Cost Of Setting Up A Rice Bran Oil Refinery Plant

- Usage: Cooking Oil

- Type: Cooking oil refining equipment

- Production Capacity: 100-3000TPD

- Voltage: 220V/380V

- Power(W): 22kw

- Dimension(L*W*H): According to the Capacity

- Weight: depend on the mode

- Item: Cooking oil refining equipment

- Production process: mix with Phosphoric acid, Alkali hot water,filter, bleach, steam

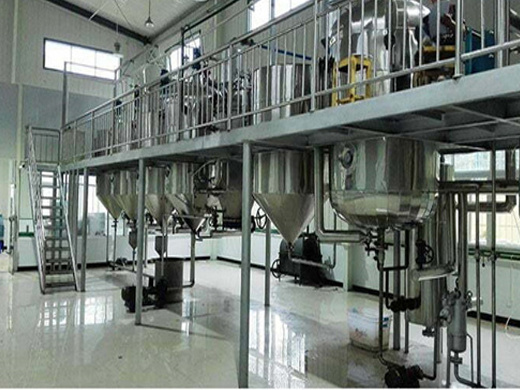

- Steel Material: Stainless

- Phosphoric acid: 2~3 kg/T oil

- Alkal: acid value*1-3kg/T oil

- Bleaching earth consumption: 3-5kg/T oil

- Power consumption: 28Kwh/T oil

- Steam consumption: 900KG/T oil

- Water(soften water): 150Kg/T oil

- Waste bleaching earth oil content: <25~35%

1.Plant land cost. The rice bran oil refinery plant land cost varies from the land scale and land location. The bigger the land scale, the better the land location, the higher the plant land cost. And whether to buy plant land, lease plant land or have own land to set up rice bran oil refinery will also affect the investment cost. Rice bran oil

Single Palm Oil Press Machine Price: Referring to single screw pressing type of palm oil processing machine, a small oil press is generally priced at around $2,000.00 $3,000.00, while for complex palm oil press machine for industiral oil mill plant, with a main motor of 18.5 kW and have a packing dimension of 255 x 170 x 205 cm, the price is

Cooking Oil Refinery Machine From China Myande

- Usage: Cooking.

- Type: cooking oil filter

- Production Capacity: high

- Voltage: 220V, 220V/ OTHER

- Power(W): 7.5kw

- Dimension(L*W*H): as per your capacity

- Weight: 1500kg

- Application: cooking oil filter

- Warranty: One Year

- Material: Carbon Steel

- Application range: oil bleaching section

- Machine color: Greeen

- Capacity: as per your requirement

- Model: YZCL210*5

- Price: Negotiable

- Feature: stainless steel leaf

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc.

Classification of Palm Oil Refinery Machine. Small Scale Refinery (1-20ton/d production) Medium Scale Refinery (20-50ton/d production) Large Scale Continuous Refinery (50-1000ton/day)

Edible Oil Refinery Plant Edible Oil Refinery Latest Price ..

- Usage: Cooking Oil refining machine

- Type: Cooking oil refining machine

- Production Capacity: 98%-100%

- Voltage: 380V/50Hz

- Item: oil making machine Cooking and Cooking oil press machine

- Supplier type: factory

- Refining rate: Refining consumption Less than 1%

- Texture: Mild steel and SS

- Steam consumption: 500Kg per ton

- Solvent consumption: Less than 250g per ton

- Electric consumption: Less than 10kwh per ton

- Bleaching earth consumption: 3-5Kg/Toil

- Processing: Oil press, extraction, refinery

1-10tpd batch type edible oil refinery plant, small scale c Small scale edible oil refinery plant for processing crude s Small scale edible oil refinery plant, cooking oil refining Industrial batch neutralizer, capacity: 1000 ton/day; Offline industrial edible oil project consultancy services, Automatic oil refinery plant

The Metso Outotec Gold Refining Plant is the result of more than 30 years’ experience in developing robust and cost-effective solutions for precious metals recovery and refining. The process has been successfully applied worldwide in installations with annual gold refining capacities from 1 to 50 tons. The gold refining process is

Refinery Plant At Best Price In India

- Usage: Cooking oil;

- Type: Cooking Oil Refinery Machine

- Production Capacity: 100%, 99%

- Voltage: 380V

- Power(W): less than 85KW

- Dimension(L*W*H): according to the specification

- Weight: about 35ton

- type: Cooking oil refining equipment

- Raw materials: Cooking, cutton seed

- Material of equipment: stainless steel and carbon steel

- including: machines,installation,tech consulting after sales

- operattion: automatic and safe

- Capacity: 1T to 500T

- color: according to your need

- Warranty period: 1 year

Automatic gold refining plant; 1-10tpd batch type edible oil refinery plant/ small scale co Rtc 360 plant & refinery scanning services; Neutralization plant, capacity: 20 tpd and above

How Much Does It Cost To Start A Palm Oil Refinery Plant

- Usage: according to the capacity for Cooking oil refinery in ukraine, machines for Cooking oil refinery in ukraine

- Type: according to the capacity Cooking oil refinery in ukraine

- Production Capacity: according to the capacity for Cooking oil refinery in ukraine

- Voltage: according to the local voltage, 220V/380V

- Power(W): according to the capacity for Cooking oil refinery in ukraine

- Dimension(L*W*H): according to the capacity for Cooking oil refinery in ukraine, 20*15*7m

- Weight: according to capacity for Cooking oil refinery in ukraine

- Refining technics: batch refining

- Cultivation Type: organic

- Moisture and volatile: 0.08%

- Purity: edible

- Residual oil in cake: low

- Color: any color as your requirement

The cost to start a palm oil refinery plant involves many aspects which includes raw material costs or crude palm oil costs, transportation costs, palm oil refinery machines costs, palm oil refinery plant construction costs, electricity Cost of fuel, cost of maintenance of palm oil refinery machine, etc.

- What is a refinery operating cost?

- A refinery operating cost can be classified under the following heads: Personnel cost. This includes salaries and wages of regular employees, employee benefits, contract maintenance labor, and other contracted services. Maintenance cost. This includes maintenance materials, contract maintenance labor, and equipment rental. Insurance.

- Can a joint-ownership refinery be economically viable?

- For a refinery to be economically viable, its operating cost must be minimized. Joint-ownership refineries are built and operated with these objectives in view. Large throughput refineries can be built with initial investment spread over the resources of two companies instead of one.

- How does operating cost affect refinery profit?

- As many operating cost elements, such as depreciation, insurance, and personnel, cost remain constant with refinery throughput, operating cost per barrel crude processed is reduced, thereby increasing refinery profit for the participants.