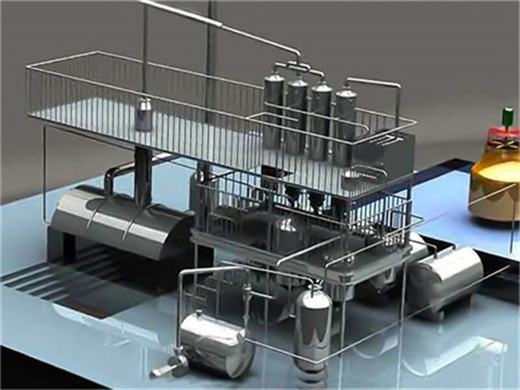

Small Scale Castor Oil Processing Cooking Oil Refinery Machine

- Usage: Cooking Oil, Edible Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: High

- Voltage: Depend on the capacity

- Power(W): Depend on the capacity

- Dimension(L*W*H): Depend on the capacity, Depend on the capacity

- Steam consumption: 450kg/T oil

- Waste bleaching earth oil content: Less than 35%

- Color: Based on Cooking oil refining machine

- Use: Cooking oil refining machine

- Residual oil in meal: Less than 1%

- Crude oil moisture and volatile matter: Less than 0.30%

- Item: Cooking oil refining machine

Castor oil extracted from castor beans is an interesting naturally derived feedstock due to the relatively large proportion of ricinoleic acid (85-90%) present in its fatty acid profile.

Entrepreneurs and castor processors in the United States and South America also cultivate castor beans but are faced with the challenge of achieving high castor oil production efficiency, as well as obtaining the desired oil quality. In this manuscript, we provide a detailed analysis of novel processing methods involved in castor oil production.

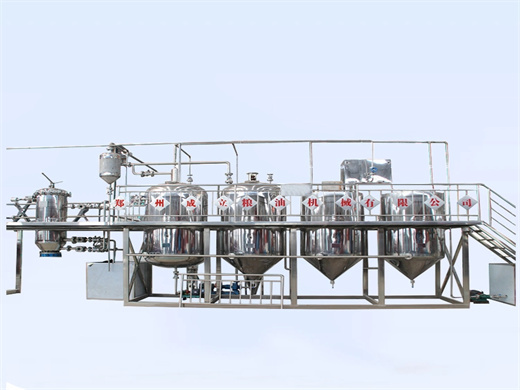

Castor Beans Oil Press Edible Oil Refinery Line

- Usage: Edible oil, Edible Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: High

- Voltage: 220V/380V/440V

- Power(W): Depend on the capacity

- Dimension(L*W*H): Depend on the capacity, Depend on the capacity

- Steam consumption: 450kg/T oil

- Waste bleaching earth oil content: Less than 35%

- Color: Based on edible oil refinery

- Use: edible oil refinery

- Residual oil in meal: Less than 1%

- Crude oil moisture and volatile matter: Less than 0.30%

- Item: edible oil refinery

Brand Name: LD Model Number: Oil Production Line; Place of Origin: China Certification: CE ISO9001 Min.Order Quantity: 1 Set/Sets Price: US $10,000 980,000/ Set Delivery Time: 35-50 days after receiving the deposit

Castor Oil Making Equipment/Castor Oil Refinery Machine Castor oil is a vegetable oil pressed from castor beans. The name probably comes from its use as a replacement for castoreum. Castor oil is a colourless to very pale yellow liquid with a distinct taste and odor. Its boiling point is 313 °C (595 °F) and its density is 961 kg/m3.

How Is Castor Oil Made: From Bean To Bottle

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 5-500 TPD

- Voltage: 440V

- Power(W): Depend

- Dimension(L*W*H): NA

- Weight: 500TONS

- After-sales Service Provided: Engineers available to service machinery overseas

The solvent is then evaporated, leaving behind the crude castor oil. Solvent extraction results in a higher oil yield but may require further refining. Step 4: Refining (if needed) Crude castor oil may contain impurities and undesirable components.

The purpose ofmustard oil refining machine/ degumming equipment/ small scale edible oil refinery is to remove the useless harmful impurity of the oil for eating, storage and industrial producing.Oil refining equipment is made up by refining tank, vacuum dewatering tank, decolorization tank, vacuum pump, oil pump, alkali tank, measuring tank

Extraction, Characterization And Modification Of Castor Seed Oil

- Usage: Cooking Oil

- Type: Cooking Oil Refinery Machine

- Production Capacity: 2-2000 T/D

- Voltage: 400/380/220V

- Power(W): electricity

- Dimension(L*W*H): 19*12*15M

- Weight: 18600KG

- Raw materials: crude vegetable oil

- Delivery time: 50 days after deposit

- Operating: easy and simple

- product: edible oil refining machine

- using life: several decades

- warranty: 1 year

- service: turn key project

- operators: 2 or 3 persons

- products: refined vegetable oil

- capacity: 1-3000 tons/day

Table 2. Physical Properties of the Crude and Refined Castor Oil Property Crude Castor Oil Refined Castor Oil Specific gravity 0.9587 0.9587 Viscosity at 28°C [St] 9.42477 6.4842 Refractive Index at 28°C 1.4686 1.4674 pH 6.11 6.34 Colour Amber Amber Table 3.

Crude Soybean Oil Maize Oil Refinery Equipment 10-1000T ..

- Usage: Cooking....

- Steam consumption: 700KG/T oil

- Electric consumption: 28Kwh/T oil

- Water(soften water): 150Kg/T oil

- Phosphoric acid: 2~3 kg/T oil

- Alkali: acid valuex1-3kg/T oil

- Circulating water cooling water yield: 150M3/H

- Bleaching earth consumption: 3-5Kg/T oil

- Waste bleaching earth oil content: less than 25~35%

- Deodorization loss consumption: ≤0.5%

- Bleaching losses: the quantity of bleaching earth multiplys 0.25%

Crude Soybean Oil Maize Oil Refinery Equipment 10-1000T Soybean Oil Machine, Find Details and Price about Oil Machine Soybean Bean Oil Machine from Crude Soybean Oil Maize Oil Refinery Equipment 10-1000T Soybean Oil Machine Shanghai Chidan Technology & Engineering Co. Ltd

- Did Abidjan I refinery crack during 2017-2022?

- The Abidjan I refinery cracking witnessed two incidents during the period 2017-2022. Societe Ivoirienne de Raffinage (SIR) is an oil and gas refining company that manufactures, produces, develops, supplies, and markets crude oil and petroleum products.

- How Castor oil is made?

- Crude castor oil is sent to the refinery plant to make high quality refined oil. The main crude oil refining process include settling and degumming, bleaching, neutralization and deodorization. Settling and Degumming: Castor oil contains gum material that affect utilization of the oil as a lubricant.

- Is castor oil a renewable oil?

- Castor oil has the reputation of "renewable oil". It contains 85%-90% ricinoleic acid, so that it has high application value in both industrial and medical field. This is one of our HOT Sale castor oil making machines - Small Vegetable Oil Manufacturing Plant. Some clients prefer to call it mini oil mill unit.

- How to start castor oil business?

- If you plan to start castor oil business for medicinal application, it is better to adopt cold pressing method. Cold pressed oil has low acid value (<1.5) and light color (Y10, R1). It can meet the international medical standard (PP grade).

- What is crude oil refining process?

- The main crude oil refining process include settling and degumming, bleaching, neutralization and deodorization. Settling and Degumming: Castor oil contains gum material that affect utilization of the oil as a lubricant. Degumming is done to remove any aqueous appearances from the lipids and remove phospholipids from the oil.

- Which countries produce castor seeds?

- The major producers of castor seeds are India, Brazil, China, Thailand, the Philippines, Pakistan and the former Soviet Union. The production of these countries account for more than 96.2% of total global production. Castor bean is high oil content oilseed. It has a worldwide demand that is rising 3%~5% per annum.