Spent Bleaching Earth Recovery Of Used Motor-Oil Refinery

- Usage: Cooking Oil

- Type: Cooking oil refining equipment

- color: Cooking oil refining equipment

- Main export countries: Asia,Africa,Latin Americ...

- Processing: batch-type or semicontinuous

- Electric consumption: 28Kwh/T oil

- soften water: 150Kg/T oil

- Phosphoric acid: 2~3 kg/T oil

- Bleaching earth consumption: 3-5Kg/Toil

- Refining rate: refining consumption 1%

- Waste bleaching earth oil content: 25% to 35 %

- Circulating water cooling water yield: 150M3/H

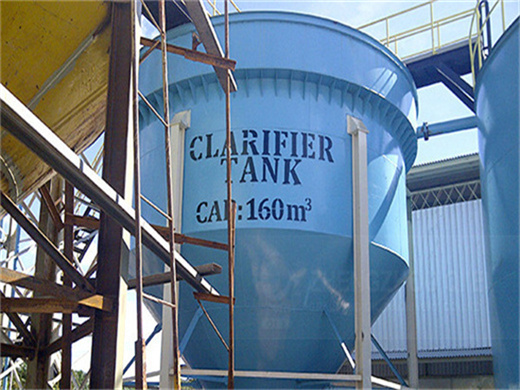

Civil Engineering Journal Vol. 4, No. 3, March, 2018 573 about 80 to 140 kg of filtered clay per ton of refined used oil is generated in this process. Taking into account the initial economic

Worldwide, Myande has supplied more than 500 oilseed crushing lines and more than 150 oil refinery lines, including 30 oil refinery production lines with capacity above 800t/d and 20 oil refinery production lines with capacity above 1,000t/d. The picture below shows location refinery plant equipment Myande has supplied.

Bentonite Bleaching Earth Used Oil Refinery

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 20-2000T/day

- Voltage: 380V

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Commodity: Cooking Oil Refinery

- Area Needed: According to the capapcity

Experience the amazing versatility of bentonite bleaching earth used oil refinery available only at Alibaba.com. Take advantage of exclusive deals and discounts on bentonite bleaching earth used oil refinery from trusted sellers.

For best describing the process within the adsorbent and with a high correlation coefficient (R 2 value > 0.999), kinetic data were best fitted by the Pseudo-second order kinetic model and this result indicates that this adsorbent provides a good medium for the re-refining of waste lubricating oil.

Sunflower Oil Refining Process Essentials For Optimal Effects

- Usage: oil refining equipment

- Type: Cooking Oil Refinery Machine

- Production Capacity: 500 TPD cooking oil refining

- Voltage: 220V/380V/440V

- Power(W): depend on capacity

- Dimension(L*W*H): depend on capacity

- Weight: depend on capacity

- After-sales Service Provided: Overseas service center available

- Keywords: cooking oil refining equipment

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business type: manufacturer

- Methods: oil refining equipment

- oil rate: 20%-98%

Start Profitable Sunflower Oil Refining Plant Supported by Professional Techniques. This article focuses on the proven sunflower oil refinery process, providing relatively accurate process parameters, effectively improving the efficiency of sunflower oil refining, reducing oil refining losses and lowering production costs.

Soyabean Oil Refinery by Tinytech comes in various capacities ranging from entry level small scale plant of 5-TPD to medium and big scale plants upto 30-TPD. We are leading manufacturers and exporters of Soyabean Oil Refinery Plant systems for processing the crude soya oil into the refined soya oil.

Groundnut Oil Processing Plant Groundnut Oil Refining Machine

- Usage: Cooking Oil

- Type: edible oil purifier

- Production Capacity: high

- Voltage: 380V

- Power(W): low power consumption

- Dimension(L*W*H): up to specification

- Weight: up to specification

- Workshop: Refining workshop

- Specification: 3~1000T/D

- Refined oil: The best grade

- Material: Stainless steel

- Adavanced technology: patent product

- Deacidification type: Physical,no soap-stocks

- Deacidification & deodorization method: Distillation

- Suitable crude oil: pressing oil and extraction oil

- Refining loss: The lowest refining loss

- Color of oil: Clear and transparent

A groundnut oil refinery plant is an essential unit that helps to purify crude groundnut oil, making it safe and suitable for human consumption. The process involves using advanced groundnut oil extraction machines to extract oil from the seeds and then refining it through various stages.

Oil Refinery Plant In Hyderabad

- Usage: seeds

- Type: Cooking Oil Refinery Machine

- Production Capacity: 1-100TPD

- Voltage: 220V/380V

- Power(W): Standard

- Dimension(L*W*H): Standard

- Weight: Standard

- Raw Material: Sunflower Oil, Sesame Oil, Soybean Oil, Palm Oil, Coconut Oil,Peanut Oil, Castor Oil, etc

- Advantage: Simple Operation

- Feature: High Output

Business listings of Oil Refinery Plant, Biodiesel Refinery Plant manufacturers, suppliers and exporters in Hyderabad, Telangana along with their contact details & address. Find here Oil Refinery Plant, Biodiesel Refinery Plant, suppliers, manufacturers, wholesalers, traders with Oil Refinery Plant prices for buying.

- What is bentonite clay processing process & equipment?

- Bentonite clay needs to go through processes such as crushing, drying, grinding, and granulation to realize its thousand uses. Different end uses have slightly different processing procedures and require different equipment. Welcome to consult Ftmmachinery engineers to customize the bentonite clay processing process and equipment for you.

- What equipment is used in the processing of bentonite?

- According to the nature of bentonite, the processing equipment used mainly includes jaw crusher, impact crusher, ball mill or Raymond mill, and some auxiliary equipment, such as feeder, powder classifier, conveyor machines, dust collectors, blowers, etc.

- Does bentonite clay need a roll crusher?

- Bentonite clay has a Mohs hardness of 1-2 and a natural moisture content of about 30%. For crushing wet and sticky bentonite clay, Ftmmachinery recommends a roll crusher. Why Choose a Roll Crusher?

- What is bentonite clay?

- Bentonite, also called montmorillonite clay, is a hydrous clay mineral mainly composed of montmorillonite. Hygroscopic and viscous properties make bentonite clay a valuable binder, sealant, absorbent and lubricant in numerous industries and applications.

- What is the product fineness of bentonite powder processing equipment Raymond Mill?

- The product fineness of bentonite powder processing equipment Raymond mill is generally around 325-400 mesh. With the development of technological progress, the demand for finer powder products is increasing. Improve the ability to capture fine powder and reduce pollution to the surrounding environment.

- How do you Dry bentonite clay?

- Bentonite clay, as mined, typically contains between 25-35% moisture and requires drying to 5% to 12%. This is often accomplished through the use of a rotary drum dryer. Learn more about bentonite drying machine