voltage: 220V/380V

- Power(W): depend on the mode of the PLC oil refining machine

- Dimension(L*W*H): depend on the mode of PLC oil refining machine

- Weight: depend on the mode of the PLC oil refining machine

- item: PLC oil refining machine

- production process: degumming,decolorization,deacidification,deodorization

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Waste Bleaching Earth Oil Content: 25% to 35 %

- Electric Consumption: 28Kwh/T Oil

- Soften Water: 150Kg/T Oil

- Phosphoric Acid: 2~3 kg/T Oil

- Bleaching Earth Consumption: 3-5Kg/T Oil

- Supplier Type: Manufacturer

- Steel material: Stainless

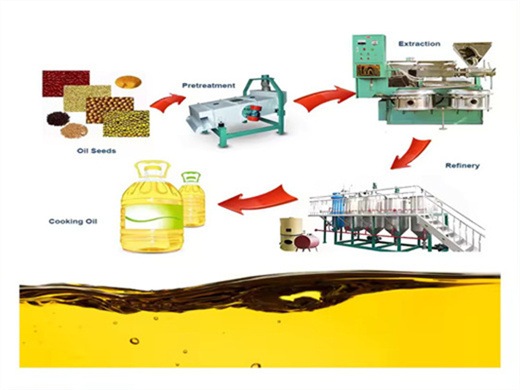

40 Ton Per Day Soybean Processing Line is installed on Turnkey Basis in Zambia. A complete soya bean processing plant includes various processes such as soybean cleaning, soybean destoning, soybean cracking, hulls separations, soybean extrusion, oil pressing, crude oil filtration, cake cooling and cake bagging section.

Soybean Oil Extraction Process. Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

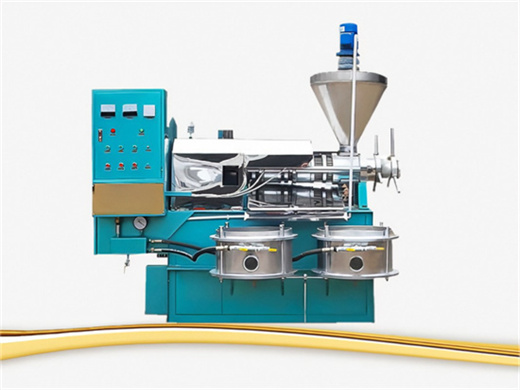

Small Scale 50Tpd Edible Oil Refining Machines

- Type: oil decoloration machine

- Use: oil refining machine

- Product type: crude oil decoloration machine

- Steam consumption: 450kg/T oil

- Phosphoric acid: 2~3kg/T oil

- Electric consumption: 28kwh/T oil

- Bleaching earth consumption: 5~50Kg/Toil

- Waste bleaching earth oil content: <35%

- Deodorization loss consumption: ≤0.5%

- Certificate: ISO9001, BV, CE

- Outstanding: low price,fast return

- Price: Negotiation

It is a small refining equipment used to refine edible oil and oil. It can also be called the refining equipment of edible oil. The oil refiner can remove the impurities in the edible oil and make the edible oil have a longer storage period, better color and smell, and more green and healthy.This equipment can produce high-cooking oil or salad oil.

Kokeb Kana Oil Kokeb Kana Edible Oil Experience the art of cooking with our exquisite food oil. Sourced from the finest ingredients and expertly blended, it not only adds a delightful richness to your recipes but also provides essential nutrients, allowing you to create wholesome and memorable culinary masterpieces. Read More Manufacturing Kokeb Kana Oil

Cottonseed Oil Refinery Plant Process Oil Expeller And Oil Refinery Machine

- Usage: Cooking Oil

- Type: Cooking extraction and Cooking oil refinery

- Production Capacity: 1-1000T/D

- Voltage: 380V,50Hz,three phase

- Product name: Cooking and Cooking oil refinery

- Using: squeezing,extraction Cooking,oil refinery for Cooking oil

- capacity: 45t/h

- business scrop: 1t-1000t/d

- voltage: 380v

- frequency: 50hz,60hz

- phase: three phase

- warranty period: 12 months

- project: turkey project

- after-sale service: Engineers available to service machinery overse

Are You Looking to Start a New Cottonseed Oil Refinery Plant or Further Expansion? The Cottonseed Oil Refinery Plant offered by GOYUM is robust, versatile, reliable and efficient. This Cottonseed Oil Refinery Plant is based on practically proven technology which is not only energy efficient & environment friendly, but also economical.

Soybean Oil Processing Plant Cooking Oil Refinery Plant ..

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 20-2000TPD

- Voltage: 380V±10%

- Power(W): standard

- Dimension(L*W*H): standard

- Weight: standard

- After-sales Service Provided: Overseas third-party support available

- Brand: Huatai

- Production name: 20t/d Cooking crude oil refining machine

- Manufacture range: 10-1000T/D

- Capacity: 20t/d

- Aavilable raw seed: Cooking

- Cooking oil yied: 15-20%

- Cooking bean oil yied: 12-18%

- Oil color: Light yellow

- Materials: Carbon steel Q234R/ Stainless steel SS304/316

- Residue in cake: less than 1%

Degumming. Crude soybean oil contains a relatively high concentration of phospholipids compared with other vegetable oils. Degumming is a process of removing these components from crude soybean oil to improve its physical stability and facilitate further refining.

- What is soybean oil refining plant?

- The soybean Oil Refining plant purifies and improves the quality of crude soybean oil by removing impurities, free fatty acids, and undesirable substances like phospholipids, waxes, and pigments.

- What is soybean oil production line?

- The soybean oil production line includes the soybean pretreatment process, soybean pre-pressing process, soybean oil extracting process, and soybean crude oil refining process. Our advanced soybean oil equipment, such as solvent extractors and automatic control systems, ensures high yields and consistent quality of both crude and refined oil.

- What is a large-scale soybean oil production plant?

- A large-scale soybean oil production plant involves several interconnected processes to efficiently extract oil from soybeans and produce high-quality refined soybean oil. The soybean oil production line includes the soybean pretreatment process, soybean pre-pressing process, soybean oil extracting process, and soybean crude oil refining process.

- Are soybean oil production lines eco-friendly?

- Yes, eco-friendly options include recycling soybean meal as animal feed, converting biomass waste into biofuel, and implementing water treatment systems to reduce effluent impact. What are common maintenance practices for a soybean oil production line?

- How is soybean oil extracted?

- The pretreated soybean flakes are sent to the soybean solvent extraction plant. The soybean oil extraction plant uses a kind of solvent (normal hexane) to absorb the oil from the soybean, and then the machines separate the solvent from soybean crude oil. The solvent can be recycled, and the soybean crude oil is refined by an oil refinery plant.

- How to set up a soybean oil mill plant?

- Here we have listed some of the basic machinery required to set up Soybean Oil Mill Plant Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration.